Pallet Rack Supermarket Shelf Storage Upright Beam Roll Forming Machine

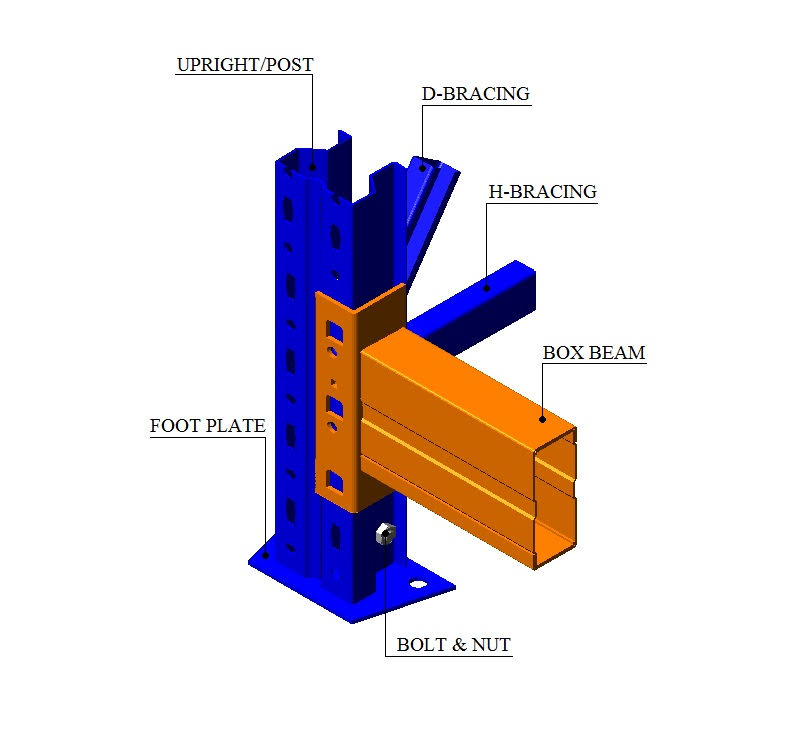

In the field of warehousing, the efficient use of space and the safe storage and convenient access of goods are the eternal pursuit. As a key component of the construction of various storage shelves, the performance of the shelf column beam equipment is directly related to the overall efficiency of the storage system. The shelf column and beam equipment does not operate in isolation, but cooperates to build a stable storage and bearing system. When the goods are ready to be put on the shelves for storage, the forklift will carry the pallets carrying the goods to the shelf area, and the operator adjusts the beam to a suitable height by using the diamond-shaped hole on the column according to the size and weight of the goods, and tightly fixes it with the column through the safety pin. The pallet is then placed precisely on the beam, through which the weight of the goods is transferred to the beam, which is then dispersed to the columns, which then transfer the gravity to the ground foundation. In the whole process, the columns and beams rely on their strong structural strength to bear the weight of the goods, ensure the stability and safety of the shelving system, and achieve efficient and orderly warehousing and storage operations.

Significant advantages:

In the warehousing and logistics system, as the key equipment for building storage shelves, the performance of the shelf column beam machine directly affects the storage capacity, operation efficiency and cargo storage safety of the warehouse. With a series of outstanding features, this type of equipment plays an irreplaceable and important role in the field of modern warehousing.

1.Strong load-bearing capacity:

