Work flow of Double Line Light Steel Keel Drywall Profile Roll Forming Machine

https://www.youtube.com/watch?v=aYoiXDM60wA

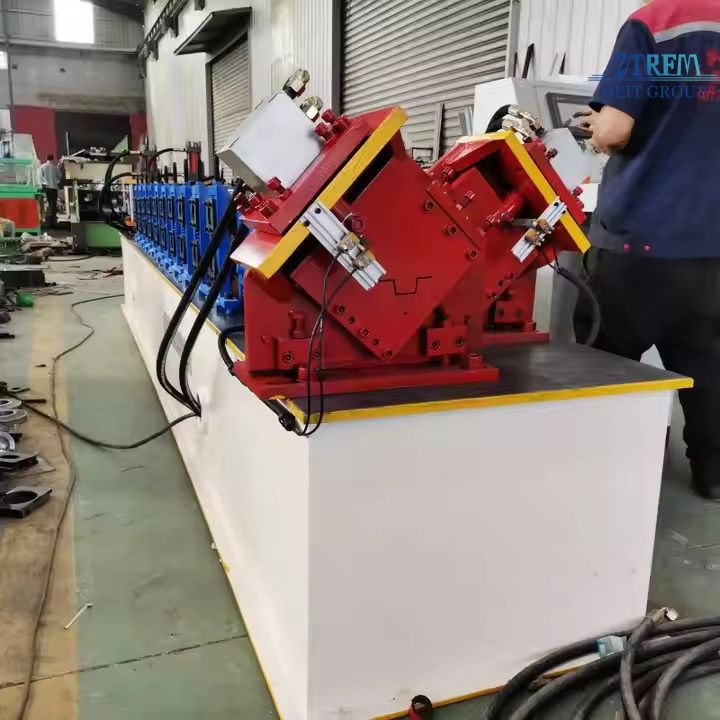

Introduction of Double Line Light Steel Keel Drywall Profile Roll Forming Machine

In today’s industrial production scenarios that pursue high efficiency and intensification, the fully automatic Double Line Light Steel Keel Drywall Profile Roll Forming Machine production line is emerging with its unique advantages—it can not only significantly reduce site occupation and manual input, but also achieve a qualitative leap in production efficiency.

In terms of space planning, this production line is a model of “meticulous calculation”. Through a highly integrated and compact structural design, it breaks the dependence of traditional production lines on large-area sites.

Even in limited workshop spaces, it can systematically complete the entire process of forming and processing light steel keels, making every inch of space exert its maximum value and saving valuable site resources for enterprises.

In terms of intelligent operation and maintenance as well as production optimization, this production line also performs brilliantly. It is equipped with an excellent remote operation and maintenance system, combined with precise high-speed servo cutting technology, allowing operators to monitor the operating status of the production line in real time through remote terminals without having to stay by the equipment all the time.

Once a fault occurs, the system can quickly locate the problem and assist in diagnosis, greatly reducing downtime for maintenance. What’s more worth mentioning is that the integrated artificial intelligence system is not static. It will continue to learn and accumulate data in continuous production practice, thereby dynamically optimizing production parameters and processes, so that the intelligence level of the entire production line will steadily improve with the increase of operating time.

For enterprises, the fully automatic Double Line Light Steel Keel Drywall Profile Roll Forming Machine production line is undoubtedly a reliable choice to reduce labor costs and enhance core competitiveness.

It replaces traditional manual operations with a fully automated operation mode, which not only reduces reliance on skilled workers and lowers the rate of human errors, but also significantly improves production efficiency on the premise of ensuring stable quality of light steel keel products, helping enterprises seize opportunities in the fierce market competition and move towards a broader development space.

The main parameters of the machine

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

0-50m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||