Work flow of the machine:

https://www.youtube.com/watch?v=SOiyxRfJ3as

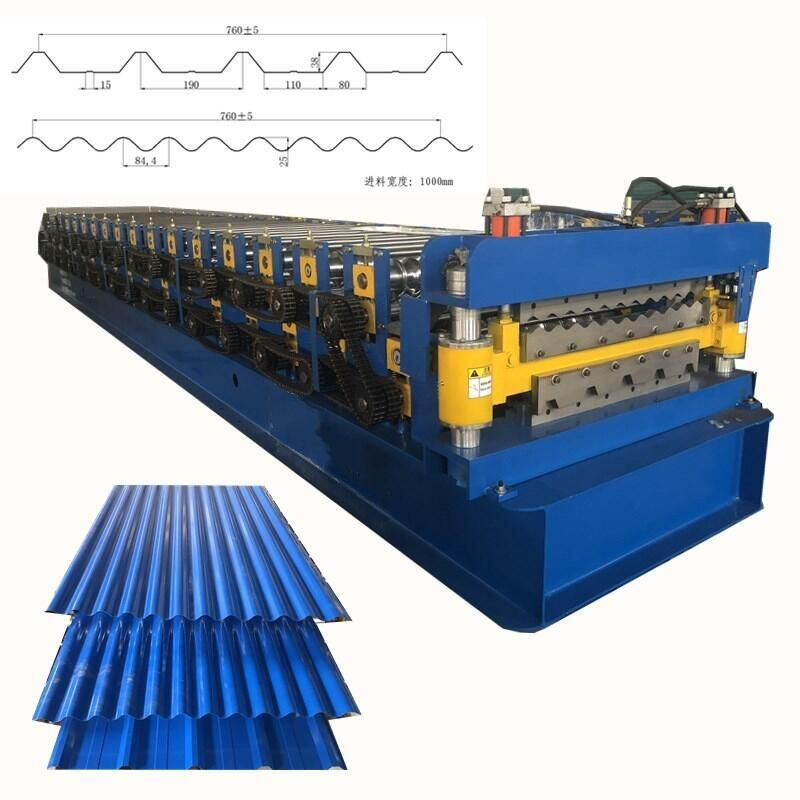

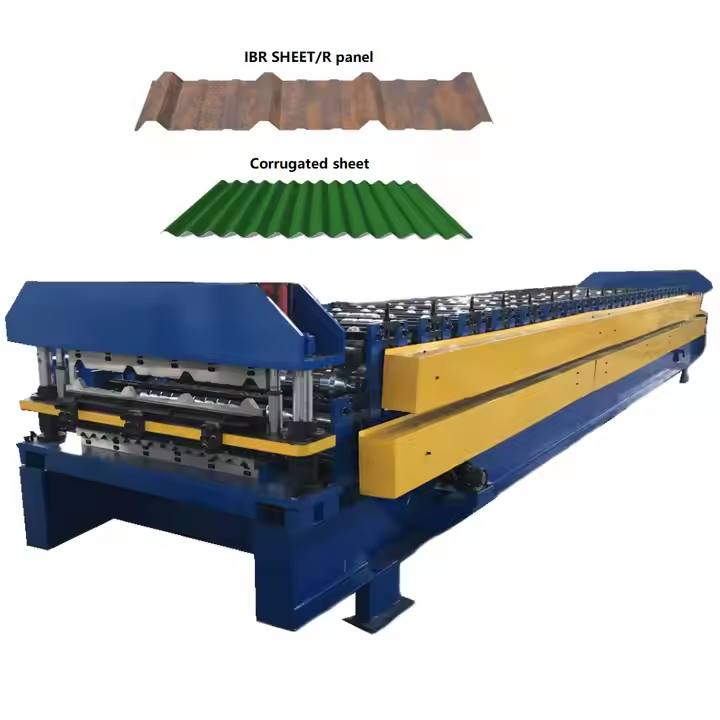

Metal Color Steel Three Layer Roof Roll Forming Machine

The three layer roll forming machine consists of feeding, forming, and post-forming cutting components.

The color steel plates produced are characterized by a flat and beautiful appearance, uniform paint patterns, and are widely used in industrial and civil buildings, such as roofs and walls of factories, warehouses, gymnasiums, exhibition halls, cinemas, and other structures.

The components of the three layer roll forming machine include: the complete color steel roll forming machine, PLC computer control system, hydraulic pump station system, and fully automatic post-shearing system.

The equipment features: this color steel plate equipment adopts automatic control software, enabling the color steel roll forming machine to realize production information management.

The automatic control system of the entire unit adopts a highly integrated network, making the performance of the automatic system excellent.

Automatic feeding and the working procedure for the color steel roll forming machine to take blanks: the mold installation and main engine test run are the same as above. Then, turn on the air compressor, vacuum pump, extruder, tile cutter, feeding machine, roll forming machine, color steel roll forming machine, and tile support conveyor. When stopping, first stop the extruder, then stop the other equipment.

There are many parameters to set for the three-layer roll forming machine, which are set through the text screen. There are two types of parameter settings: equipment parameters and user parameters. Equipment parameters include: single pulse length, overshoot, roll forming distance, roll forming time, cutter time, etc.

User parameters include: number of sheets, length, section, last section, section distance, number of sections, etc. (for the color steel roll forming machine).

The three layer roll forming machine needs to use the high-speed pulse input function, which has excellent high-speed input performance.

It selects AB phase anti-interference and uses the fixed-value interrupt function to ensure high precision.

With multi-function in one machine, it not only saves floor space but also reduces costs.

The three layer roll forming machine has a lightweight structure, making it particularly suitable for customers with limited site space and on-site construction needs.

The main parameters of the machine

|

1.Formed Material

|

PPGI,GI,AI,GL

|

Thickness:0.3-0.8mm Width:As per profile drawing

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

5Tdecoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16+18 +16 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

13T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

220V

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Recommended related machine