Today, with the deep integration of architectural industrialization and green building concepts, exterior wall cladding has become the core exterior wall enclosure material for various types of buildings such as residential, commercial complexes, industrial plants, etc., relying on multiple advantages such as thermal insulation, fire and moisture prevention, and decorative aesthetics. The quality accuracy, production efficiency, and cost control of exterior wall cladding depend on the hard power of the processing equipment. Industrial Aluminum Wall Siding Panel Making Machine is not only a “bridge” connecting raw materials and finished products, but also a “core engine” for enterprises to seize market opportunities and achieve cost reduction and efficiency improvement, injecting new vitality of efficiency, precision, and environmental protection into building exterior wall engineering.

From residential buildings to commercial landmarks, from industrial plants to municipal infrastructure, Industrial Aluminum Wall Cladding Panel Making Machine empower various industries with precision and quality, and use technological innovation to solve efficiency, quality, and cost problems in the production of building materials. Choosing a high-quality Industrial Aluminum Wall Cladding Panel Making Machine is not only about choosing efficiency and precision, but also about choosing a long-term stable production guarantee and industry competitiveness. We take years of industry technology accumulation as the cornerstone, focus on the development needs of construction industrialization, provide one-stop services from equipment customization, installation and commissioning to after-sales maintenance, so that each equipment can accurately match the production needs of enterprises, help enterprises seize the opportunity in the wave of green buildings, and jointly build a new future of high-quality development in the construction industry!

The core features include:

1.High degree of automation:

The dual drive roller extrusion, sizing, laying, compounding, and re pressing processes are completed in one go, achieving industrial assembly line operations and significantly reducing manual labor intensity.

2.Lightweight and high-strength:

The unit area mass is only 1/10 of that of traditional red brick walls, with good seismic performance and a bending load resistance of over 5640N.

3.Thermal insulation:

With a high thermal resistance value (such as a 90mm thick plate with a thermal resistance of ≥ 1.35 (m ² · K)/W), it can effectively improve the energy-saving effect of buildings.

4.Fire and Waterproof:

It has excellent fire and waterproof performance and is suitable for various climatic environments.

5.Adjustable specifications and strong adaptability:

The equipment can produce boards of different thicknesses and lengths to meet the needs of different construction projects.

Application scenario:

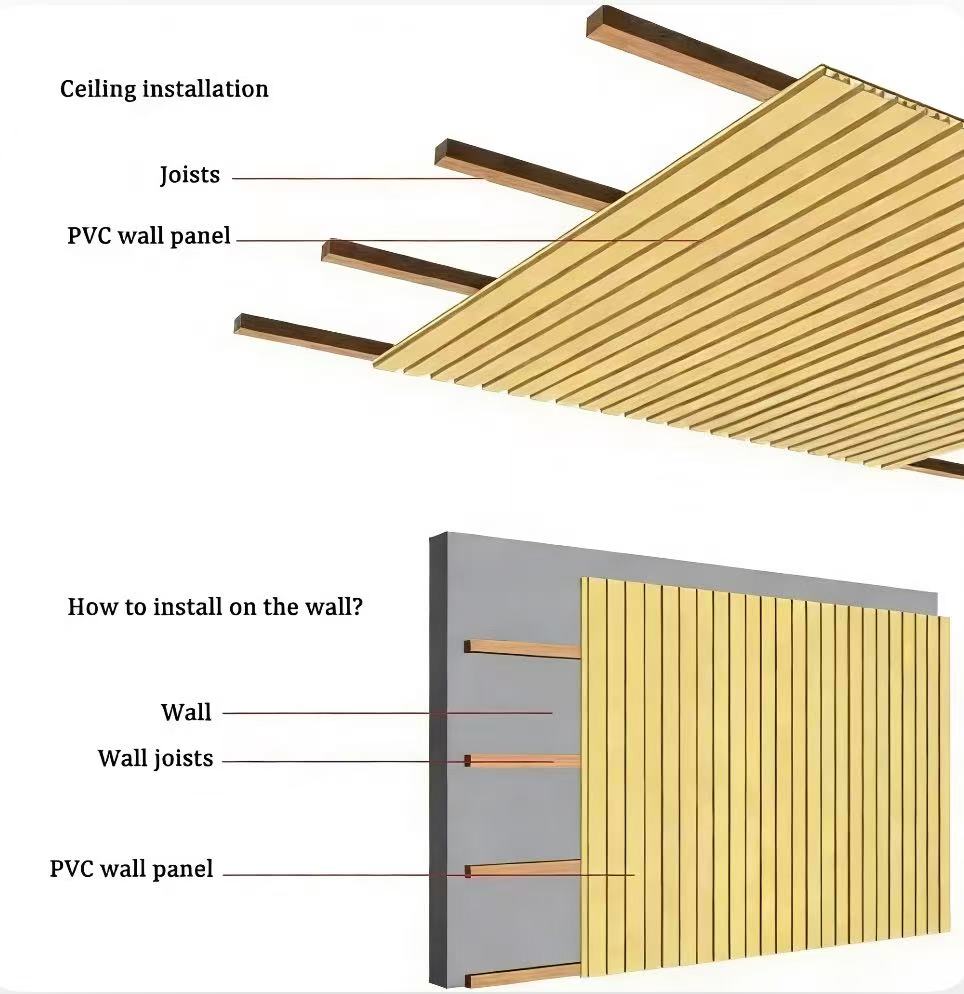

• Building exterior wall insulation system:

