Work flow of Cut to Length Line

https://www.youtube.com/watch?v=z62jSgT6COo

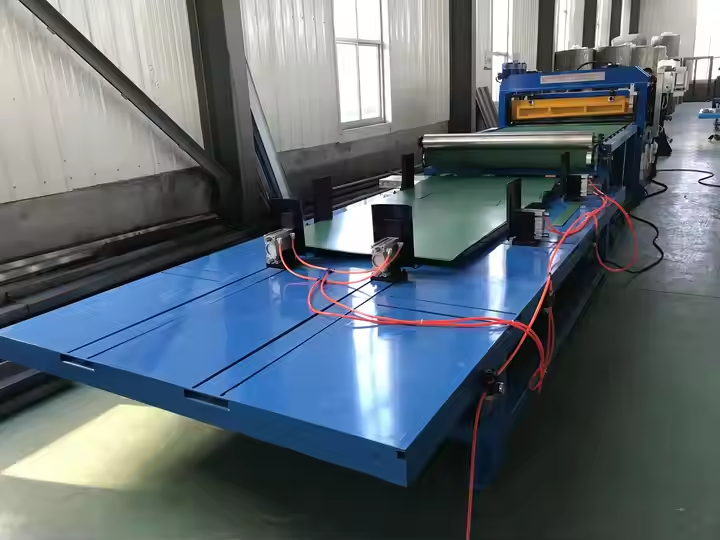

Introduction of cut to length line equipment

Cut to length machines, a type of metal shearing equipment, are extensively utilized across the manufacturing industry. Capable of precisely cutting a diverse range of metallic materials, including steel, aluminum alloys, and brass, these machines are characterized by their high efficiency, accuracy, and reliability. As a result, they have become indispensable in sectors such as automotive, marine, aerospace, and general mechanical manufacturing.

Functionally, cut to length machines operate on the principle of applying shear force to cut metal materials. Comprising key components such as the shearing tool holder, shearing tool base, and cutting edges, the process initiates when the metal material is positioned on the tool holder. Subsequently, the tool base descends, bringing the cutting edges into contact with the workpiece, after which the metal is severed along the designated cutting lines. Through repetitive cycles of this operation, the metal material is transformed into pieces of the desired dimensions and shapes.

These machines offer a plethora of features and advantages. Firstly, their hydraulic or mechanical drive systems ensure stable and consistent shear force application, enabling seamless and highly accurate metal cutting operations, thereby enhancing overall productivity. Secondly, the integration of advanced control systems facilitates automated operation, significantly streamlining production processes. Additionally, the compact design of cut – to – length machines allows for efficient space utilization, making them adaptable to various manufacturing environments. Moreover, their rapid cutting speeds, low energy consumption, and minimal noise generation contribute to substantial cost savings for enterprises, effectively boosting their competitive edge in the market.

The application of cut – to – length machines is particularly prominent in the automotive industry. Given the extensive use of metal materials in automotive manufacturing for component fabrication and assembly, these machines play a pivotal role. They are capable of swiftly and accurately cutting metal materials for various parts, including vehicle bodies, doors, and chassis components. By precisely adhering to design specifications, cut – to – length machines ensure that automotive parts meet strict dimensional and shape requirements, thus safeguarding vehicle quality and safety.

Beyond the automotive sector, cut – to – length machines are also widely employed in marine, aerospace, and mechanical manufacturing industries. In shipbuilding, they are utilized to cut steel plates and aluminum alloys for constructing hull structures and components. In aerospace manufacturing, they facilitate the cutting of metal sheets and tubes for the fabrication of aircraft wings, fuselages, and other critical parts. Similarly, in mechanical manufacturing, they serve to cut diverse metal materials for the production of machine tools, tools, and other mechanical products.

Proper operation and maintenance of cut – to – length machines are crucial. Operators must be thoroughly familiar with the equipment’s operating procedures and safety protocols to prevent accidents. Regular inspections and maintenance routines are essential to maintain optimal machine performance. Special attention should be paid to frequently replaced components, such as tool holders, tool bases, and cutting edges, to uphold cutting quality and efficiency. Additionally, consistent cleaning and lubrication, along with timely replacement of lubricants, are necessary to minimize wear and tear caused by friction, thereby extending the machine’s service life.

In summary, cut – to – length machines stand as highly efficient, accurate, and reliable metal shearing solutions, playing an integral role in multiple manufacturing sectors. Through correct operation and systematic maintenance, these machines not only enhance production efficiency but also contribute to significant cost reduction, thereby providing essential support for enterprises seeking to enhance their operational capabilities and market competitiveness.

Technical parameter:

(1) Outer diameter of coil: maxF1600mm

(2) Inner diameter of coil: F508mm

(3) Maximum working speed: 60m/min

(4) Equipped with anti-releasing pressure arm: 1 pc

(5) Reel expansion and contraction range: F470~F530mm

(6) Spindle diameter: Φ232mm

(7) Effective length of reel: 1650mm

(8) Drive motor: 7.5KW

Leveling and slittingmachine : 1 set

Hydraulic shearing system : 1 set

Hydraulic station : 2 sets

PLC Control system : 1 set

Recommend related machine