https://www.youtube.com/watch?v=823tvlqRb4M

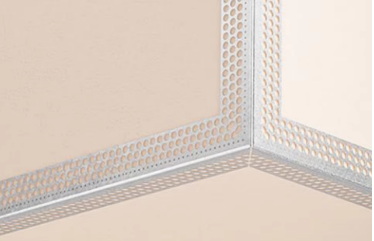

Perforated Wall Angle Steel Corner Bead Roll Forming Machine

The angle steel punching machine plays a vital role in the industrial sector with extensive applications. During operation, it features simple handling, low energy consumption, and minimal maintenance costs, effectively saving input costs. It serves as an ideal equipment for metal processing in modern manufacturing.

Below is an introduction to the product characteristics of the angle steel punching machine.

1. It boasts a wide application scope and a user-friendly operation method, facilitating convenient use for operators.

2. The equipment adopts excellent processing technology. The entire frame is welded integrally and subjected to high-temperature quenching treatment, endowing it with high rigidity and strength. Through vacuum high-temperature processing, its service life can be prolonged.

3. The angle steel punching machine utilizes mechanical crankshaft transmission, featuring a reasonable overall structure, light weight, low noise, simple and reliable performance, and overload protection function.

4. Before leaving the factory, the manufacturer has completed the debugging of the equipment.

Therefore, no horizontal adjustment is required upon use—it can be put into operation immediately after placement. Additionally, a foot tower control system can be optionally configured to enhance the automation of hole punching and shearing efficiency.

Product Parameters

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.3-0.8mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

18 rows(As your requirement)

|

||

|

Diameter of shaft

|

40mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

4500*600*1600(customize)

|

|||

|

Weight

|

3.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

3KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Application of Angle Steel

Perforated angle steel is widely applied in various fields. It not only serves for constructing various frame structures like beams and columns in buildings, but also acts as a decorative material to showcase unique aesthetic appeal in residential and commercial spaces — the punching process creates a distinctive design-oriented effect on the angle steel’s surface.

Furthermore, in shelf manufacturing, angle iron with double-sided punching can be formed into columns to hang shelf panels, supporting the load-bearing structure of the shelves. In the industrial sector, perforated angle steel is indispensable for hole processing in stainless steel security nets, guardrails, shelves, handrails, etc.

With its diverse functionality and practicality, it has become a crucial component in numerous scenarios.