Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.8-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

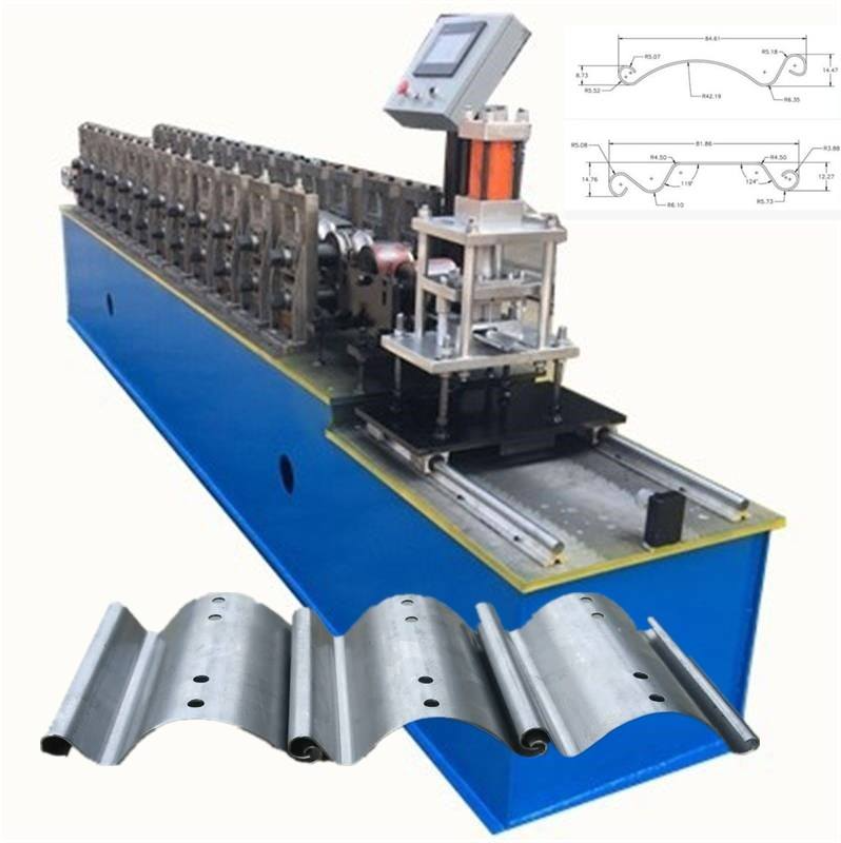

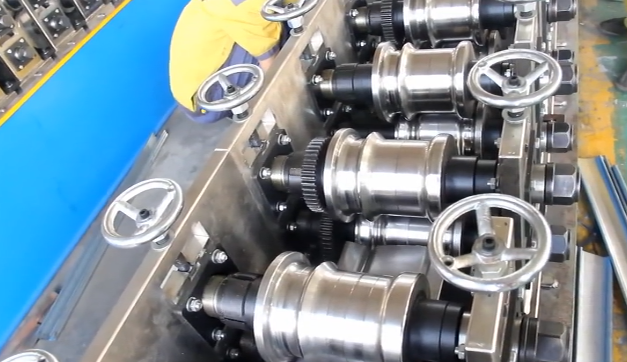

Roller station

|

14rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 5T

|

|||

|

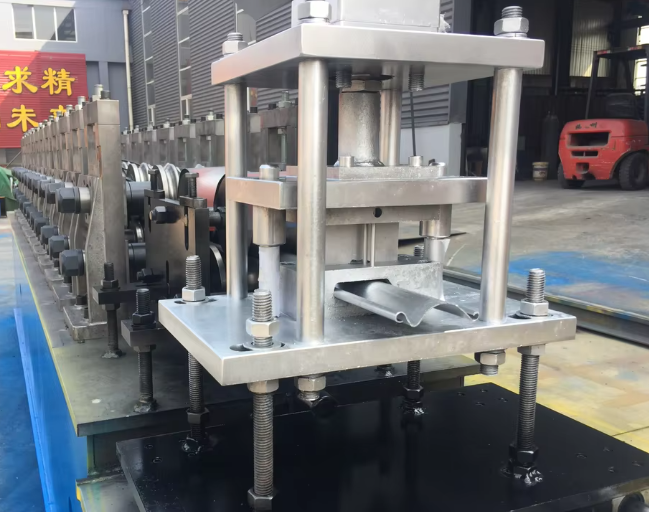

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

20-25m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

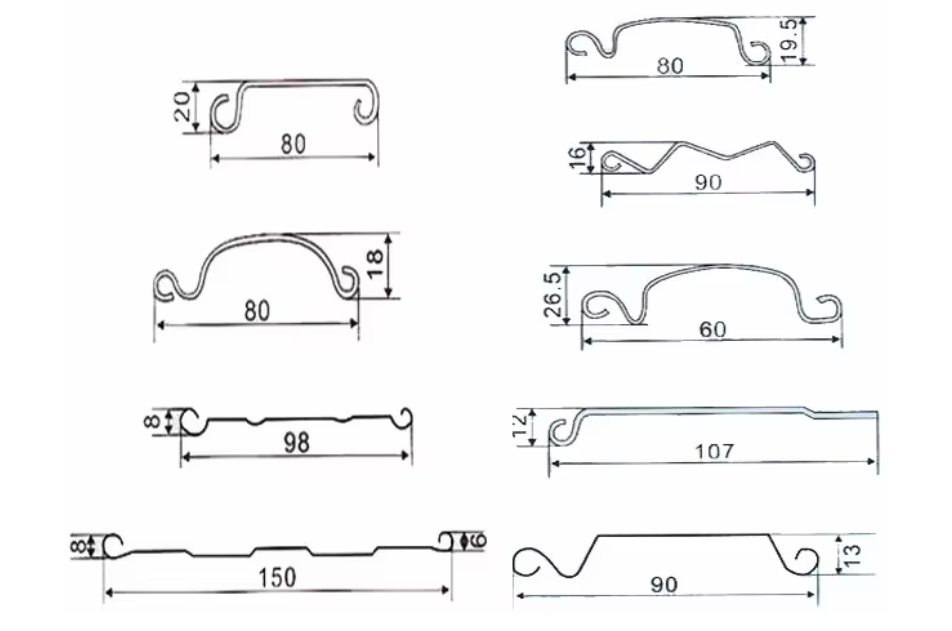

Product Description:

At the entrances of shops, warehouses, and garages in the city, rolling shutter doors operate day and night like steel curtain walls. This vertical opening and closing device, composed of metal sheets connected in series, integrates mechanical engineering and intelligent control technology, and has become an indispensable component of modern building safety systems. Roller shutter door panel roll forming machine is a type of door equipment driven by electricity, widely used in commercial or public places such as warehouses and shops. It mainly consists of a door body, a rolling door machine, and a control device. The door body of the roller shutter door panel roll forming machine is usually made of aluminum alloy or steel, and the surface is treated with multiple layers of baking paint, which has windproof, dust-proof, thermal insulation and fire resistance properties. The door has a novel and beautiful design, a compact structure, and occupies a small space, making it suitable for both interior and exterior doors of buildings.

Application scenarios:

- Industrial sites:

such as warehouses and workshops, are used to block external dust, insects, and noise, maintain a clean and quiet indoor environment, and improve work efficiency. - Commercial places:

such as shopping malls, supermarkets, restaurants, etc., are used to maintain comfortable indoor temperatures, prevent dust and insects from entering, and improve import and export traffic efficiency. - Medical field:

such as hospitals, nursing homes, etc., used to ensure hygiene and isolation, prevent pollution and transmission, and provide a quiet environment for medical treatment.

Main features:

1.Quick response:

The roller shutter door panel roll forming machine can complete the opening and closing actions in a very short time, with an opening and closing speed of 0.6-1.5 meters per second, far higher than the operating efficiency of traditional industrial doors. This rapid response capability can minimize the opening time and avoid the impact of temperature and humidity changes on the production environment.2.Efficient isolation:

The rolling shutter door is made of high-strength PVC material or aluminum alloy sheet, which has good sealing performance and can effectively block dust and moisture in the outside air, providing a stable environment for production. In addition, the fast rolling shutter door can effectively isolate different temperature and humidity environments, preventing dust and foreign objects from entering the production area.3.Security protection:

Roller shutter doors are commonly equipped with multiple safety protection devices, including bottom airbags, infrared photoelectric sensors, and emergency stop buttons. These devices can monitor obstacles under the door in real time, ensuring the safety of personnel and equipment and avoiding pinch accidents.4.Energy conservation and environmental protection:

Compared to traditional sliding doors, rolling shutter doors can reduce air conditioning energy consumption losses by about 60% annually, which is particularly important for production workshops that require constant temperature and humidity environments. For example, a packaging and printing company replaced the original ordinary door with a quick rolling shutter door in a renovation project, and recovered the renovation cost through energy saving in just six months.5.Easy to maintain:

The modular design of the rolling shutter door enables the main components such as the motor and control system to be quickly disassembled and replaced, reducing maintenance costs. Printing factories usually only need to conduct regular inspections once a quarter, including simple operations such as cleaning the tracks, lubricating bearings, and testing safety devices.Products Display: