The Standing Seam Roof Sheet Roll Forming Machine deeply cultivates the demand for roof processing, with “high-speed forming+precise edge locking+durable sealing” as the core. It is specially tailored for mainstream roof profiles such as vertical edge locking roof panels and standing edge interlocking roof panels, completely solving the pain points of “slow speed, poor sealing, and difficult adaptation” in traditional processing. It has become the preferred equipment for roof construction of large-span buildings such as industrial plants, sports venues, and airport terminals.

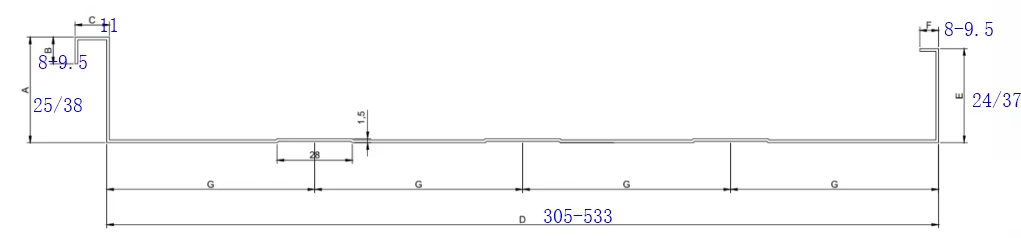

Pattern diagram:

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.4-0.8mm Width:as the profile drawing

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows (Design as the profile drawing)

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

5500*1600*1600(customize)

|

|||

|

Weight

|

3.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable as customer’s request

|

||

Industry wide adaptation, roof engineering is omnipotent

• Industrial buildings:

Processing large-span roofs for factories, warehouses, and logistics centers to facilitate the rapid construction of sealed and waterproof roofs;

•Public buildings:

iconic roof processing for sports venues, exhibition centers, airport terminals, and high-speed railway stations, balancing aesthetics and practicality;

•Commercial buildings:

roof renovation and new construction projects for shopping centers, office buildings, and hotels, suitable for complex styling designs;

•Special scenarios:

Roof processing in coastal areas, high-altitude areas, and areas with frequent rain and snow to meet wind resistance, waterproofing, and weather resistance requirements.

Machine Introduction:

1、 Rapid prototyping accelerates, doubling the efficiency of roof processing

The Standing Seam Roof Sheet Roll Forming Machine is equipped with a dual servo drive system, with a molding speed of 15-20 meters per minute, and a processing efficiency 2-3 times higher than traditional equipment. The daily output of a single machine is 1500-2000 square meters. Fully automated operation of the entire process, reducing manual intervention and process gaps, shortening processing cycles by 60%, and assisting in rapid project delivery.

2、 Precise edge sealing, fully waterproof and wind resistant performance

The equipment adopts high-precision roller group and CNC locking technology, with a forming error of ± 0.1mm and tight vertical seam interlocking. No need for glue to form a waterproof barrier, able to withstand extreme weather conditions, suitable for harsh environments, and eliminate water leakage hazards from the source.

3、 Intelligent flexible adaptation, easy switching of multi specification roofs

Built in massive processing templates, covering mainstream board types, board widths of 300-600mm, and thicknesses of 0.5-1.2mm, supporting one click switching. The 12 inch touch screen enables graphical programming, and ordinary workers can operate it with simple training. Support non-standard customization, flexibly respond to various needs, and increase equipment utilization by 40%.