Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.3-0.8mm Width:1000mm/1250mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

13 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600(customize)

|

|||

|

Weight

|

11T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW

|

||

|

Hydraulic system power

|

15KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

8-9m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

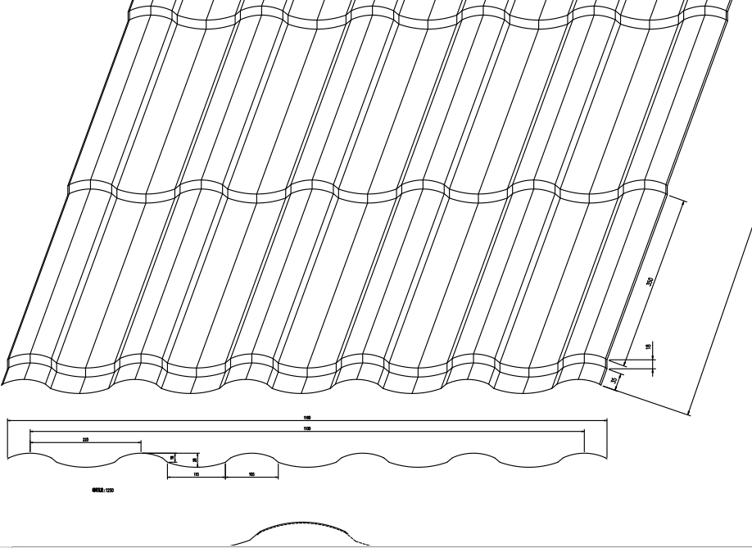

Machine Introduction:

In the field of construction, glazed tiles are favored for their beautiful and durable characteristics. As a key equipment for the production of glazed tiles, the glazed tile machine is constantly promoting the development and change of the building materials industry. Glazed tile machines usually use cold roll forming technology. Taking the common color steel glazed tile machine as an example, firstly, the raw materials such as galvanized steel plate, color steel plate or aluminum plate are placed at the feed port of the equipment. Subsequently, driven by the motor, the material is gradually rolled and formed through a series of roller tables. In this process, multiple sets of servo motor-driven rolling dies, under the precise adjustment of the digital control system, accurately process the material according to the preset parameters, and shape it into specific waves and shapes, similar to the style of traditional glazed tiles. Then, the cutter part controlled by the hydraulic system cuts the molded material to a fixed length according to the set length, and finally produces pieces of glazed tiles with accurate dimensions and exquisite shapes. Zhongtuo color steel glazed tile machine, the main body of the equipment is made of high alloy steel casting, with advanced digital control system, the color steel plate error can be controlled in a very small range, to ensure the production of high-quality glazed tile products.

Significant advantages:

1.High production efficiency:

Automated production lines and intelligent control systems, such as PLC (programmable logic controller) and touch screen operation interface, can realize automated production and real-time monitoring. It can quickly and stably form glazed tiles, and the production length is not limited, and multiple groups of different data can be easily set on the computer controller according to the construction requirements, and after one-key confirmation, the equipment automatically produces finished products of different lengths according to the set data, which greatly shortens the production cycle.

2.Good product quality:

The glazed tile machine is equipped with a hydraulic system and a precision mold design, using high-strength wear-resistant rollers and molds to ensure that the glazed tiles are highly flat during the pressing process, without deformation and scratches, and the surface is smooth and beautiful. Like the antique glazed tile forming machine of Xinnuo Machinery, the roller of the forming part is chrome-plated, which can not only protect the surface of the material from being scratched during molding, but also prolong the service life of the machine, and produce the glazed tile with reliable color and luster, with the characteristics of weather resistance, corrosion resistance, waterproof, etc., which can provide good protection for the building.

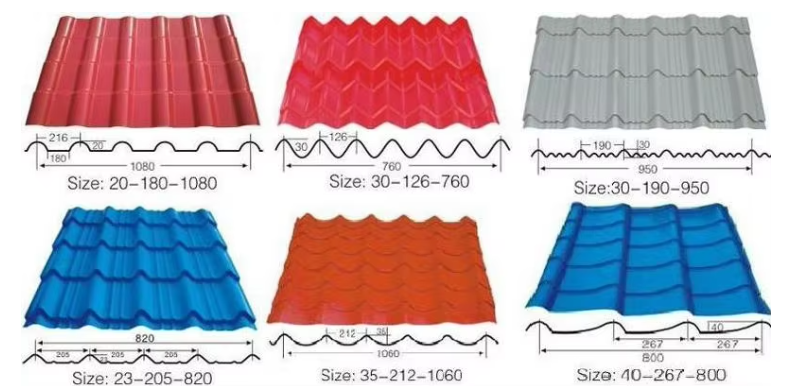

3.Functional diversification:

Some advanced glazed tile machines can produce imitation resin glazed tiles, color steel glazed tiles and other types of tiles to meet the needs of different architectural styles and customers, whether it is modern architecture or classical style architecture, can provide suitable glazed tile products.

4.Easy operation and maintenance:

The human-computer interaction interface of the glazed tile machine is friendly and easy to use, and the parameter setting is simple and intuitive, even non-professionals can easily get started. At the same time, the daily maintenance of the equipment is relatively simple, which reduces the threshold for use and maintenance costs.

5.Convenient transportation and installation:

The glazed tile machine is small in size, light in weight, easy to move and transport, occupies a small space, is convenient for transfer and installation at different construction sites, and can flexibly meet the needs of different projects, whether it is a small construction project or a large project, it can be quickly put into use.

Applications:

It is mainly used for the production of glazed tile products required for antique buildings and traditional houses, and is widely used in palaces, temples, ancient building roofs and wall decorations by processing metal plates or synthetic resin materials into various tiles through the pressing and molding process

1.Exterior wall decoration of the building:

Through the dry hanging technology, the glazed tiles are applied to the façade of the building, realizing the combination of traditional craftsmanship and modern curtain wall system, and applying it to the decoration of multi-storey and high-rise buildings, with the functions of waterproofing, heat insulation, and fire prevention.

2.Photovoltaic integrated application:

Some of the equipment is converted into solar energy by embedding photovoltaic cells, which not only retains the appearance of traditional tiles but also has the function of generating electricity, which is suitable for residential, commercial buildings and renovation of historical buildings, and has the advantages of energy conservation and emission reduction.

Products Display: