Work flow of the machine

https://www.youtube.com/watch?v=hInfpmJDoeE

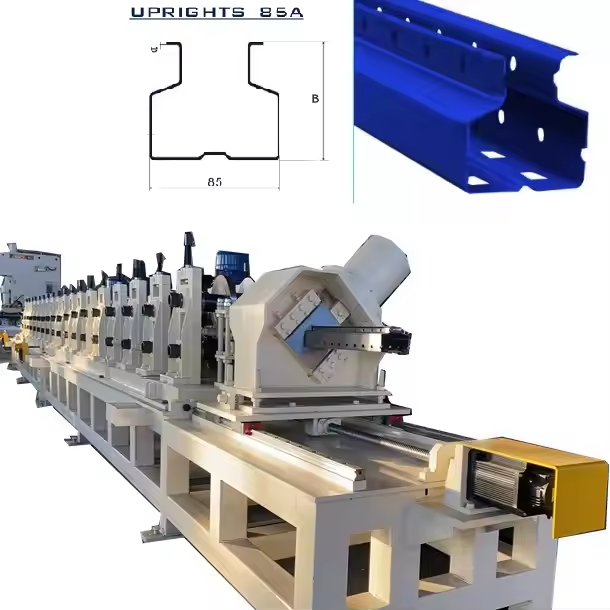

Structural Design and Operational Performance of Upright Roll Forming Machine

The upright roll forming machine is a specialized equipment designed for upright production, featuring high efficiency, high precision, and ease of operation. Its emergence has significantly enhanced the speed and quality of upright manufacturing, thus gaining favor among numerous enterprises.

1. Ease of Operation

The upright roll forming machine adopts an intelligent control system. Operators only need to set parameters simply to complete the entire production process. Most upright roll forming machines are also equipped with touch screen control panels, which are intuitive and easy to understand.

No special training is required, allowing operators to get on the job quickly.

The ease of operation not only improves production efficiency but also reduces the complexity of manual operations, alleviates workers’ labor intensity, and enhances production safety.

2. High Efficiency

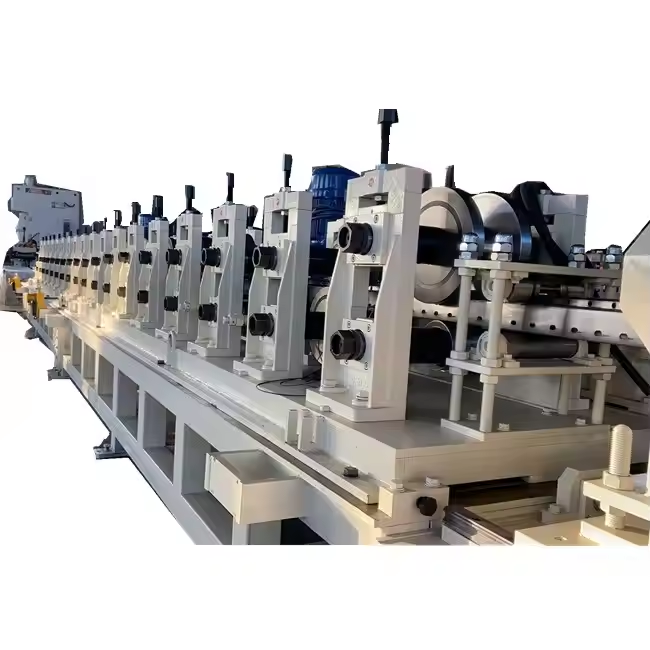

The upright roll forming machine adopts an integrated design, integrating multiple processes into one equipment.

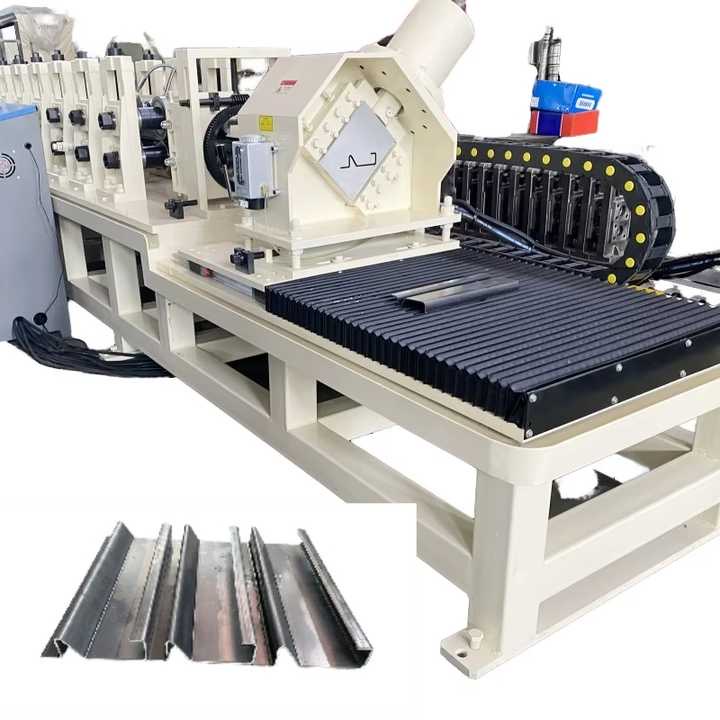

It completes the entire upright production through automatic feeding, punching and shearing, bending, forming and other processes. Compared with traditional craftsmanship, the production efficiency of the upright roll forming machine is greatly improved.

Taking traditional manual upright production as an example, a worker can only produce dozens of uprights a day, while the upright roll forming machine can produce hundreds of uprights a day, which greatly saves production time and improves production efficiency.

3. High Precision

The upright roll forming machine utilizes advanced numerical control technology, boasting high precision and good stability, which can accurately control the size and shape of uprights.

Through the built-in measurement and detection system of the equipment, it can timely monitor deviations in the production process and make corresponding adjustments to ensure that the quality of the produced uprights meets the standards.

Compared with traditional manual production, the upright roll forming machine does not rely on workers’ experience and technical level, which can ensure the consistency of the size and shape of each upright, and improve the consistency and stability of production.

4. Cost Saving

The emergence of the upright roll forming machine has greatly reduced production costs.

Due to automated production, manual operations are reduced, and labor input is lowered. At the same time, the upright roll forming machine has high production efficiency, which greatly reduces production time, improves production efficiency, and cuts down production costs.

In addition, the upright roll forming machine can also save the use of raw materials, reduce the waste of raw materials, and lower production costs. By reducing labor costs and raw material costs, enterprises can reduce the sales price of uprights and improve their competitiveness.

The main parameters of the machine

| 1.Formed Material | GI,AI | Thickness:2 to 3mm | ||

| 2.Decoiler | Automatic decoiler | Manual decoiler(will give you as free) | ||

| 3.Main body | Roller station | 20 rows(As your requirement) | ||

| Diameter of shaft | 80mm solid shaft | |||

| Material of rollers | Gcr12mov | |||

| Machine body frame | 500 H steel | |||

| Drive | Chain transmission | |||

| Dimension(L*W*H) | 9500*1600*1600(customize) | |||

| Weight | 6T | |||

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

| 5.Power | Motor Power | 7.5KW | ||

| Hydraulic system | 7.5KW | |||

| 6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

| 7.Control system | Electric Box | Customized(famous brand) | ||

| Language | English(Support multiple languages) | |||

| PLC |

Automatic production of the whole machine. Can set batch, length, quantity, etc. |

|||

| 18.Forming Speed | 15-20m/min | The speed depends on the shape of the tile and the thickness of the material. | ||