Work flow of glazed tile roll forming machine

https://www.youtube.com/watch?v=-p6uppiCUgs

Introduction of glazed tile Roll Forming Machine

The glazed tile machine has strong corrosion properties, and even direct surface contact does not react chemically.

The glazed tile machine has the characteristics of beautiful appearance, simple and elegant, exquisite and unique shape, and taste.

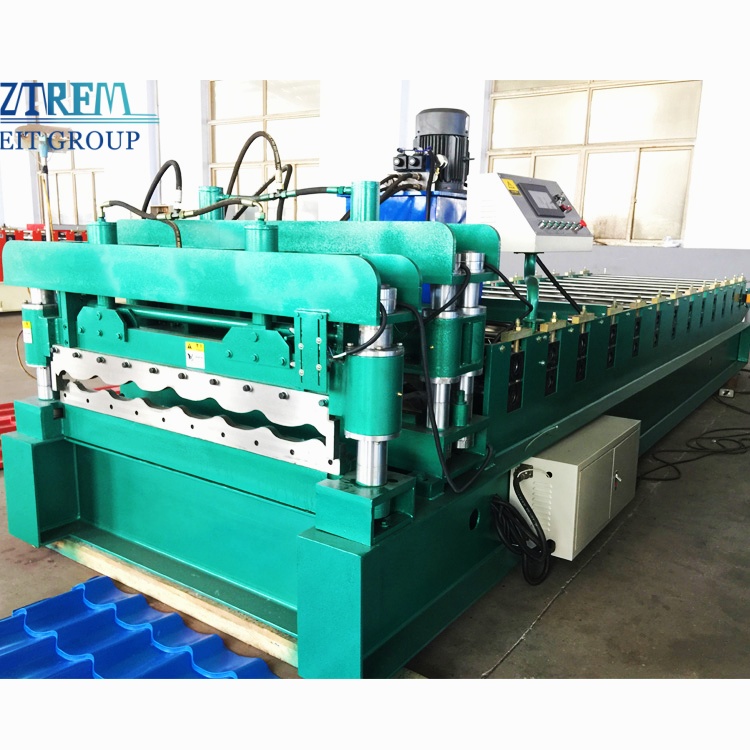

It can be widely used in garden-style factories, tourist scenic spots, pavilions, hotels, villas, exhibition halls, resorts, homes and other buildings, outdoor decoration and simple steel shed roof production. It is beautiful and generous. The glazed tile machine consists of unloading, forming, and post-forming cutting.

The products produced have a smooth and beautiful appearance, uniform paint patterns, and are widely used in industrial and civil buildings, such as factories, warehouses, motorcades, hangars, gymnasiums, exhibition halls, theaters and other rooms and walls.

