Work flow of Trapezoidal Stainless Steel Roofing/Wall Panel Machines

Efficiency Redefined: High-Speed Production with Trapezoidal Stainless Steel Roofing/Wall Panel Machines

Stainless steel trapezoidal tiles, combining the natural advantages of stainless steel materials with the ingenuity of trapezoidal structural design, exhibit numerous advantages in architectural applications:

Significant Material Advantages

Made with stainless steel as the base material, they possess strong corrosion resistance and oxidation resistance, capable of adapting to various complex environments such as rainy areas, coastal regions, and industrial plants. This greatly extends the service life of roofs and walls while reducing long-term maintenance costs.

Excellent Structural Performance

The trapezoidal design, combined with the cold bending and rolling process, endows the tiles with high overall strength and good toughness. They can effectively withstand snow loads, wind forces, external impacts, etc., ensuring the stability of the building structure.

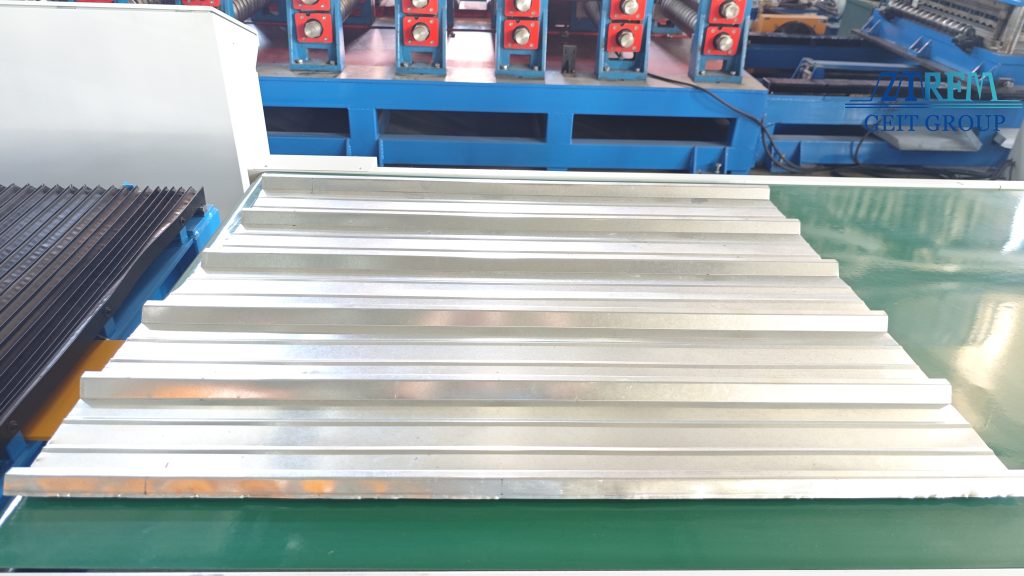

Guaranteed Processing Precision

Processed by specialized tile presses with thick pressure roller shafts and precision mold wheels, the formed tiles have accurate dimensions and neat edges. When laid, they fit tightly, reducing the risk of leakage and enhancing the neatness and aesthetics of the building’s appearance.

Wide Range of Applicable Scenarios

They can be flexibly matched with different installation methods according to architectural needs, suitable for roofs and walls of industrial factories, warehousing facilities, and commercial buildings. Moreover, the trapezoidal structure is conducive to drainage, further enhancing their practical performance.

Prominent Economic and Environmental Value

Although the initial purchase cost of stainless steel trapezoidal tiles is relatively high, their long service life (usually up to several decades) and minimal maintenance requirements result in lower long-term comprehensive costs. In addition, stainless steel materials are recyclable and reusable, conforming to the development concept of green buildings, and thus have more sustainable development advantages in the context of increasingly high environmental protection requirements.

In summary, stainless steel trapezoidal tiles integrate durability, practicality, aesthetics, and economy, making them an ideal choice for roofing and wall materials in various buildings.

The main parameters of the machine

| 01. Material | Carbon steel,Aluminum,Stainless steel etc |

| 02.Thickness of materials | 1-6mm |

| 03.Width of materials | 1000-1500mm (as customer’s request) |

| 04.Embossing roller | Dia 550mm,width:1000-1500mm |

| 05.Embossing type | Double side embossing machine |

| 06. Speed | 0-10m/min |

| 07.Materials of rollers | 9Cr2Mo |

| 08.Payment term | T/T ,D/P,D/D or L/C |

| 09. Motor | SIEMENS |

| 10. Reducer | SIEMENS |

| 11. PLC | SIEMENS |

| 12. Screen | SIEMENS |

| 13. Main electrial parts | SIEMENS |

| 14. Voltage | Customized |

| 13. Product collect table | 3m |

| 14. Bearings | Harbin |

| 15. Delivery | 40 days after confirming the order |

| 16. Warranty | 1 year |

Recommend related machine: