Work flow of M Purlin Roll Forming Equipment

Uncoiling—guiding—feeding&flatting—forming—punching&cutting—product receiving

https://www.youtube.com/watch?v=m49_kBTjBa8

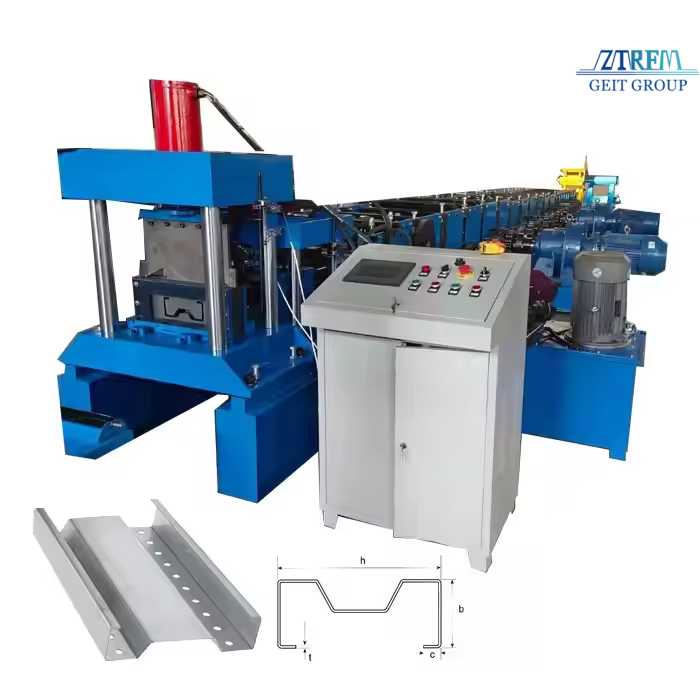

Introduction of M Purlin Roll Forming Equipment

Known as M purlin forming machines, these devices produce M purlins through roll forming that boast excellent bending and compression resistance, along with high straightness. Featuring fully automated fixed-length cutting, automatic punching, and a high level of automation, they offer convenient installation. The end products serve as main load-bearing structures in large and medium-sized industrial and civil buildings, such as roof load-bearing systems and wall supports in factories, warehouses, locomotive depots, aircraft hangars, exhibition halls, theaters, stadiums, and market greenhouses.

The sectioned or block installation method for M purlin units allows most welding and splicing work to be conducted on the ground, which helps improve project quality and saves a significant amount of assembly scaffolding. Since the division of units takes into account the capacity of on-site lifting equipment, existing site machinery can be fully utilized, reducing rental costs for lifting equipment and the transportation fees of M purlin machines, thus contributing to cost reduction.

This installation method is applicable when the divided units have sufficient rigidity and their own geometric invariance; otherwise, temporary reinforcement measures should be adopted. The construction process involves the proper division of sections/blocks and the handling during their hoisting.

M purlin equipment is a single-coil forming unit with a set of rolls capable of producing M purlins in various specifications. It mainly consists of a passive feeding frame, leveling device, punching device, post-forming cutting device, hydraulic station, and computer control system.

M purlins rolled by M purlin machines exhibit good tensile, bending, and compression performance, along with high straightness.

They come with features like fully automated fixed-length cutting, automatic punching, high automation, easy installation, and user-friendly operation thanks to the adoption of automatic flying saw punching.

These products can be used as main load-bearing structures in large and medium-sized industrial and civil buildings, including roof load-bearing systems and wall supports in factories, warehouses, locomotive depots, aircraft hangars, exhibition halls, theaters, stadiums, and market greenhouses.

Cold-formed steel, made from cold-rolled steel plates or strips, is a key material for lightweight steel structures. M purlin machines enable the production of thin-walled products, simplifying the manufacturing process and boosting production efficiency.

They can fabricate various profiles with uniform wall thickness and complex cross-sections that are difficult to produce using conventional hot-rolling methods, as well as cold-formed steel of different materials.

M purlins rolled by M purlin units offer excellent tensile, bending, and compression performance, high straightness, fully automated fixed-length cutting, automatic punching, high automation, and easy installation. They serve as main load-bearing structures in large and medium-sized industrial and civil buildings, such as roof load-bearing systems and wall supports in factories, warehouses, locomotive depots, aircraft hangars, exhibition halls, theaters, stadiums, and market greenhouses.

For M purlin units, the fabrication and inspection of welded spherical joints involve two processing methods for welded spheres: hot rolling and cold rolling, with hot-rolled spheres

Finished product display

The main parameters of the machine

|

Formed Material

|

GI

|

Thickness:1.5-3 mm (standard)

|

||

|

Main body

|

Roller station

|

18 rows (As your requirement)

|

||

|

Diameter of shaft

|

80 mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gear and chains transmission

|

|||

|

Dimension(L*W*H)

|

7500*1500*1500(customize)

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW*2 sets,Siemens brand

|

||

|

Hydraulic system power

|

7.5 KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

25 m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||