EPS sandwich panel down layer sheet machine

Introduction of the machine

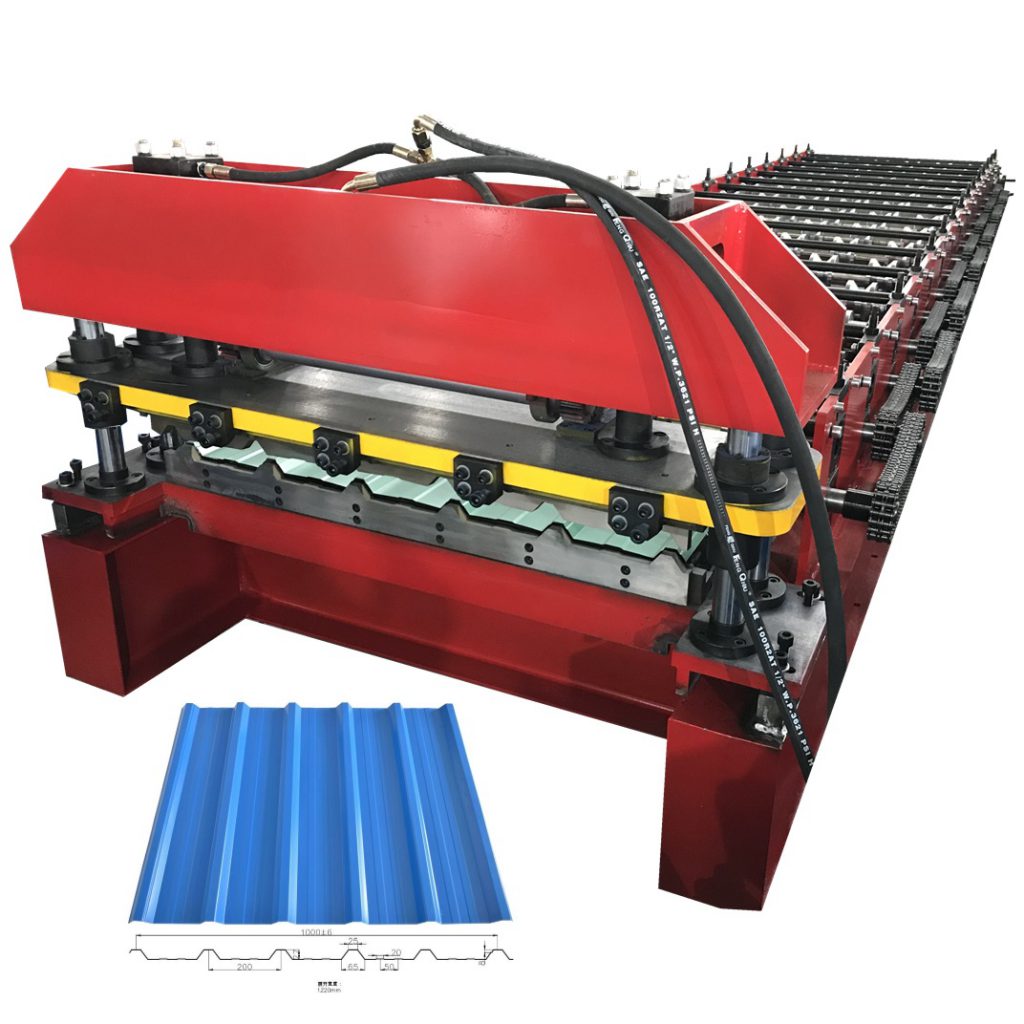

The machinery is used to produce sandwich panels composed of two layers of color-coated steel sheets and flame-retardant EPS boards bonded and compounded together. The cross-sectional schematic diagram of the color steel sandwich panel is shown in Figure 1.

With its excellent performance, EPS color steel sandwich panels are widely used in the construction of large industrial plants, warehouses, gymnasiums, cold storage, mezzanines and other fields.

Production Process and Performance

Color steel sandwich panels are bonded by three layers of materials. The outer layer is made of high-density coated steel sheets or decorative wood panels, the core material is a low-density EPS board, and the coated steel sheets and EPS boards are bonded together with adhesives.

The outer metal sheets can be ordinary steel sheets, stainless steel sheets, aluminum sheets or galvanized iron sheets. They can also be made into structures where the outer side is a decorative panel and the inner side is a metal sheet, or the outer side is a low-carbon steel sheet (or stainless steel) and the inner side is a plastic composite panel (plastic-coated steel sheet).

EPS boards are cut to the required thickness and bonded to metal sheets with adhesives, which are generally two-component polyurethane adhesives. It have the triple functions of heat preservation, waterproofing and load-bearing, and are mainly used for the walls and roofs of buildings. Therefore, the quality of the three layers of materials constituting color steel panels will directly affect the service life, durability and building safety of color steel sandwich panels.

Application of sandwich panels

Extensive application is seen for color steel sandwich panels in construction, cold storage, and other fields. Their flexible installation methods and a wide range of specification and size options make them suitable for various building types.

1. Construction sector: They can serve as building materials for roofs, walls, partitions, and other parts. Boasting the characteristics of being lightweight yet high-strength, they stand out as high-quality building materials for large-span structures like industrial workshops and warehouses, offering excellent wind resistance and earthquake resistance.

2. Cold storage sector: With heat insulation function, they are an ideal choice for cold storage construction. Their outstanding thermal insulation performance can effectively reduce heat exchange between the interior and exterior air of cold storage facilities, thereby lowering operating costs.

3. Other sectors: Application is also possible in building fields such as residential buildings and commercial complexes, meeting the special needs of different places.

Main parameters

| Item | Parameter |

| Material feeding width | 925~1220mm |

| Material thickness | 0.3~1.0mm |

| Uncoiler | Manual Uncoiler |

| Loading weight | 5ton |

| Forming speed | 8-15m/min |

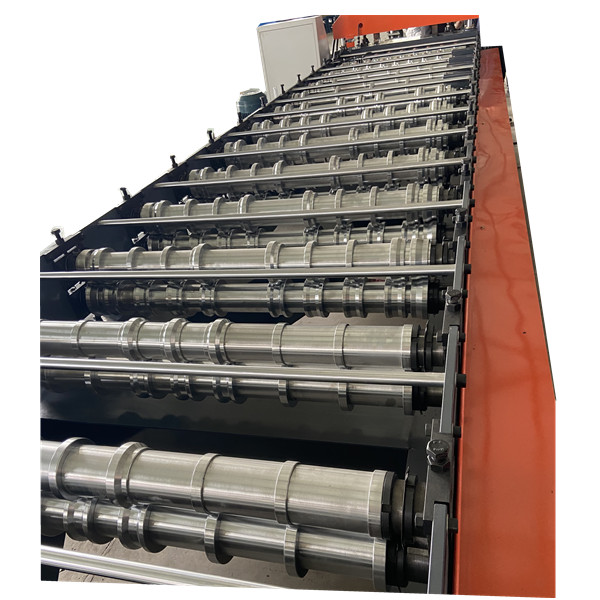

| Forming Steps | 16 stations |

| Shafts materials | 45# high quality steel |

| Shafts diameter | 70mm |

| Roller materials | 45# high quality steel, hard chrome coated 0.05mm |

| Transmission | Chains-sprockets |

| Main motor power | 11kw |

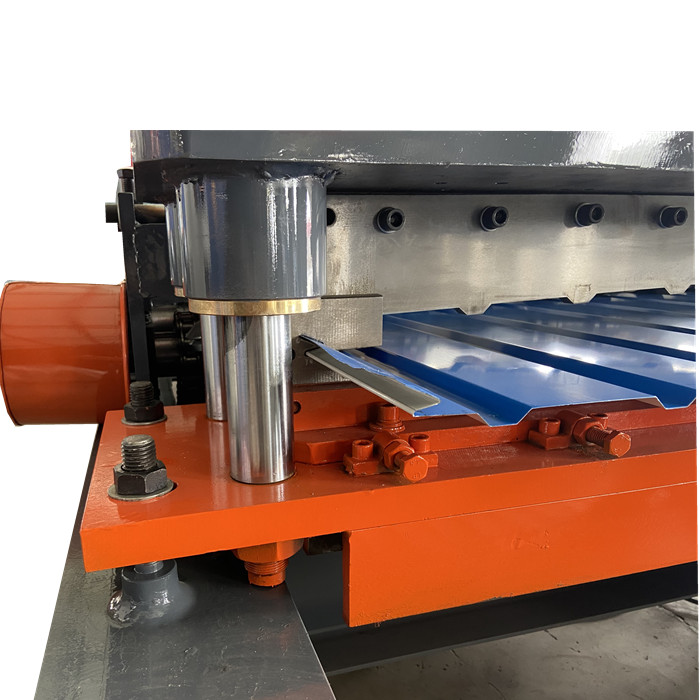

| Cutting blade | Cr12 with quenched treatment 60-62 |

| Hydraulic power | 5.5kw |

| Overall dimensions | 8600x1500x1300mm |

Recommended related machine