Sandwich Panel Roll Forming Machine

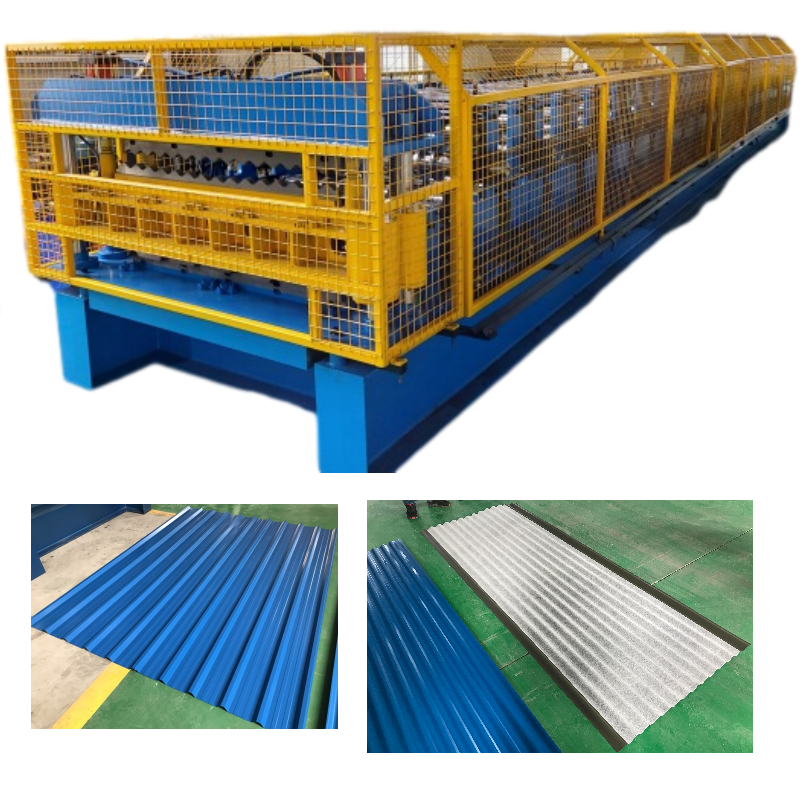

Sandwich Panel Roll Forming Machine is used to produce the roll forming machine for Sandwich panel which will work with sandwich panel production line.

Compare to normal Roof panel roll forming machine, this sandwhich panel need to be produced in the machine by opposite direction.

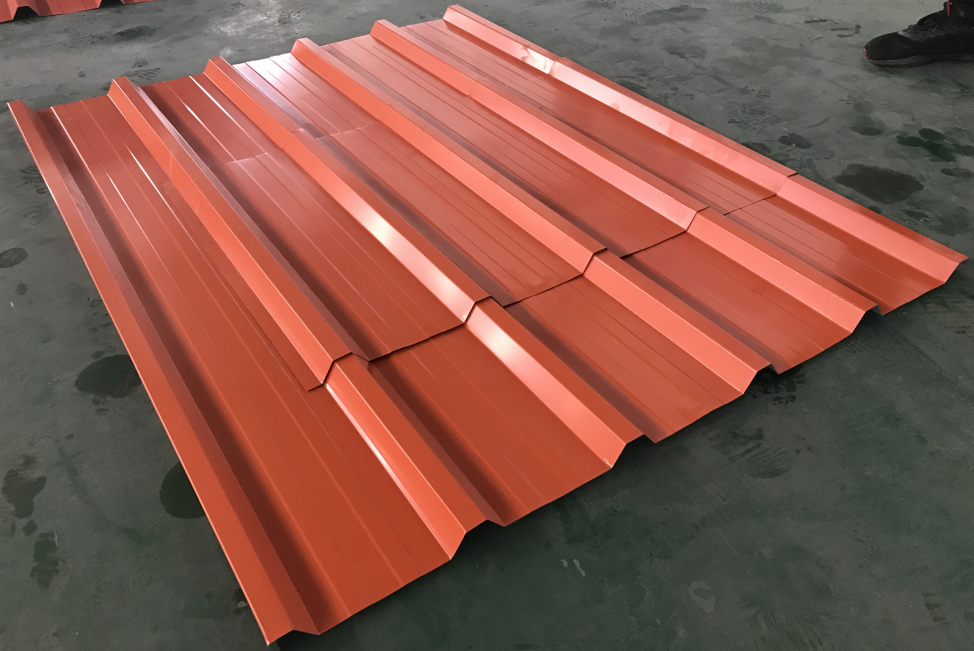

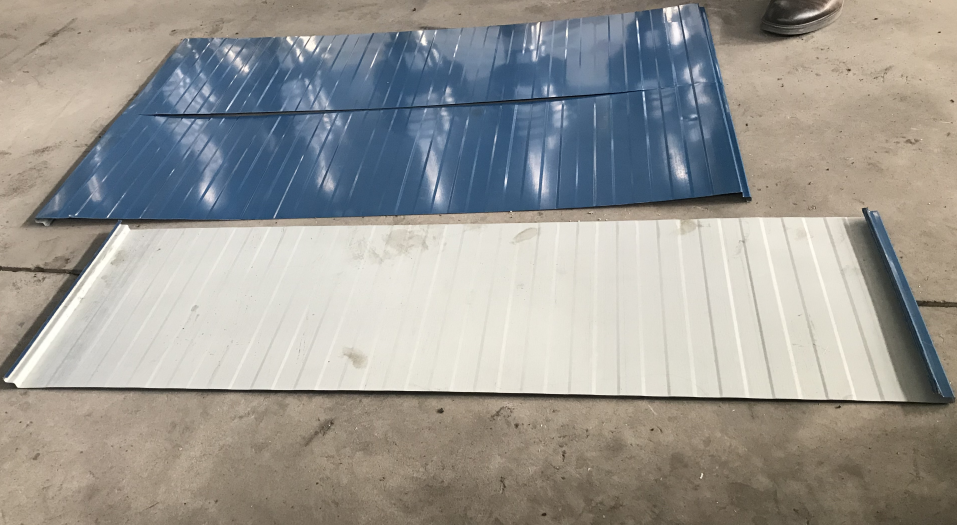

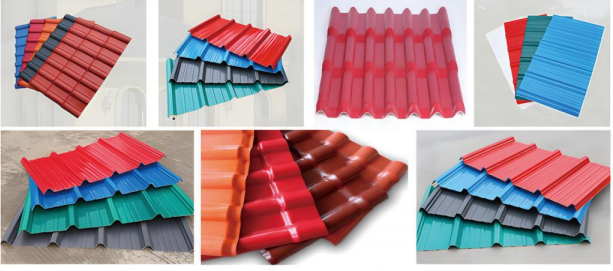

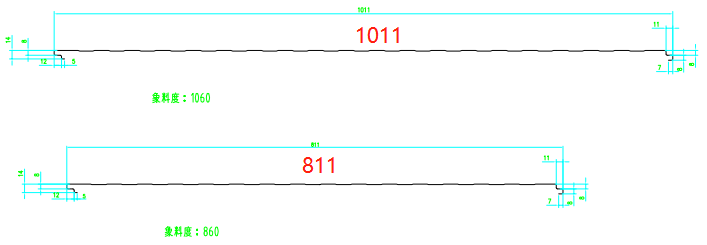

The profile drawing and picture of the sandwich panel:

The features of the Sandwich Panel Roll Forming machines: One machine can produce two different sizes.

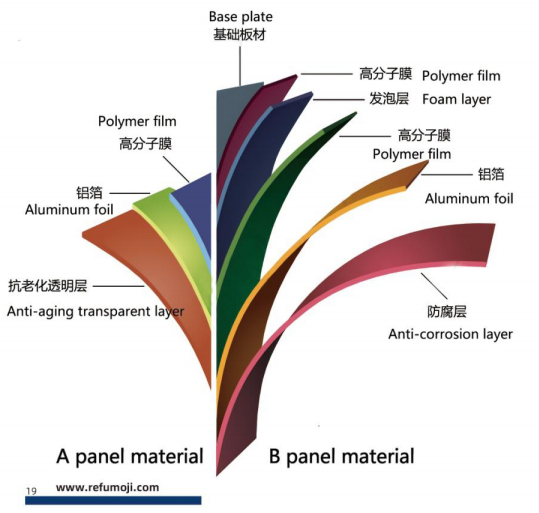

This machine also can produce our new filmed material which can replace the sandwich panel but the cost is much lower,here are the function introduction of our new filmed material:

- Anti-corrosion

- Anti-rust

- Anti-fire

- Color will not fade away within 30 years

- Sound insulation,heat insulation

- No glue,environmental friendly

The introduction for the component of our new filmed roofing material:

The components of the Sandwich Panel Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the machine:

| Item | Name | Specifications |

| 1 | Raw material | Galvanized steel and Pre-painted steel |

| 2 | Raw material thickness | 0.3-0.6mm(thickness range shouldn’t be too big) |

| 3 | Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

| 4 | Roller station | 13 stations for Sandwich bottom panel

24 stations for Sandwich up panel |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Shaft material | 45# steel with tempered |