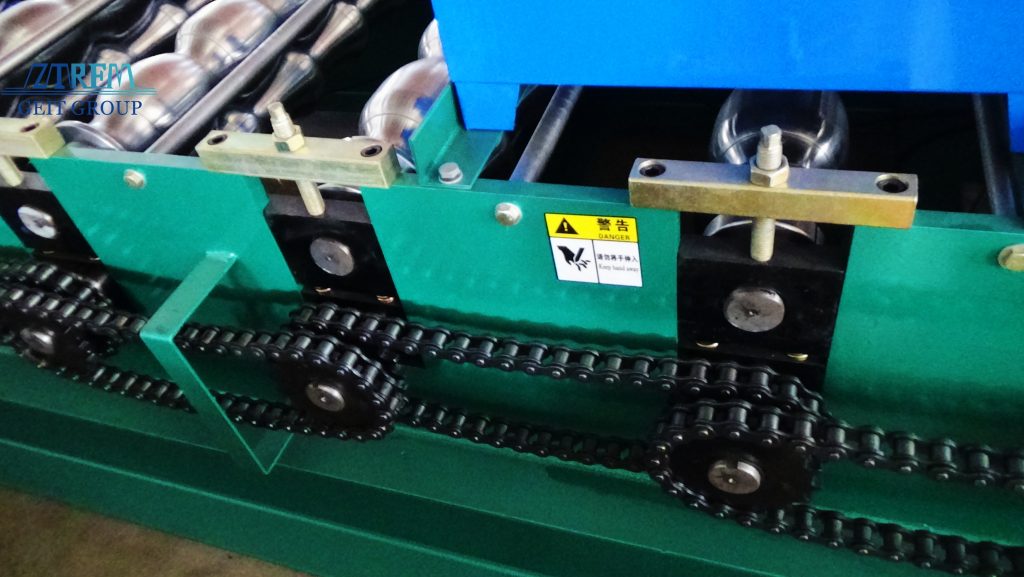

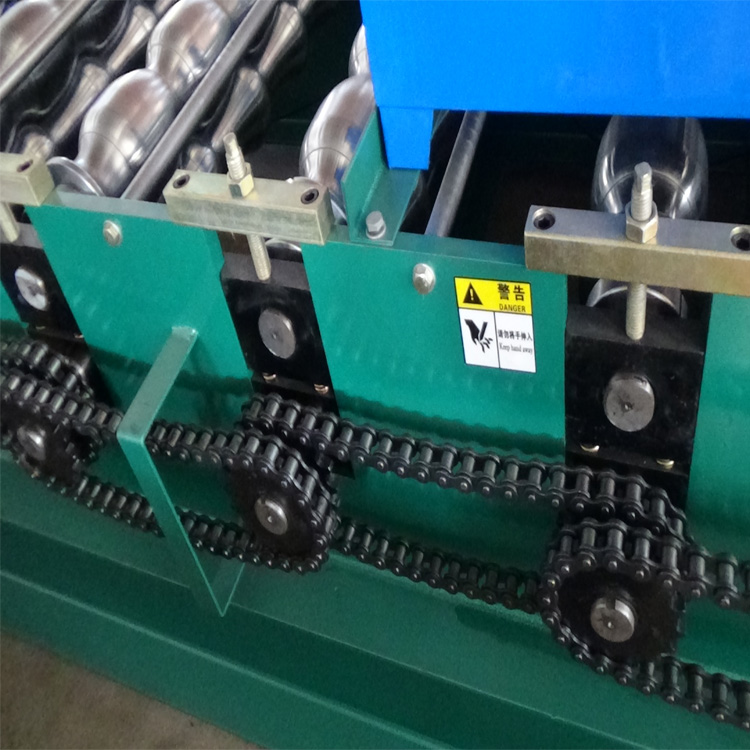

The roller forming part of the glazed tile machine is driven by a motor, and the chain drives the rollers to rotate.

The pressing part is a hydraulic cylinder that drives the mold up and down, which can press the color steel into many sections, resembling glazed tiles. The glazed tile machine has the characteristics of beautiful appearance, simple and elegant, exquisite and unique shape, and taste.

It can be widely used in garden-style factories, tourist scenic spots, pavilions, hotels, villas, exhibition halls, resorts, homes and other buildings, outdoor decoration and simple steel shed roof production, and it is beautiful and generous.

The glazed tile machine is mainly composed of a feed introduction platform, an automatic shearing device for steel plate forming, a hydraulic system, a movement computer control system, and an automatic length measurement system.

The glazed tile machine consists of unloading, forming, and post-forming cutting. The products produced have a smooth and beautiful appearance, uniform paint patterns, and are widely used in industrial and civil buildings, such as factories, warehouses, motorcades, hangars, gymnasiums, exhibition halls, theaters and other rooms and walls.

The roller forming part of the glazed tile machine is driven by a motor, and the chain drives the rollers to rotate. The pressing part is a hydraulic cylinder that drives the mold up and down, which can press the color steel into many sections, resembling glazed tiles.

Positioning of the working position of the glazed tile machine

The glazed tile machine has a reasonable structure and does not require manual operation. When manufacturing the mold, it should be designed according to this requirement to avoid machine tool accidents. Always pay attention to the height of the lubricating oil in the sliding box and the machine bodies on both sides.

The equipment should be wiped frequently to keep it clean, and no mud or water should be allowed. The groove wheel installed on the hexagonal rotating wheel shaft is turned to achieve indexing positioning. A return cam conjugated with the pressing cam installed on the same shaft is installed at both ends of the upper shaft.

Colored steel glazed tile equipment, the finishing touch. It has light weight. Good performance, convenient installation, and can be widely used in villa roofs, rural flat-to-slope conversion, tourist scenic area buildings, etc.

The glazed tile machine is easy to operate, and can also be equipped with automatic loading racks and unloading manipulators and extruders, tile cutting machines, and tile support conveyor lines to form tile production lines. The positioning rod and positioning plate are used to realize the positioning of the lower mold in the working position. In the left and right chassis, there is a hydraulic press used to shape and press the rough tiles extruded and cut by the vacuum screw extruder when producing glazed tiles.

It can be installed and used alone but needs manual loading and unloading of blanks. It is equipped with a lubrication pump. When the machine is working, the oil pipe delivers lubricating oil to various friction and moving parts.

The glazed tile machine is a single roll forming unit composed of a set of rollers that can produce various specifications of pressed tile purlins. Its main components include: passive loading rack, punching device, leveling device, hydraulic station, computer control system and post-forming cutting device, etc.

Main parameters of the machine

|

1.Formed Material

|

PPGI,GI,AI,ZTRFM composite material

|

Thickness:0.18-0.8mm Width:1000mm/1250mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16 rows(As your requirement of profile)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gear and chain transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

8T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW* sets,Siemens brand

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Recommend related machine