suitable for various building systems such as reinforced concrete walls, ceramic hollow block walls, steel structures, etc.

• Roof and ground insulation:

can be used for scenarios such as steel plate roofs, square floors, airport runway foundations, etc.

• Special fields:

places with high requirements for insulation and lightweight, such as refrigerated trucks, cold storage, industrial plants, etc.

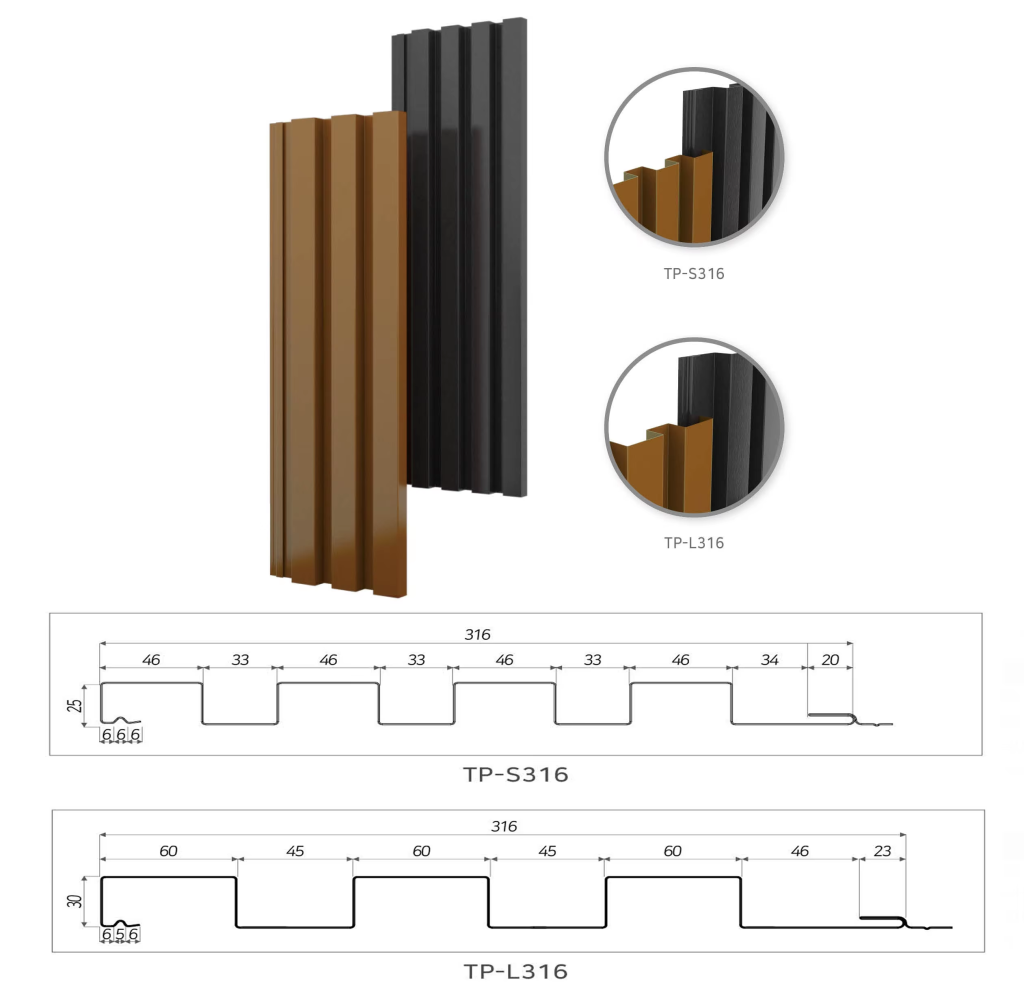

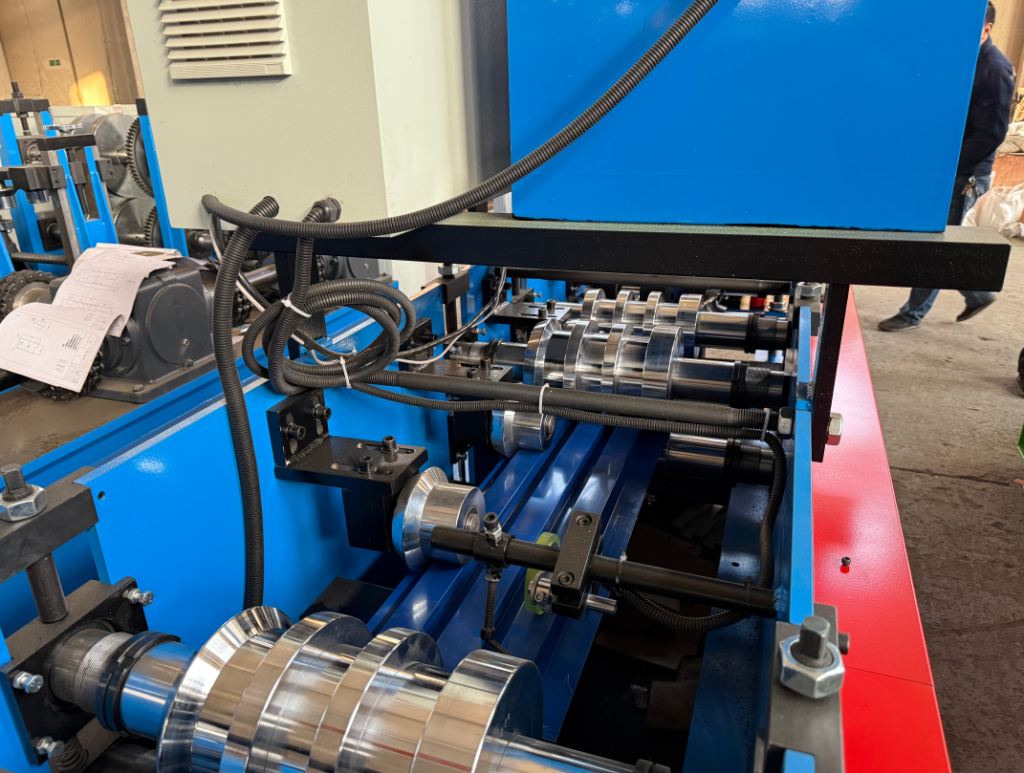

Pattern diagram:

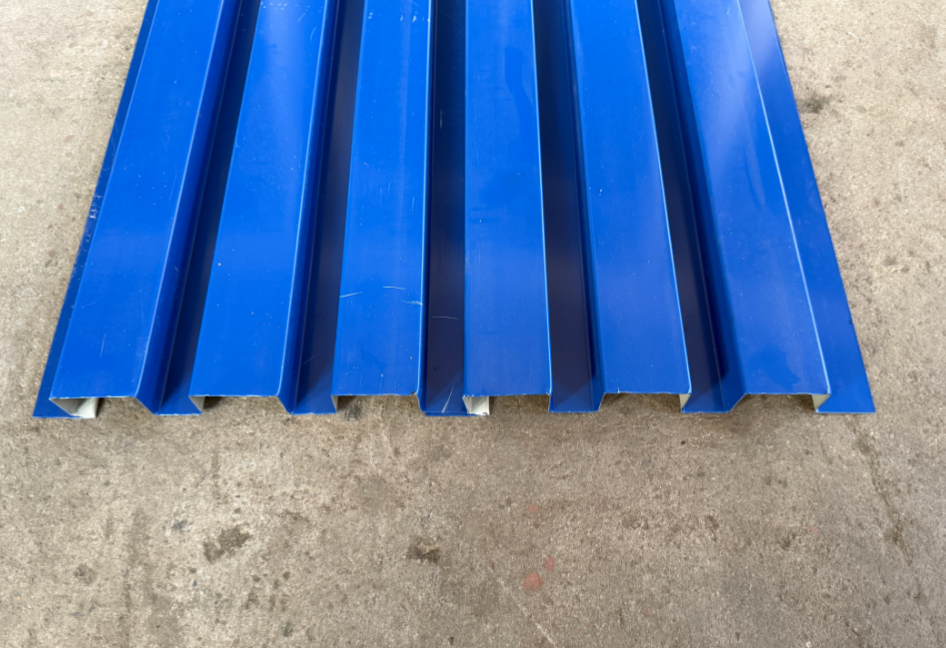

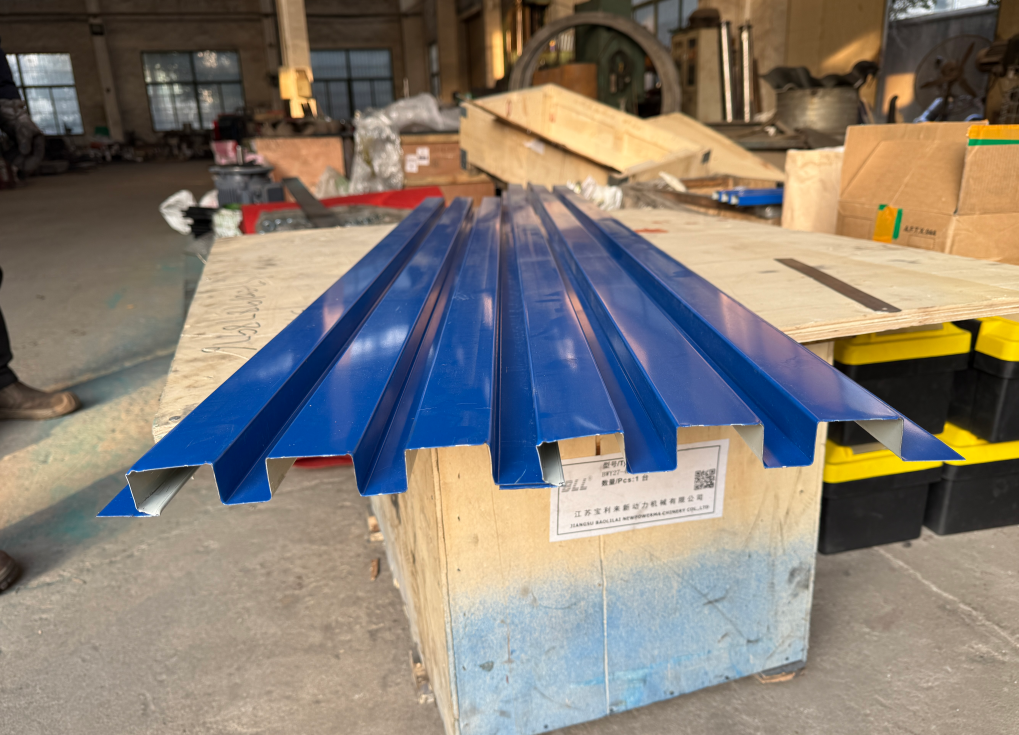

Finished product image:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-0.8mm

|

||

|

2.Decoiler

|

Hydraulic decoiler

|

