Glazed tiles, with their brilliant colors, exquisite craftsmanship and profound cultural heritage, occupy an irreplaceable position in ancient buildings and modern antique buildings. The emergence of glazed tile machines has injected scientific and technological vitality into the production of this traditional building material, realizing the perfect integration of traditional craftsmanship and modern technology.

Product Attributes :

|

1.Formed Material

|

PPGI,PPGL,AI,Etc.

|

Material Thickness:0.3-0.8mm

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

Due to your requirement profile

|

||

|

Diameter of shaft

|

Due to your requirement profile

|

|||

|

Material of rollers

|

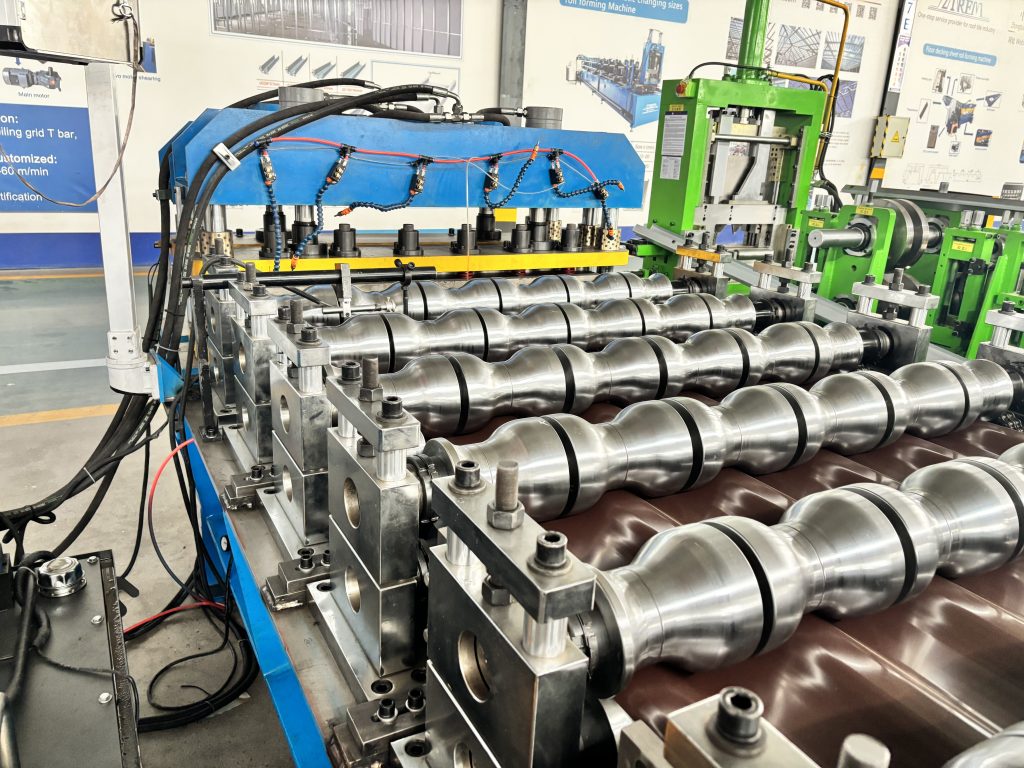

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

Due to your requirement profile

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

Due to design

|

|||

|

Weight

|

Due to design

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW(normally)

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

As your requirement

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

0-80m/min

|

Provide customized

|

||

1. Core advantages: efficient, precise and diversified production innovation

The core advantages of glazed tile machines are first reflected in the leapfrog improvement of production efficiency. Traditional handmade glazed tiles rely on the experience of craftsmen, with a daily output of only a few dozen pieces, and are greatly affected by weather and manpower. The modern glazed tile machine operates through a fully automated assembly line, from raw material mixing to finished product output in one go, and the average daily output of a single production line can reach thousands of pieces, and the efficiency is nearly 100 times higher. This advantage allows the supply of glazed tiles for large-scale construction projects to be no longer constrained by production capacity, greatly shortening the project cycle.