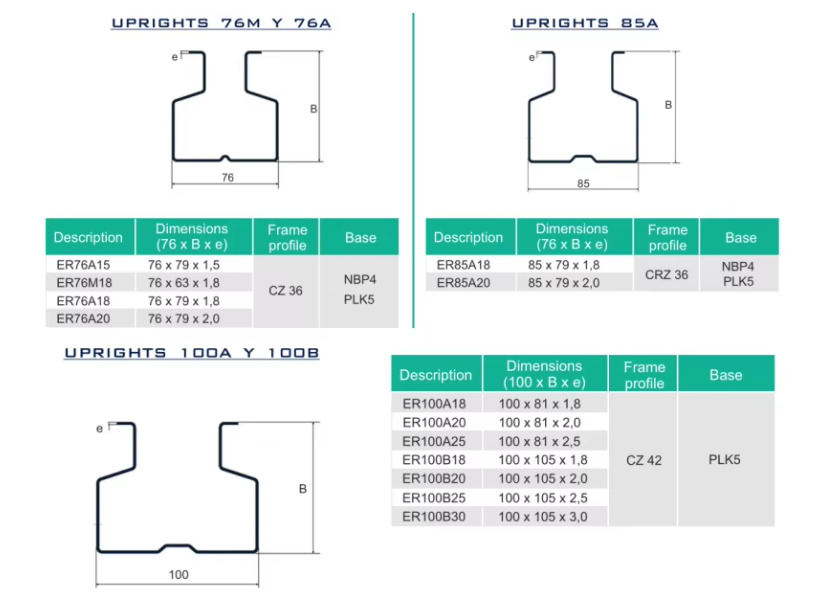

The shelves produced by the shelf column beam machine have excellent load-bearing performance. The column is usually made of high-quality cold-rolled steel plate, which is processed by advanced technology, and its unique multi-faceted structure greatly increases the inertia distance of the column. This characteristic gives the column a strong load-bearing capacity and excellent impact resistance, which can effectively avoid crack failure due to stress concentration. The beam is mostly welded by two special hug beams, the structure doubles the thickness of the upper and lower beams, and according to the steel structure design theory, it gives full play to the anti-load capacity of the material, and realizes the advantages of light weight, strong bearing capacity and low cost. In general, the load capacity of each layer of shelves is between 500kg and 5000kg, and some specially designed and customized shelves have a higher load limit. Such a strong load-bearing capacity enables the shelves to easily cope with the storage needs of various heavy objects such as heavy industrial parts and bulk commodities, and provides a solid guarantee for enterprises to store goods on a large scale.

2.Wide applicability:

The shelf column beam machine has a wide range of applicability, which can meet the warehousing needs of enterprises of different industries and different sizes. Whether it is a large-scale logistics and warehousing center, facing the throughput and storage pressure of massive goods; It is also a manufacturing factory, which needs to carry out complex and diverse classification and storage of raw materials, parts and finished products; From small retail stores where space is limited but storage areas need to be used efficiently, these machines can be used to create racking systems. In addition, according to the special needs of different industries and different scenarios, customized production and adaptation of shelves, such as for the storage needs of large parts in automobile manufacturing plants, special heavy-duty shelves are designed; For the fast delivery needs of e-commerce warehouses, we create flexible and convenient light and medium-sized shelves to truly meet diversified storage needs.

3.Convenient transport and installation:

From the point of view of transport and installation, the shelf column beam machine also has outstanding advantages. The shelving components produced are usually designed as structures that are easy to disassemble and assemble, small in size, light in weight, and take up little space during transportation, which is convenient for flexible transfer between different construction sites. The installation process is simple and clear, without professional and complex installation tools and technology, ordinary workers can quickly get started after simple training, and can complete the construction of shelves in a short time, providing strong support for the rapid progress of the project.

4.Efficient production capacity:

The shelf column beam machine itself has a high production efficiency. The application of automated production lines and advanced intelligent control systems, such as PLC (Programmable Logic Controller) and intuitive touch screen operation interface, realizes the automatic production and real-time monitoring of equipment. The equipment can quickly and stably produce columns and beams that meet the specifications, greatly shorten the production cycle of the shelves, meet the large demand of the market for storage shelves, and are especially suitable for the centralized construction of large-scale storage projects.

Application Scenarios and Industry Cases:

1. Logistics and warehousing center

In large-scale logistics and warehousing centers, the cargo throughput is huge, and the requirements for storage efficiency and space utilization are extremely high. The heavy-duty shelving system constructed by the shelf column beam equipment can carry several tons of goods on each floor, and with forklifts and other handling equipment, it can quickly realize the storage and sorting of goods, greatly improving the efficiency of logistics turnover. For example, a well-known logistics company adopted high-level shelves built by advanced column and beam equipment, which increased the warehouse storage capacity by more than 30%, and increased the efficiency of goods in and out of the warehouse by 50%, effectively reducing operating costs.

2.Manufacturing plants

The storage needs of raw materials, components and finished products in manufacturing plants are complex and diverse. The shelf column beam equipment can flexibly adjust the shelf structure and layout according to the characteristics of different items. For example, in automobile manufacturing plants, the special shelves built by such equipment can not only store large auto parts, but also classify and store small screws, nuts and other accessories, so as to realize the orderly management of production materials and improve production efficiency and workshop space utilization.

3.E-commerce warehouses

The e-commerce industry has a fast pace of order processing and requires fast access to goods. Lightweight and medium-sized shelves composed of shelf columns and beams are widely used in e-commerce warehouses. Its flexible floor height adjustment and convenient cargo access methods can meet the storage and fast delivery needs of e-commerce enterprises for various commodities, and help enterprises improve customer satisfaction and market competitiveness.

With its unique structural design and powerful functional advantages, the shelf column beam equipment occupies a pivotal position in the warehousing industry. With the continuous innovation and development of warehousing technology, this kind of equipment will continue to be optimized and upgraded, providing more efficient, intelligent and safe solutions for modern warehousing management, and promoting the level of warehousing and logistics in various industries to a new height.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-2.7mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

will give you as free

|

||

|

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

As your requirement

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

About 75T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

customized

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Products Display: