Quality Glazed Tile Sheet Roll Forming Machine factory:A pioneering force that reshapes the production pattern of building materials

In the bright starry sky of building materials, glazed tiles always shine with a unique light, and with their simple and elegant appearance and excellent performance, they have become the roofing material chosen by many buildings. As the core equipment of glazed tile production, the glazed tile forming machine is leading the field of building material production to a new height with its strong technical strength and innovation advantages.

Product Attributes :

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3-0.5 mm |

| 3 | coil feeding width | 1250 mm |

| 4 | Felt device | Available |

| 5 | Roller station | 14stations |

| 6 | Punching speed | 0-6 m/min |

| 7 | Motor for roll forming | 5.5 KW |

| 8 | Machine frame | Hot rolled H-beam |

| 9 | Transmission | Chains transmission |

| 10 | Roller material | High grade 45# steel |

| 11 | Shaft diameter | 80 mm |

| 12 | Cutting type | Hydraulic cutting |

| 13 | PLC brand | Delta |

| 14 | Frequency brand | Delta |

| 16 | Coder brand | Omron |

1.Efficient production and production capacity leap

The glazed tile forming machine is equipped with advanced automated production lines and intelligent control systems, among which PLC (Programmable Logic Controller) and intuitive touch screen operation interface can be called a “golden combination”. This system acts like a well-trained conductor, accurately scheduling the production process for fully automated production and real-time monitoring. The operator only needs to easily set up multiple sets of different data on the computer controller, and then confirm with one click, and the equipment can respond immediately to produce finished glazed tiles of different lengths quickly and stably according to the set requirements. This automated production mode greatly shortens the production cycle, breaks through the limitations of traditional production length, and increases the production capacity of enterprises several times. For example, after a large building materials company introduced a glazed tile forming machine, which originally required a lot of manpower and took a long time to produce the production process, now only a few workers need to monitor the operation of the equipment, and the daily glazed tile output has achieved an astonishing increase of 300%, and the improvement of production efficiency is immediate.

2. Fine carving and excellent quality

The glazed tile forming machine has reached an almost strict level of product quality control. The well-equipped hydraulic system and precision mold design of the equipment are the key to ensuring product quality. High-strength wear-resistant rollers and molds play a crucial role in the glazed tile pressing process, they act like skilled craftsmen, ensuring that each glazed tile remains highly flat and the surface is as smooth as a mirror without the slightest deformation or scratch. Whether it is a common imitation resin glazed tile, or a color steel glazed tile with a unique texture, or other styles of glazed tiles, the molding machine can accurately shape, and the size error of the glazed tiles produced can be strictly controlled within a very small range, with full and uniform color, clear and realistic texture, fully meeting or even exceeding the high standards of the industry, which can fully meet the diverse needs of different architectural styles and customers, and add eternal charm to the building.

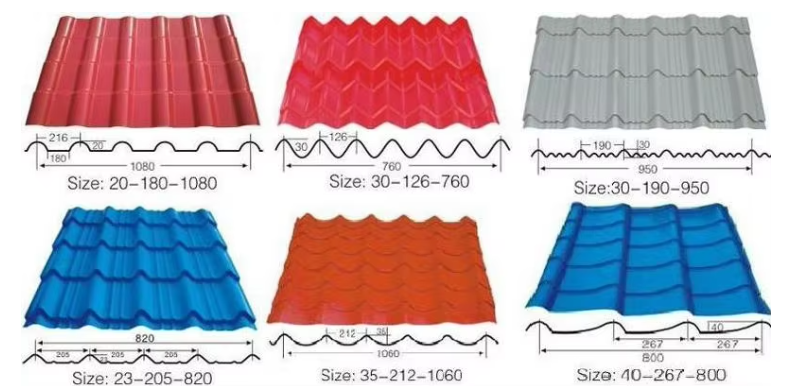

3. Diverse functions and wide adaptation

In the face of increasingly diverse market demands, glazed tile forming machines demonstrate strong adaptability and functional diversity. It can not only skillfully produce a variety of common types of glazed tiles, but also has customized production capabilities, which can flexibly adjust production parameters and mold configurations according to the special design requirements put forward by customers to create unique glazed tile products. From commercial buildings with modern and simple styles in bustling cities, to ancient building repair projects that inherit history and culture, to private residences full of warm atmosphere and villas that highlight style, the glazed tiles produced by glazed tile forming machines can be perfectly adapted, providing unique roofing solutions for various buildings, and becoming a right-hand man to improve architectural quality and aesthetic value.

4. Easy operation and convenient maintenance

The glazed tile forming machine is designed with the actual operation and maintenance needs of users fully considered, creating a friendly and easy-to-use human-computer interaction interface. The parameter setting process is simple and intuitive, so even operators without extensive professional experience can quickly get started and operate the equipment skillfully. At the same time, the daily maintenance of equipment is also simple and easy, without complex technical means and a large amount of manpower investment, which not only reduces the operating costs of the enterprise, but also reduces the equipment downtime caused by complex operation and maintenance difficulties, ensuring that the production of the enterprise can be carried out continuously and stably, so that the enterprise can focus more on the core production business.

5. Flexible transportation and quick installation

The glazed tile forming machine fully takes into account the convenience of transportation and installation in the structural design. Its compact size and light weight make it easy to move and transport, and it takes up relatively little space in the production site. This advantage allows the equipment to be quickly transferred between different construction sites, and the installation and commissioning work can be completed quickly and put into production in a timely manner. Whether it is a construction site located in the center of the city with limited construction sites, or a construction project located in a remote area with inconvenient transportation, the glazed tile forming machine can arrive smoothly and operate efficiently, providing solid and powerful support for enterprises to expand their business scope and undertake various projects, breaking the restrictions of geography and space on production.

With many significant advantages such as efficient production, excellent quality, diverse functions, easy operation and maintenance, and convenient transportation and installation, glazed tile forming machine has become an indispensable core equipment for building material manufacturers. It not only brings tangible economic benefits to enterprises, greatly improves production efficiency, reduces costs, and improves product quality, but also promotes the development and progress of the entire construction industry, helping architectural designers turn more ideas into reality. Choosing a glazed tile forming machine is to choose an efficient, intelligent and flexible production method to win the opportunity for enterprises in the fierce market competition and jointly open a new chapter in the field of building material production.