Under the competitive rule of “duration is benefit” in the construction industry, the production efficiency of floor slabs directly determines the speed of project progress and the ability of enterprises to accept orders. The High Technology Roof Floor Decking Roll Forming Machine breaks through disruptive production capacity, redefining the ceiling of floor slab production speed, helping you easily grasp large-scale orders, shorten project cycles, and seize market opportunities!

Choose a high-performance floor slab machine to unlock three core benefits

✅ Upgrade order capacity:

easily win large quantities and short lead time orders, expand business boundaries;

✅ Shortening project cycle:

doubling production efficiency, accelerating project progress, and reducing capital occupation costs;

✅ Comprehensive cost reduction:

Double reduction in unit energy consumption and labor costs, improving product profitability.

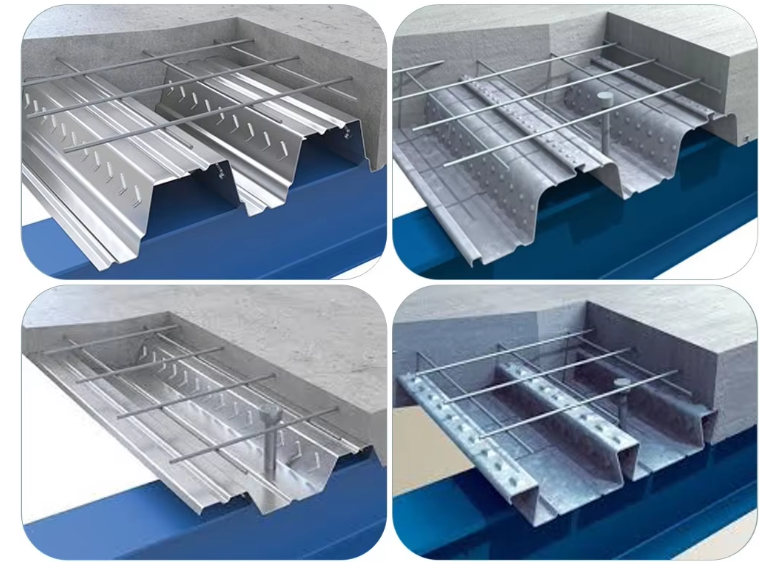

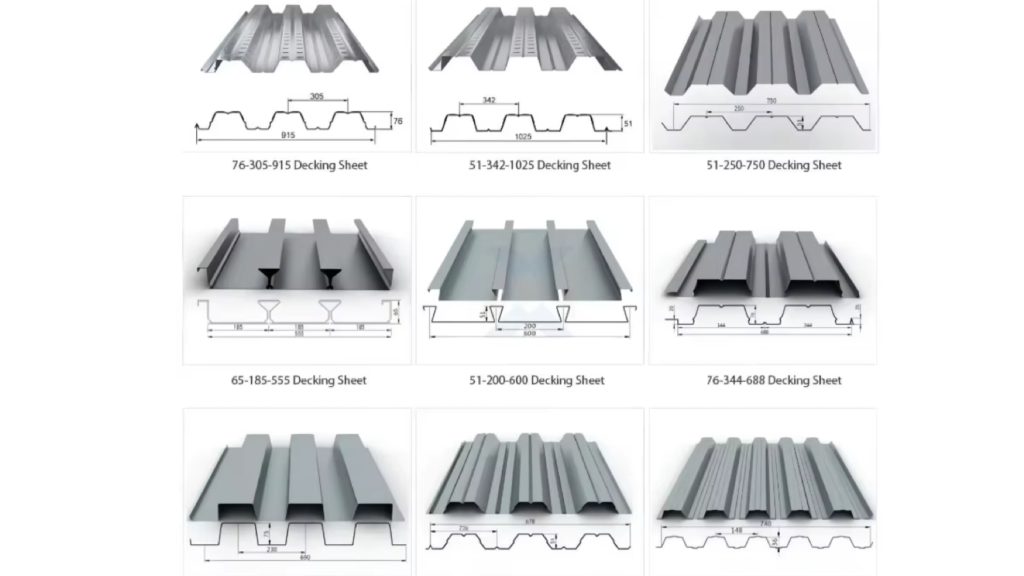

Pattern diagram:

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.7-1.6mm Width:1220mm (as request)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

28 rows(As your requirement)

|

||

|

Diameter of shaft

|

90mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600(customize)

|

|||

|

Weight

|

8T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

30KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Rapid output, every minute and second is profit

Equipped with integrated molding technology and high-speed transmission system, the roller shaft speed is 1.8 times that of traditional equipment, and the maximum output per minute is 15 meters. A single production line can meet the centralized supply of large-scale projects.

Breaking 10000 in a single day, delivering one step faster than others

Optimizing processes to reduce ineffective time consumption, with a daily output of over 8000 square meters and a peak of 10000 square meters, resulting in an efficiency improvement of over 100% compared to traditional equipment. An order of 20000 square meters only takes 2-3 days, significantly reducing the delivery cycle.

24-hour continuous production, energy-saving and stable

Heavy duty body+wear-resistant roller shaft, equipped with intelligent overload protection, supporting uninterrupted production. Optimizing energy consumption with an 18KW motor, resulting in a 25% reduction in cost per square meter.

Intelligent control, reducing labor costs by 30%

The PLC system can be started with one click, and the general engineer has been trained to control 2-3 devices simultaneously. Automatic feeding and cutting reduce manual intervention, accurately improve efficiency and reduce costs.