| 8 | Transmission | by chain |

| 9 | Motor power | 5.5kw |

| 10 | Machine frame | 350H steel welded |

| 11 | Cutting type | Hydraulic cutting |

| 12 | Hydraulic power | 5.5kw |

| 13 | Cutting blade material | Cr12 with quenched treatment |

| 14 | Cutting tolerance | +/-1mm |

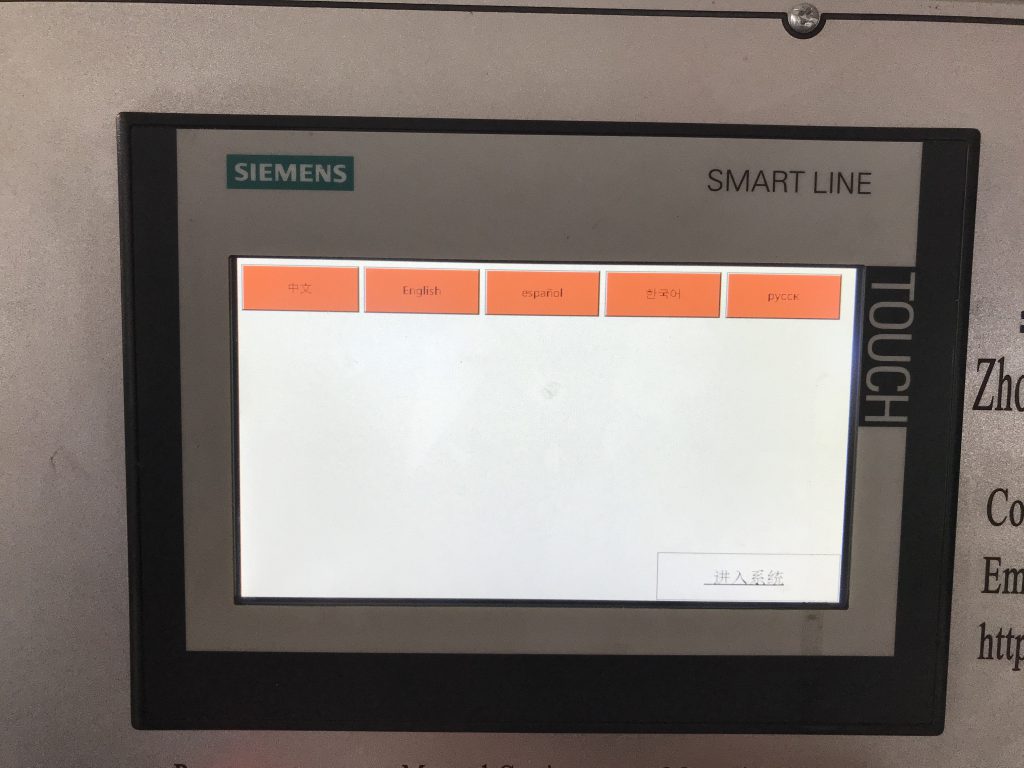

| 15 | Control system | PLC |

| 16 | Brand | PLC:Delta/Siemens/Mitsubishi

Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |

The features of our Sandwich panel roll forming machine:

- Decoiler: Manual one or hydraulic one for option,different budge can choose different type.

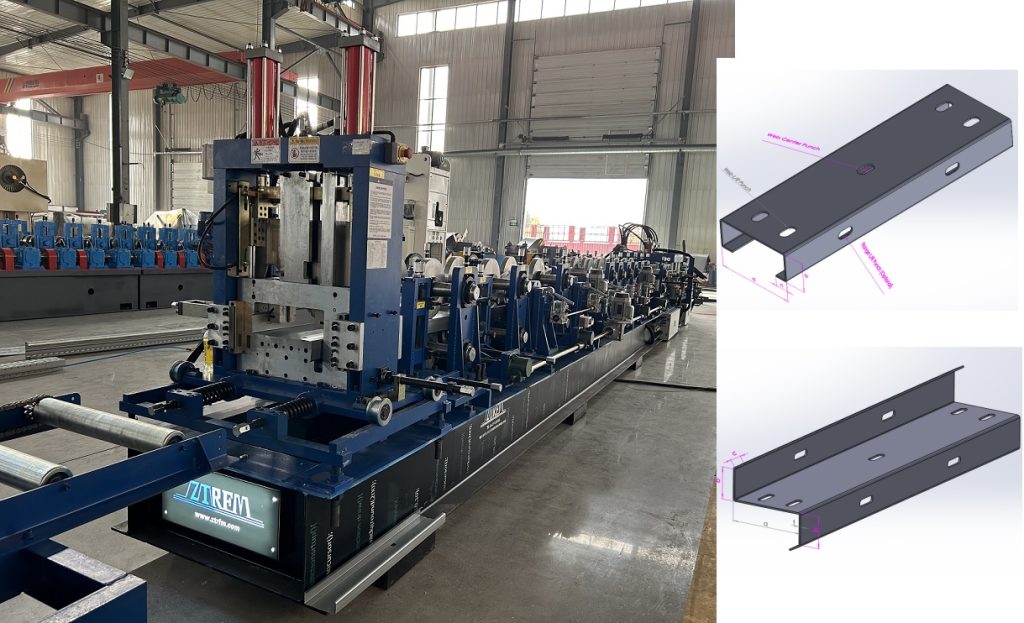

2. Roll forming machine:

- Machine frame:350# H steel welded,with beam supporter in the middle of frame

- Transmission:Double chains

- Shaft diameter:80mm,all the shaft are guaranteed solid

- Roller material:High grade 45# steel,the surface is chromed to improve the hardness of the roller

- Our double layer machine has the clutch device,with this device the machine’s upper layer and lower layer will not work at the same time,which can reduce the roller abrasion,so the machine’s life time will be longer too.

- We add the slitting blade in the machine to slit the extra material if the coil is too wide.

- Cutter:We use 4 pillars strong cutter frame,and the cutting mould is Cr12 mov with quenched treatment which can guarantee the quality

- Control system:Our control system use famous brand,such as Delt,Siemens,Omron, Schneider and Mitsubishi,and we also use the brand that customer want.

- Hydraulic system:All of our hydraulic stations are equipped with fan cooling,which can cool down the coil’s temperature after long time working or the working at hot weather.

Similar Roll Forming Machine: