Here is the C Channel working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

0-70m/min(customized)

|

The speed is adjustable

|

||

Product Description:

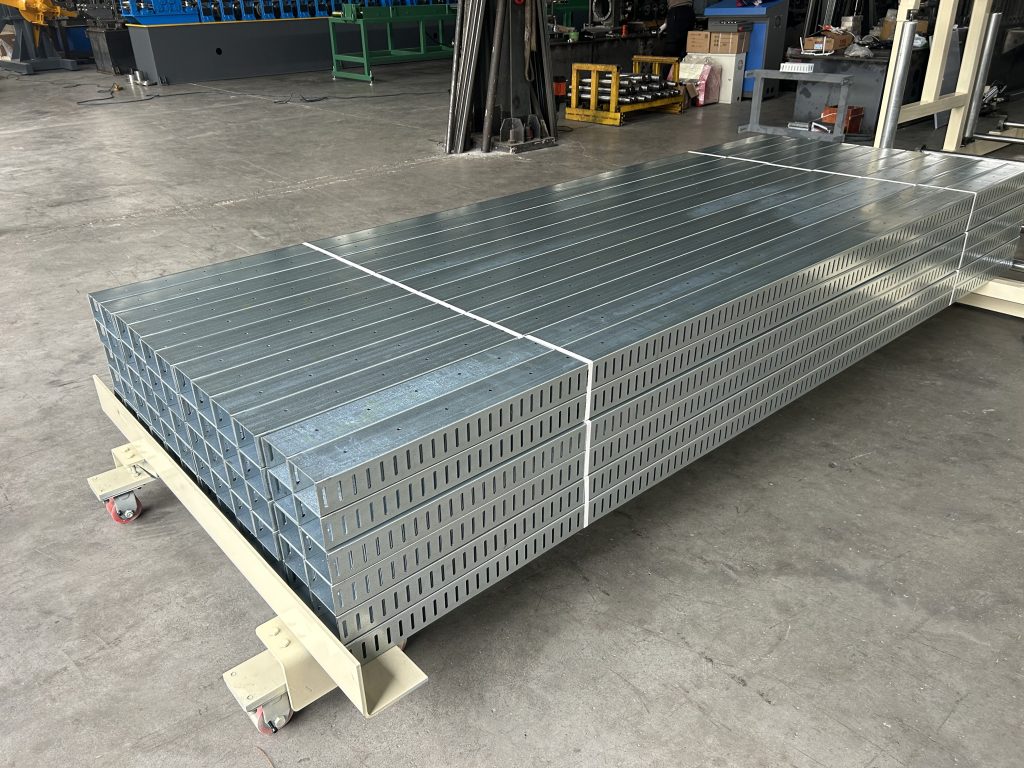

The C Channel Steel Profile Drywall Track Stud Light Steel Framing Roll Forming Machine is a specialized equipment for producing metal section profiles through cold rolling forming process, mainly used in the manufacturing of non load bearing partition wall systems and ceiling keel frames in the construction field. This equipment uses strip steel as raw material and forms complex cross-section keel profiles such as C-Channel, U-Channel, T-Channel, and L-Channel through continuous cold rolling. It is widely used in the production of light steel keels, painted keels, card keels, and other products.

The profiles produced by the C Channel Steel Profile Drywall Track Stud Light Steel Framing Roll Forming Machine are widely used in the construction industry, mainly for the vertical keel frames of non load bearing partition wall systems and the main keels of ceiling keel frames. C Channel is used as a vertical keel frame to support the partition wall system, ensuring the stability and safety of the wall; The T-shaped keel serves as the main keel in the ceiling keel frame, used to connect the ceiling skeleton with the four interior walls or column walls.

Main advantages:

1.Easy installation:

The design of the C-Channel partition keel machine makes the installation process very simple, even novice decorators can easily get started. Its lightweight design makes the handling and installation process easier.

2.Wide applicability:

C-Channel partition keel is suitable for occasions that require strong support, such as heavy-duty partitions or high ceilings. Its unique cross-sectional design ensures optimal applicability in different scenarios.