The stability of product quality is another highlight of glazed tile machines. Handmade glazed tiles are prone to problems such as size deviation and uneven glaze, and the machine accurately controls the raw material ratio, forming pressure and firing temperature through the CNC system to ensure that the specification error of each tile does not exceed 0.5mm and the glaze flatness reaches more than 99%. At the same time, the glazed tiles produced by the machine have higher density, lower water absorption (≤3%), wind and frost resistance far exceed traditional products, and the service life is extended to more than 50 years.

In terms of cost control and environmental performance, glazed tile machines also perform excellently. Automated production reduces manual input by more than 60%, and the raw material utilization rate is increased to 95% (only about 70% for traditional processes), significantly reducing production costs. In addition, the exhaust gas treatment system and waste heat recovery device are equipped with the machine, which can reduce pollutant emissions by 80% and energy consumption by 30% during the firing process, fully complying with modern environmental standards.

2. Technical principles: Technology empowers the precise operation of traditional crafts

The efficient operation of glazed tile machines relies on the coordination of the three core technology systems. The intelligent raw material handling system monitors the humidity and particle size of clay and glaze in real time through sensors, and automatically adjusts the water addition ratio and stirring time to ensure uniform raw material texture. This link lays the foundation for the stability of subsequent molding and firing, avoiding cracking and deformation of tiles caused by raw material problems.

CNC molding systems are the key to determining the precision of glazed tiles. The machine uses a hydraulically driven mold set that can precisely press the blank according to preset parameters such as tile curvature, size, decoration. Whether it is antique dragon pattern tiles, drip tiles, or modern and simple flat tiles, the machine can complete the switching within 30 seconds by simply changing the mold and entering the corresponding program, achieving flexible production of multiple varieties. During the molding process, the pressure sensor provides real-time feedback data to ensure the consistent density of each piece and improve structural strength.

The intelligent temperature-controlled firing system overcomes the problem of “relying on experience to see the fire” in traditional kilns. The built-in infrared thermometer and programmable logic controller (PLC) enable precise control of the temperature profile in the kiln (from preheating, sintering to cooling) with an error within ±5°C. According to the characteristics of different glazes, the system can automatically adjust the heating rate and holding time to ensure that the glaze color is uniform and the gloss is high, and the classical charm or modern texture of glazed tiles is perfectly restored.

3. Practical application: all-round performance covering multiple scenarios

The products produced by glazed tile machines have been widely used in the field of ancient building restoration and protection. In cultural heritage restoration projects such as the Forbidden City and the ancient city of Pingyao, the traditional glazed tiles reproduced by the machine are highly consistent with the original in size, decoration and color, which not only meets the requirements of “repairing the old as the old”, but also extends the life of the building with better physical properties. In the restoration project of a temple in the Ming Dynasty, the glazed tiles produced by machines were tested by wind and rain for three years, and none of them were faded or damaged, which was highly recognized by the cultural relics protection department.

In modern antique buildings, the flexibility of glazed tile machines stands out. Whether it is the roof decoration of a Chinese-style villa or the landscape pavilion of a cultural tourism town, the machine can produce customized tiles according to design needs. For example, a Jiangnan water town theme resort uses machine-produced blue-gray glazed tiles, whose curvature fits the regional architectural characteristics, and the glaze presents a natural “water ripple” effect, which not only retains the traditional artistic conception, but also reduces the maintenance cost in the later stage.

Municipal and landscape engineering has also become an important application scenario of glazed tile machines. The antique corridors in the park, the shops along the streets of the ancient town, and the roofs of the temples of religious places can all be seen with glazed tiles produced by machines. These tiles not only add a quaint aesthetic to the building, but also resist extreme weather such as strong winds and heavy rains, reducing the frequency of maintenance. In the antique archway project of a municipal park, the annual maintenance cost is reduced by 40% compared to traditional tiles after using machine glazed tiles.

From the repair of ancient buildings that have been passed down for thousands of years to the ever-changing modern architectural decoration, glazed tile machines have redefined the production standards of glazed tiles with their advantages of efficiency, precision and environmental protection. Choosing glazed tile machines is not only the choice of advanced production equipment, but also the innovative inheritance of traditional craftsmanship and the ultimate pursuit of architectural quality. Let science and technology empower glazed tile production and inject timeless charm into every building.