As an efficient roofing tile production equipment, double-layer roofing tile machine plays an important role in the field of building material manufacturing. It is able to produce two different types of roofing tiles at the same time, which greatly improves the production efficiency and reduces the production cost. The metal coil is fed into the forming machine through the feed introduction platform, where it is continuously rolled by a series of rollers and gradually pressed into the desired double-layer roof tile shape. During the rolling process, the PLC control system accurately controls the speed of the motor and the pressure of the hydraulic station according to the preset parameters to ensure the forming accuracy of the roof tile. When the roof tile is formed to a set length, the hydraulic shear device acts under the command of the PLC system to cut the roof tile and complete a production cycle. In the production process, the upper and lower production modes can also be quickly switched through the electric control cabinet or clutch to realize the production of different types of roof tiles.

Performance characteristics:

1.Efficient production:

It can produce two different types of roofing tiles at the same time, which greatly improves the production efficiency compared with the traditional single-layer roofing tile machine. For example, in the same time, the output of the double-layer roof tile machine can reach about twice that of the single-layer machine, which greatly shortens the production cycle and improves the production capacity and market competitiveness of the enterprise.

2.Space-saving:

Since one equipment has the production capacity of two tile types, compared with the purchase of two single-layer roof tile machines, the double-layer roof tile machine occupies a smaller area, generally only about 1/3 of the area of two single-layer roof machines. This can effectively save plant space and reduce site rental costs for production enterprises with limited space.

3.Flexible operation:

The equipment is equipped with an advanced electronic control system, which can quickly switch the upper and lower production modes through the electric control cabinet or clutch and other devices, which is convenient for users to flexibly adjust the production of tile types according to different order needs. Plate changes are also shorter, typically within a few minutes, further increasing the productivity and flexibility of the equipment.

4.High-precision molding:

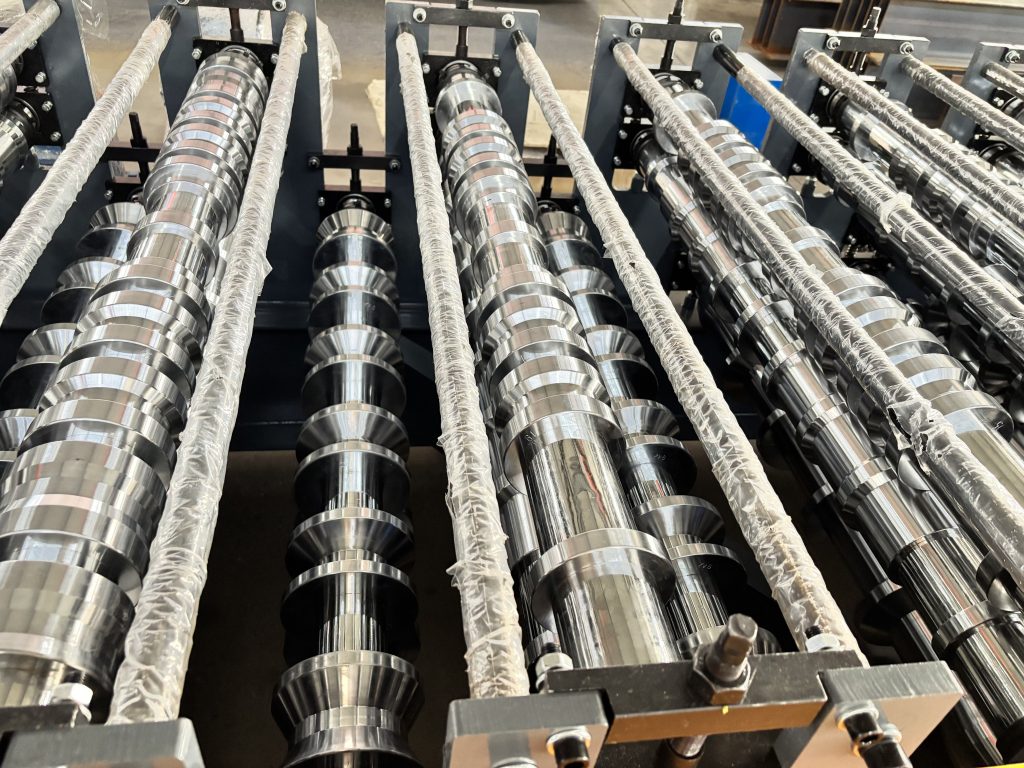

The use of advanced roll forming technology and high-precision mold design, with the precise control of the production process by the PLC control system, can ensure that the pressed roofing tile has high-precision size and good flatness. The key dimensional errors such as wave height and wave distance of roof tiles can be controlled within a very small range to meet the strict requirements of the construction industry for the quality of roof tiles.

5.Energy saving and environmental protection:

Some double-layer roof tile machines adopt energy-saving motors and advanced control systems, which can automatically adjust the motor speed according to the actual operating load of the equipment and reduce energy consumption. At the same time, the equipment has low noise, low vibration and less pollution to the environment during operation, which is in line with the development trend of modern industrial energy conservation and environmental protection.

6.Durable equipment:

Key components such as frames, forming shafts, rollers, shear blades, etc. are made of high-quality materials, and have undergone strict processing technology and heat treatment, with high strength, hardness and wear resistance. The equipment undergoes strict quality inspection and trial operation before leaving the factory to ensure that it can operate stably and reliably in a long-term high-intensity production environment, reduce the number of equipment failures and maintenance, and reduce the production cost of the enterprise.

Fields of application:

1.Industrial buildings:

It is widely used in various industrial buildings such as factory buildings, warehouses, and logistics centers. Double-layer roof tiles have good waterproofing, thermal insulation and thermal insulation properties, which can provide reliable roof protection for industrial buildings, and their high strength and durability can also meet the requirements of industrial production environments. For example, in a large-scale steel structure workshop, the use of double-layer roof tiles can effectively reduce the maintenance cost of the roof and improve the service life of the plant.

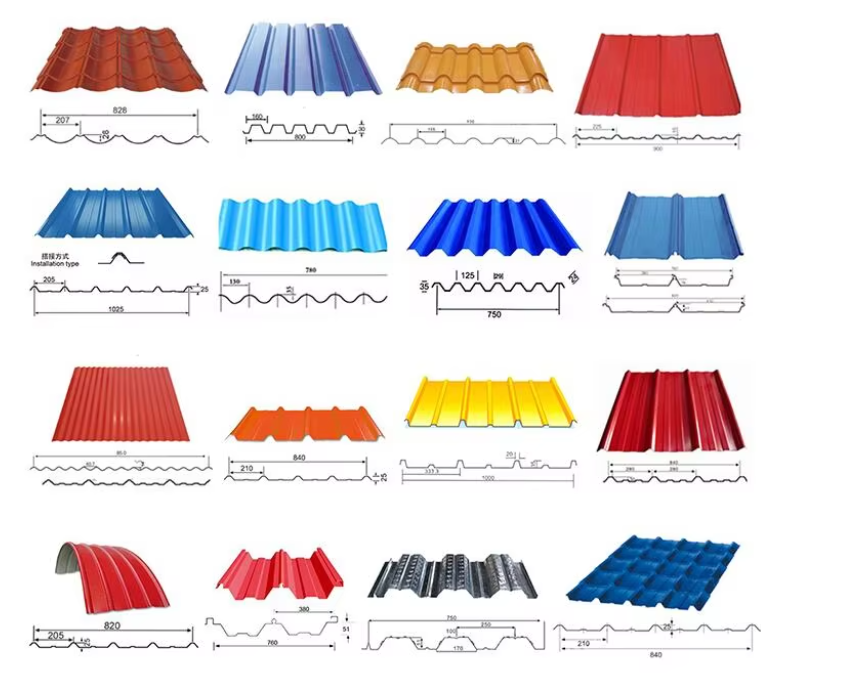

2.Civil buildings:

suitable for roofing projects of villas, residential quarters, apartments and other civil buildings. The rich colors and various tile types of double-layer roof tiles can add aesthetics to the building and enhance the overall image of the building. At the same time, its excellent performance can also provide residents with a comfortable and safe living environment, such as good waterproof performance can avoid damage to the interior caused by roof leakage.