3.Reliable quality:

The C-Channel partition keel is made of high-quality steel and has undergone strict quality testing, which can withstand long-term use without deformation. Its surface has undergone special treatment to prevent corrosion and rust, and it can maintain a long service life even in humid environments.

4.High construction efficiency:

Due to the use of prefabricated construction methods, the construction efficiency of the C-Channel partition keel machine is relatively high, and the general construction technology level can complete 3-4 square meters of partitions per working day.

5.Structural safety and reliability:

The C-Channel partition keel has high strength and stiffness, making the structure safe and reliable. For example, when using a partition keel with a width of 50-150mm to make a 3.25-6.00-meter-high partition, under a uniformly distributed load of 250 N/m ², the deflection value of the partition keel can meet the standard requirement of not exceeding 1/20 of the height.

6.High cost-effectiveness:

The use of C-Channel partition keel machine can greatly shorten construction time and reduce construction costs. At the same time, its excellent fire prevention, moisture resistance, corrosion resistance and other characteristics also reduce maintenance costs in the later stage.

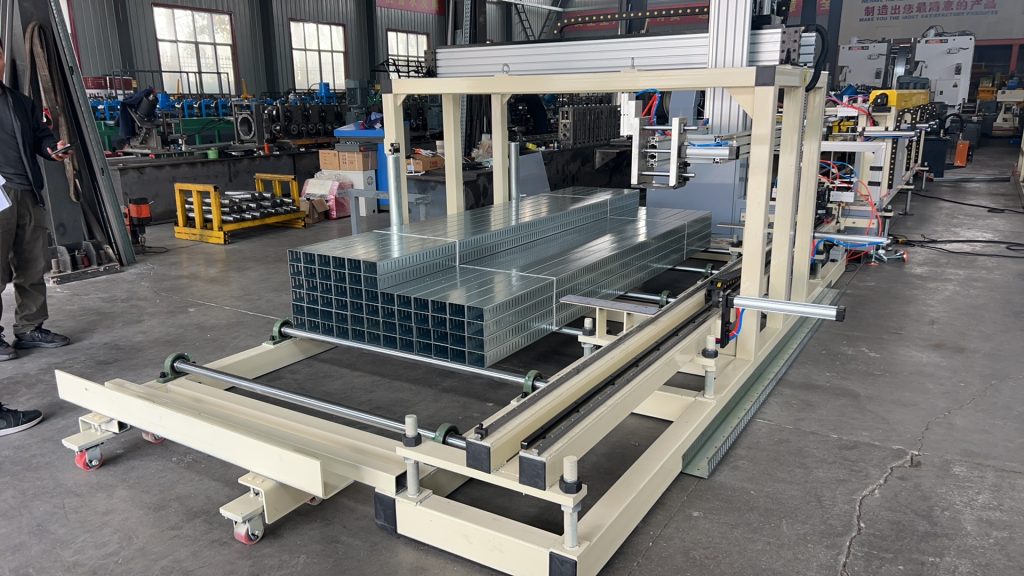

This machine is equipped with an automatic palletizing device:

- Improve production efficiency:

The palletizer can work continuously 24 hours a day, with fast palletizing speed, which can significantly improve production efficiency. Through automated operations, production delays and errors caused by human factors have been reduced, ensuring the continuous and stable operation of the production line. - Reduce labor costs:

Using a palletizer can reduce labor costs. Automated operations reduce the palletizing process that requires a significant amount of manpower and lower labor costs. In addition, the operation process of the palletizer is precise and fast, which can greatly improve production efficiency and reduce the cost per unit of product. - Ensure product quality:

The palletizer has high-precision positioning and gripping capabilities, which can ensure that the goods are neatly and stably stacked, reduce product damage during transportation, and thus ensure product quality. - Strong adaptability:

By replacing the gripper and adjusting the program, the palletizer can adapt to goods of different shapes, sizes, and weights. This flexibility enables it to adapt to various production environments and requirements, providing great convenience for enterprises. - Reduce product damage:

During manual stacking, product damage can easily occur due to improper operation, fatigue, and other reasons. The palletizer adopts advanced control systems and mechanical structures, which can accurately control the stacking position and height, avoiding product damage.