Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.15- 0.5mm Width:914mm/1450mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

5T/10T/15T

|

||

|

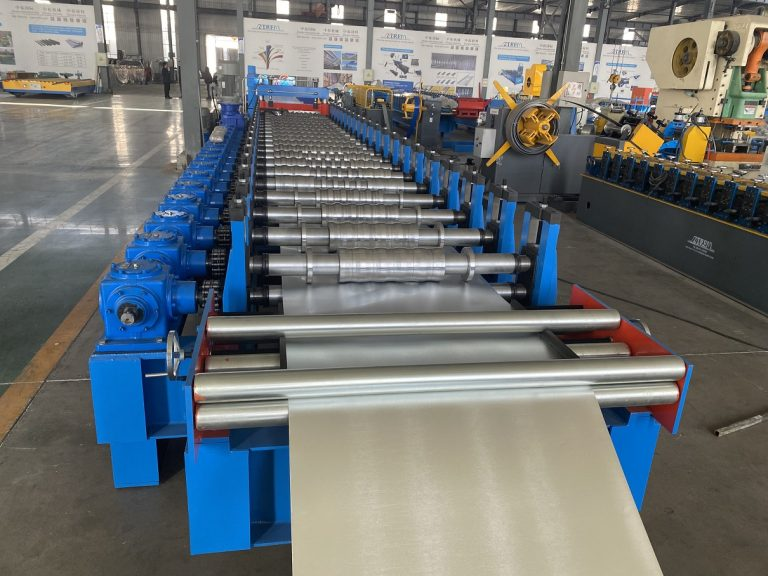

3.Main body

|

Roller station

|

20 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Gear box transmission

|

|||

|

Dimension(L*W*H)

|

10500*1650*1400 mm(customize)

|

|||

|

Weight

|

15T

|

|||

|

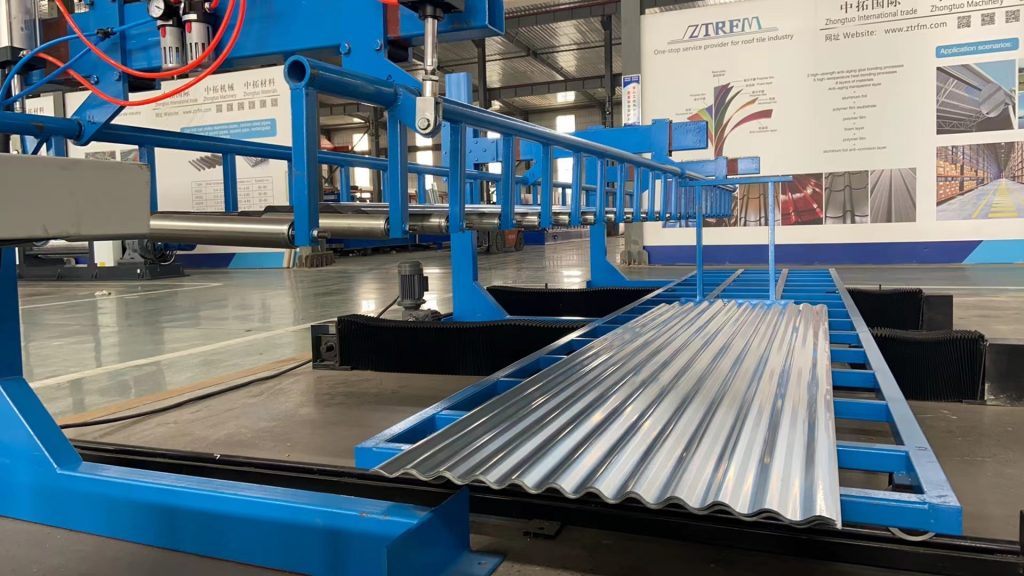

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

30-40 m/min

|

The speed is adjustable

|

||

Product Description:

In the field of building material production, high speed corrugated roof sheet roll forming machine have become indispensable equipment for many construction projects due to their unique functions and efficient production capacity. It is specifically used to produce roofing tiles with specific curvatures to meet the needs of roofing materials for various architectural styles. The following will introduce the high speed corrugated roof sheet roll forming machine in detail from the aspect of working principle.

1.First, the coil or sheet metal is placed on the unloading rack of the feeding system, and the material is introduced into the forming system through a guide.

2.In the forming system, the material passes through the individual forming rollers in turn, and the forming rollers roll the material step by step according to the preset shape and sequence. After each forming roller, the shape of the material is one step closer to the shape of the target arc roof tile, and after the continuous action of multiple forming rollers, the prototype of the roof tile with specific arc and wave pattern is finally formed.

3.After forming, the continuous plate enters the shearing system, and according to the length parameters set by the control system, the shearing system accurately cuts the plate to obtain pieces of independent arc roof tiles.

4.Under the unified scheduling of the control system, the whole production process works together to achieve automated and efficient production.

Machine advantages:

1.High production efficiency

(1)The application of servo tracking cutting technology enables the machine to cut extremely fast, up to 25 to 40 meters per minute, and can quickly complete the production of a large number of roof tiles under the continuous operation of the main molding machine, which can meet the needs of large-scale construction projects.

(2)High degree of automation, from feeding, forming to shearing, the whole process does not require a lot of manual intervention, only a few operators are required to monitor and maintain the equipment, reducing manual operation time and further improving production efficiency.

2.Stable product quality

(1)The shearing method of one side and one guide pillar and the design of high-precision forming roller ensure that the curvature and edge accuracy of each tile meet the strict design standards, and the dimensional error can be controlled within the range of millimeters, and the consistency of the product is good.

(2)The molding method of split molding, through a number of independent and collaborative module operations, the flatness and aesthetics of the tiles are specially optimized, so that the output tiles not only have uniform arc and small size error, but also have smooth surfaces and regular edges, which greatly improves product quality.

3. Significant cost-effectiveness

(1)Although the initial investment cost of the equipment may be slightly higher than that of some conventional brick machines, it can effectively reduce production costs in the long run through fast and precise positioning and efficient production speed, which reduces commissioning time and material waste during the production process.

(2)The core components of the equipment are manufactured with high-quality materials and advanced technology, such as the surface hardness and wear-resistance of the guide pillar, the forming roller is specially treated, and the lubrication system is good, which makes the service life of the equipment longer, reduces the frequency of equipment replacement and maintenance, and further reduces the cost of use.

4.Various product specifications

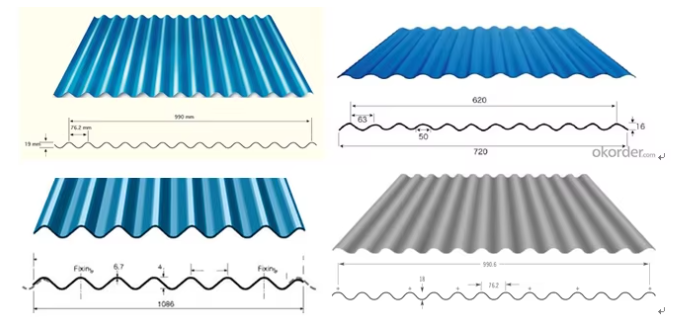

(1)The tiles produced have a wavewidth of about 63 mm, which is well adapted to the paving needs of various building roofs, whether it is a large area of flat slope roofs or curved dome structures, which can be arranged to achieve a tight fit and reduce installation gaps.

(2)The tile thickness can be flexibly adjusted from 0.3 mm to 0.8 mm to suit different building scenarios and needs. Thinner specifications are suitable for buildings that require weight and relatively low performance requirements such as waterproof and windproof, such as scenic pavilions and temporary roofs; The thicker specifications are suitable for buildings that need to withstand severe weather such as strong winds and heavy rains, such as houses and industrial plants in coastal areas.

Application scenarios:

1.Restoration and new construction of classical buildings:

In some restoration projects of antique buildings or historical buildings, the tiles produced by the high speed corrugated roof sheet roll forming machine can accurately restore the curvature and style of traditional roof tiles, adding a simple and elegant atmosphere to the building. For example, in some ancient city restoration projects, the tiles produced by this machine can not only meet the historical requirements of the building’s appearance, but also have the durability and waterproof performance of modern materials.

2.Modern villas and high-end residences:

Modern villas and high-end residences pay attention to the uniqueness and aesthetics of the architectural appearance, and the elegant arc of the corrugated roof tile can create a unique visual effect for the building and enhance the overall quality of the building. Its good waterproof and windproof performance can also provide reliable protection for the residence and meet the needs of the owners for a high-quality living environment.

3.Commercial buildings and public facilities:

such as shopping malls, hotels, exhibition halls, gymnasiums and other commercial buildings and public facilities, the use of arc roof tiles can create a distinctive and modern architectural appearance, attracting people’s attention. At the same time, its efficient production capacity can also meet the demand for the number of roof tiles in these large-scale construction projects, ensuring the progress of the project.

4.Scenic buildings and characteristic towns:

In the construction of buildings and characteristic towns in the scenic area, the tiles produced by the high speed corrugated roof sheet roll forming machine can be integrated with the surrounding natural environment and cultural atmosphere to create an architectural landscape with regional characteristics and cultural connotations, adding unique charm to the scenic spots and characteristic towns.

Products Display: