In the field of CZ steel processing, efficiency, accuracy, and adaptability are the core keys for enterprises to win the market.CZ Quick Changing Model Machine Purlin Making Machine are deeply rooted in industry demand, with full automation technology as the core, integrating multiple advantages such as high-precision processing, intelligent control, and multi scenario adaptation. They are tailor-made for CZ steel and derived profiles, completely subverting traditional processing modes and becoming the preferred choice for production upgrades in industries such as steel structure construction, photovoltaic brackets, and storage shelves.

Full process automation, CZ steel processing efficiency skyrockets

The CZ steel machine solves the problems of traditional manual dependence and process disconnection in processing, achieving unmanned operation of the entire process from loading, feeding, punching, cutting to unloading. High speed servo feeding has a response time of 0.1 seconds, and the daily output of a single unit is 3-5 times that of traditional methods. The delivery cycle is shortened by more than 50%, and there is no need for dedicated personnel to be on duty, greatly improving production efficiency.

Micron level precise control, every steel profile meets the standard

Adopting imported servo and high-precision screw, the positioning accuracy is ± 0.02mm, and the hole and cutting errors are almost zero. Intelligent detection real-time monitoring, automatic compensation, ensuring accurate steel size, hole position, and length, meeting the installation needs of steel structures, photovoltaic brackets, and reducing rework.

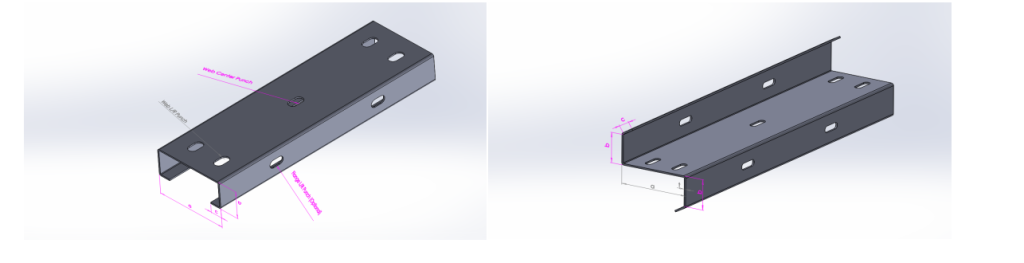

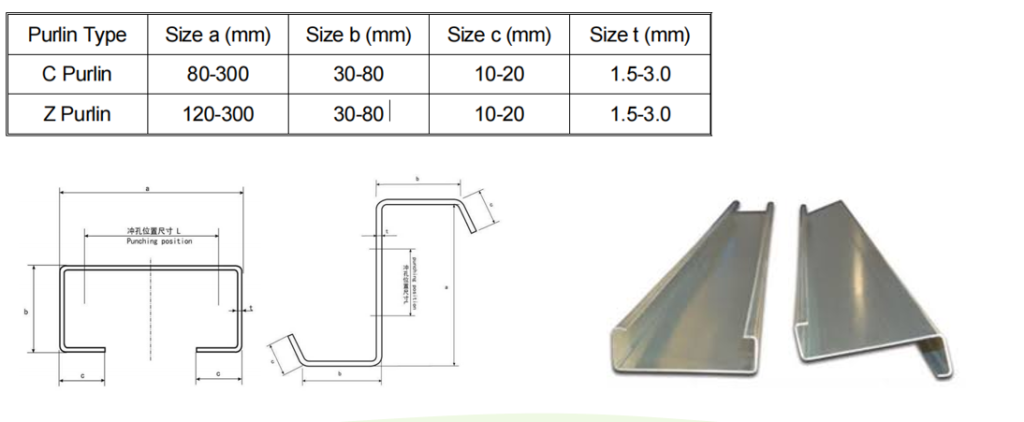

Intelligent flexible adaptation, easy switching between multiple specifications of CZ steel

Built in massive processing templates, covering various cross-sectional sizes and hole layouts, with one click switching and adaptation. The 10 inch touch screen is easy to operate, supports non-standard customized programming, and balances standardized and personalized production, increasing equipment utilization by more than 30%.

Hard core quality+economic energy saving, long-term benefits are more considerable

1. Durability: The body adopts an integral welded structure, which has undergone aging treatment to eliminate internal stress. It has strong rigidity and good seismic resistance, and can withstand high-strength processing loads of thick walled C/Z steel for a long time. Its service life is extended by 30% compared to ordinary equipment, reducing the cost of fixed asset replacement.

2. Significant energy saving and consumption reduction: Equipped with variable frequency speed regulation and intelligent power-off protection technology, it automatically reduces energy consumption in non working states, saving 25% -30% energy compared to traditional equipment. Long term operation can save a large amount of electricity expenses.

3. Low operation and maintenance costs: High quality wear-resistant materials are used for vulnerable parts, with long maintenance cycles and simple replacement operations, greatly reducing downtime and accessory wear and tear costs.

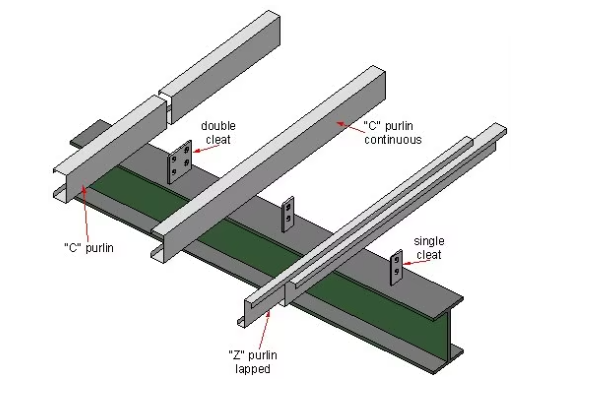

Pattern diagram:

Industry wide adaptation, C/Z steel processing is omnipotent

CZ steel machines, with their professional processing advantages, are deeply adapted to the core needs of multiple industries

• Steel structure buildings:

Processing of C/Z-shaped steel purlins, steel columns, and supporting components to assist in the rapid construction of factories, sports halls, and office buildings;

• Photovoltaic new energy:

customized processing of photovoltaic brackets (C/Z/U-shaped steel), suitable for large-scale construction of ground/roof photovoltaic projects;

• Storage and logistics:

Processing of shelf columns, beams, and layer support brackets to support the production of shelves with different loads and spans;

• Municipal and Agricultural:

Processing of greenhouse skeleton, street lamp bracket, and traffic guardrail components to meet the durability needs of outdoor scenes.

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

24 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 14T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||