3.Public buildings:

There are also a large number of applications in public buildings such as gymnasiums, exhibition halls, airport terminals, and stations. These buildings have high requirements for the performance and appearance of roofing materials, and the roofing tiles produced by double-layer roof tile machine can not only meet the requirements of large-span buildings for roof bearing capacity, but also create a magnificent and beautiful architectural effect through unique design and color matching, and improve the quality and image of public buildings.

4.Temporary construction:

Because the roofing tile produced by the double-layer roof tile machine has the characteristics of easy installation and low cost, it is also widely used in some temporary buildings such as construction site dormitories, prefabricated houses, etc. These temporary buildings are usually sensitive to the construction period and cost, and the double-layer roof tiles can be quickly erected, and can be easily dismantled and recycled after the end of use, which meets the needs of the use of temporary buildings.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI,GL

|

Thickness:0.3-0.8mm

Width:1000mm/1250mm(As per profile drawing)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16+18 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

10500*1600*1600(customize)

|

|||

|

Weight

|

11.5T

|

|||

|

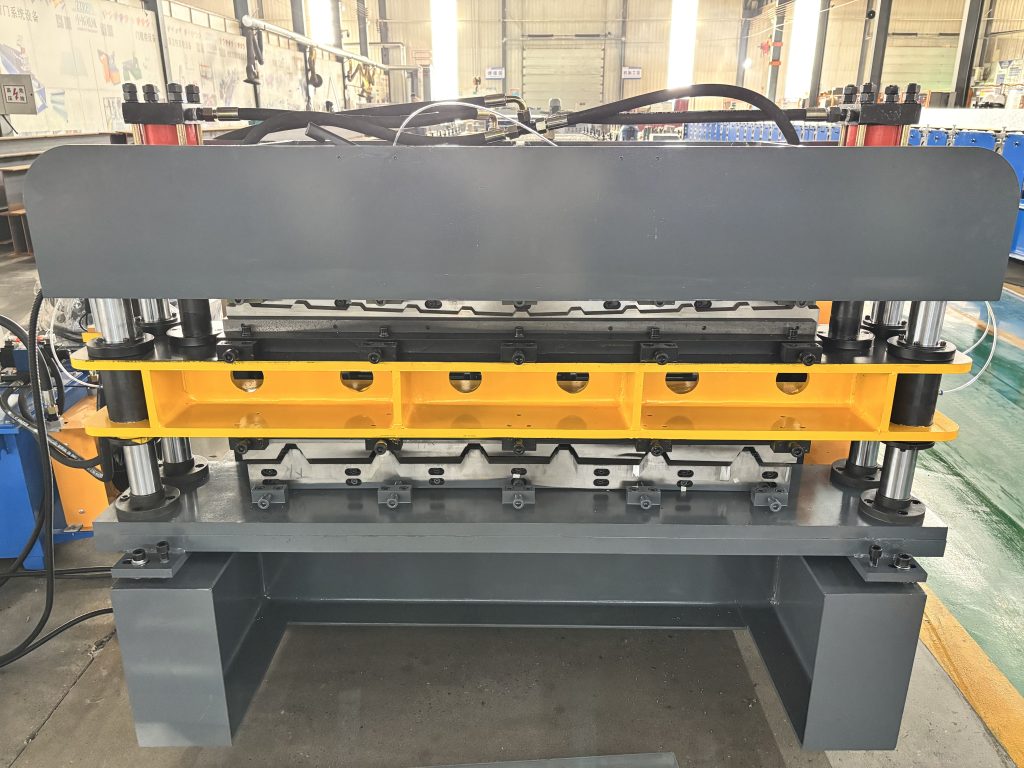

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||