Work flow of the machine

https://www.youtube.com/watch?v=sdtig-UrMDE&pp=0gcJCcEJAYcqIYzv

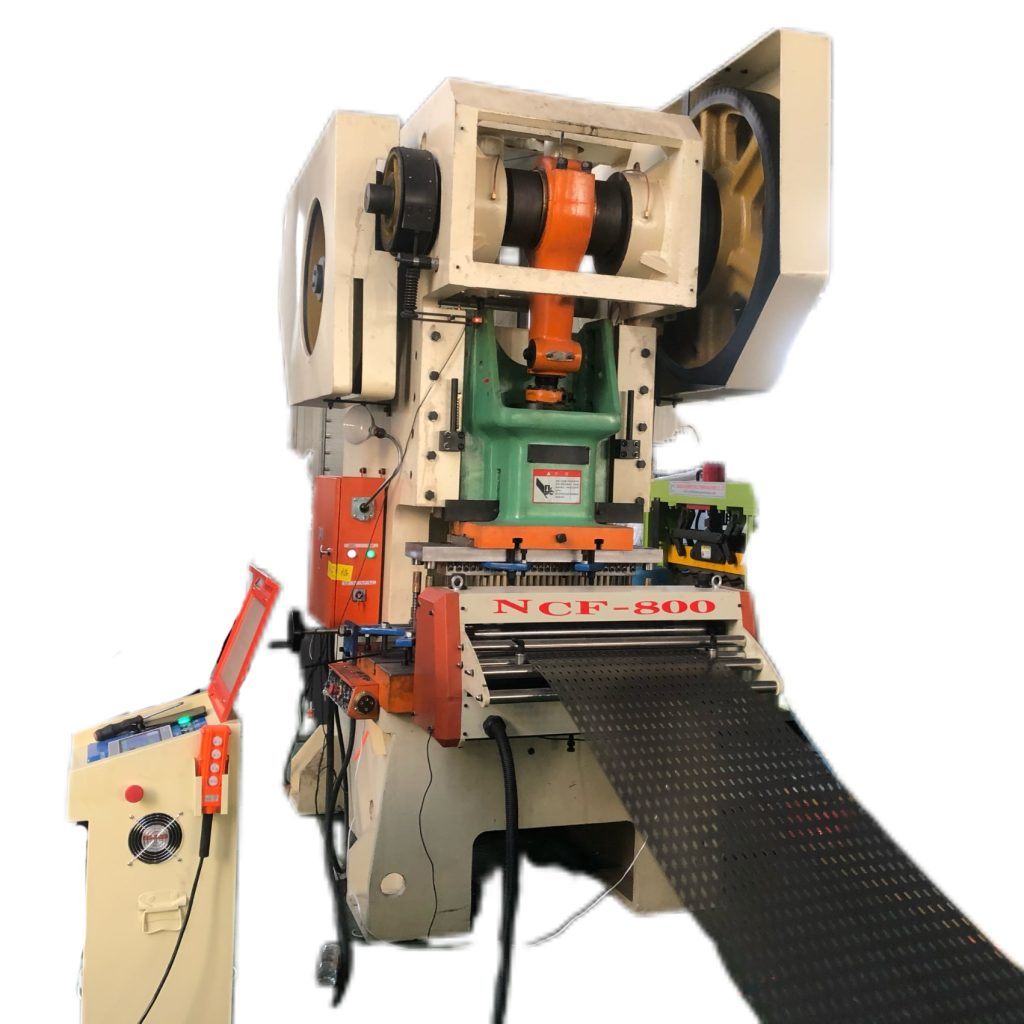

Customized Metal Steel Cable Tray Roll forming Machine

Features and advantages of cable tray cold forming machine

1. Enhanced Production Efficiency and Reduced Labor Dependence

Traditional cable tray manufacturing relies heavily on manual operations, which are not only inefficient but also prone to human errors that can compromise the final product. The introduction of cable tray forming machines has revolutionized this process by automating most production steps, significantly cutting down on manual labor requirements.

A single forming machine can replace multiple workers, drastically boosting overall productivity. What’s more, these machines are designed to be user-friendly—their operations are simple to learn and master, eliminating the need for highly skilled technicians.

This not only reduces a company’s labor costs but also streamlines workflow, enabling faster turnaround times for orders. By shortening delivery cycles, businesses can enhance their market responsiveness and gain a competitive edge in the industry.

2. Consistent Quality Assurance and Improved Uniformity

Manual cable tray production is inherently vulnerable to human factors, making it challenging to maintain consistent quality across each unit. Issues like inconsistent dimensions, weak welds, or uneven finishes are common, affecting both performance and reliability.

In contrast, modern cable tray forming machines are equipped with advanced automatic control systems that precisely regulate every stage of production, ensuring each tray meets strict dimensional accuracy and uniformity standards.

These machines also utilize high-quality raw materials, which undergo rigorous high-temperature heat treatment and surface processing to enhance structural strength and long-term stability. Automated cutting and welding functions further guarantee that each joint is secure and durable, making the final products more reliable in real-world applications.

3. Lower Scrap Rates and Cost Savings

Manual cable tray fabrication demands high technical proficiency, and even minor mistakes can lead to a high rate of defective products.

This not only wastes valuable materials but also drives up production costs significantly. Cable tray forming machines, however, minimize such inefficiencies through pre-programmed settings and automated controls, which execute each manufacturing step with precision. This reduces errors and scrap generation dramatically.

Additionally, these machines are capable of optimizing material usage by cutting and repurposing leftover scraps, further minimizing waste. Their continuous production mode eliminates the delays and interruptions typical in traditional manual processes, ensuring a steady workflow that maximizes output while keeping costs in check.

The main parameters of the machine

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

65mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

About 6T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

30m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Recommended related machine