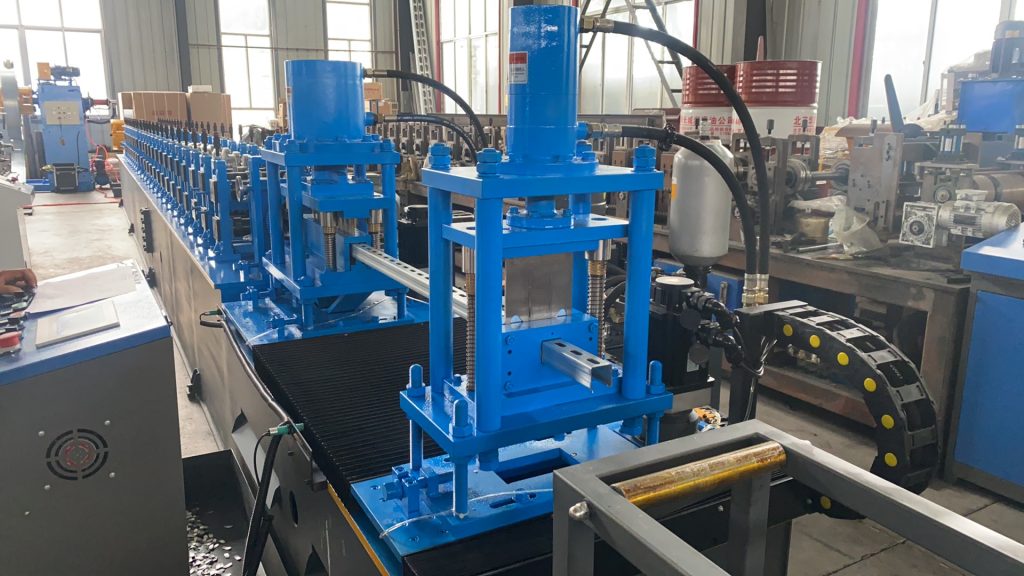

Full Automatic Steel GI Solar Structure Profile Line Forming Machine is a forming machine specially used to produce the support structure of photovoltaic power station (photovoltaic support). Through cold bending, molding, welding integration and other processes, raw materials such as steel, aluminum alloy, composite materials are processed into photovoltaic support modules (including columns, beams, slant support, clamps, etc.) with load-bearing, wind resistance, corrosion resistance and other properties.

Its core function is to:

1. Achieve standardized and large-scale production of photovoltaic brackets, ensuring the dimensional accuracy of brackets and the compatibility of component installation;

2. Improve the stability and durability of the bracket structure to ensure the long-term safe operation of photovoltaic modules;

3. Adapt to different installation scenarios (ground, roof, water surface, etc.), provide diversified support solutions, and reduce the construction cost of power plants.

Application scenarios and industry value

1.Main application areas

• Ground photovoltaic power station: Mass production of brackets for large-scale centralized power stations, suitable for terrains such as plains, mountains, deserts, etc;

• Distributed photovoltaics: customized production of brackets for industrial and commercial factory roofs, residential roofs, to meet the needs of different roof structures;

• Special scenario power stations: production of anti-corrosion brackets for fishery photovoltaic complementary, agricultural photovoltaic complementary, and water-based photovoltaic power stations;

• Building Integrated Photovoltaics (BIPV): Integrated brackets such as building curtain walls and sunshades are formed to adapt to the aesthetic design of buildings.

2.Industry value

• Replacing traditional manual welding and cutting, increasing production efficiency by 5-8 times and significantly reducing labor costs;

• Standardized production ensures the consistency of support structure, enhances the wind and snow resistance of photovoltaic power plants, and reduces safety hazards;

• Diversified materials and structural design, adapted to different climate and terrain conditions, expanding the scope of photovoltaic applications;

• Assist in achieving the “dual carbon” goal, promote the large-scale development of the photovoltaic industry, and reduce the cost of clean energy generation.

Product Attributes:

|

1.Formed Material

|

GI

|

Thickness:0.8 to 1.8 mm (standard)

|

||

|

2.Decoiler

|

3 Tons decoiler

|

3 Tons Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16 rows (As your requirement)

|

||

|

Diameter of shaft

|

60 mm solid shaft

|

|||

|

Material of rollers

|

Gcr15

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gear and chains transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW*2 sets,Siemens brand

|

||

|

Hydraulic system power

|

15 KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

25 m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

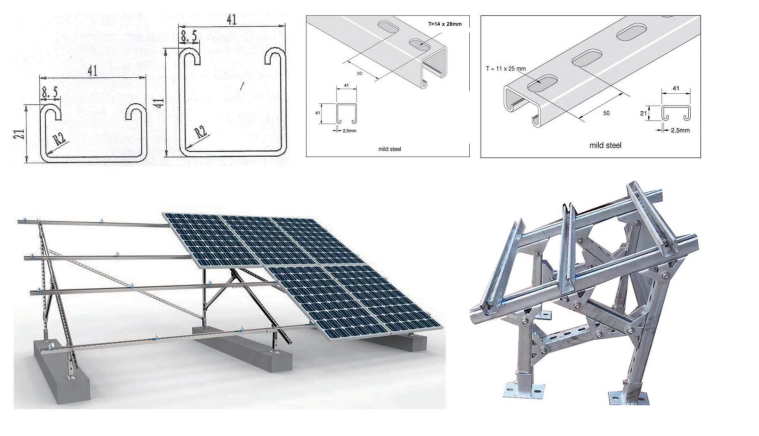

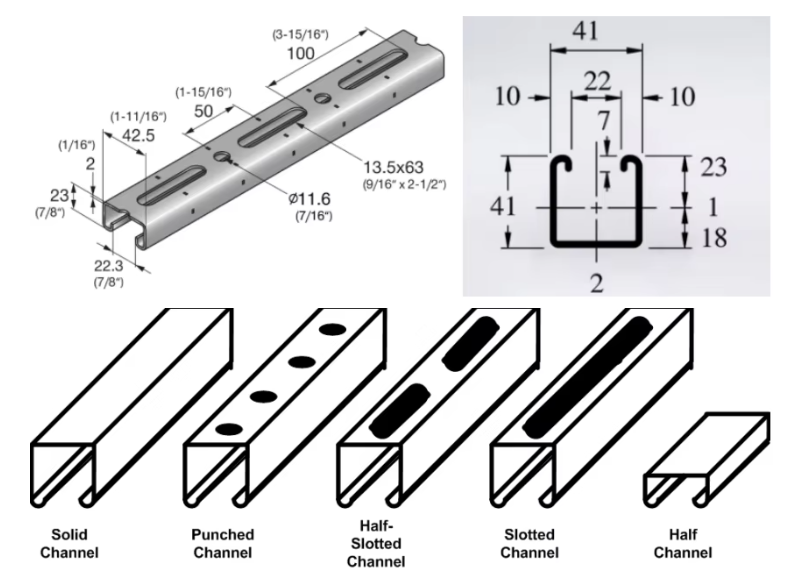

Pattern diagram:

Core technical parameters and performance requirements

• Production efficiency: molding speed 5-20m/min, cutting accuracy ≤ ± 1mm, punching efficiency synchronized with molding (no additional time consumption);

• Raw material adaptation: Compatible with raw materials of different thicknesses (steel 1.5-6mm, aluminum alloy 2-4mm) and widths, supporting customized section forming;

• Durability: The formed rolling mill adopts GCr12 bearing steel quenching treatment, with a hardness of ≥ HRC60 and a service life of ≥ 10 million times; The punching mold is made of SKD11 alloy steel, which is easy to replace.