Manual decoiler(will give you as free)

|

||

|

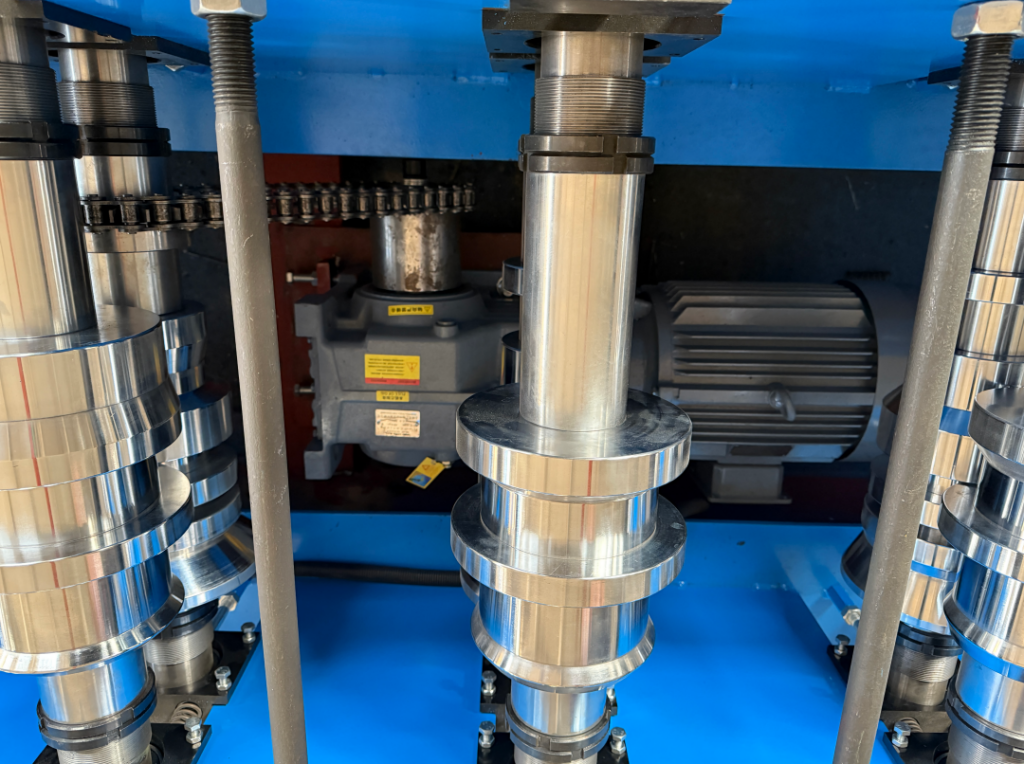

3.Main body

|

Roller station

|

28 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600mm

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||