Here is the working video of this machine for everyone to watch:

In industrial production, dust pollution not only affects the working environment, but may also cause serious damage to equipment and product quality. Taking coal mining as an example, excessive dust concentration not only threatens the health of workers, but also easily leads to equipment failure; In electronic manufacturing workshops, once dust particles adhere to precision components, it may lead to a significant decrease in product yield. To address this challenge, we have launched a dust-proof hanging machine, an innovative device that provides an efficient and reliable solution for industrial dust prevention.

Product Attributes :

|

Main frame

|

350mm H beam structure

|

|||

|

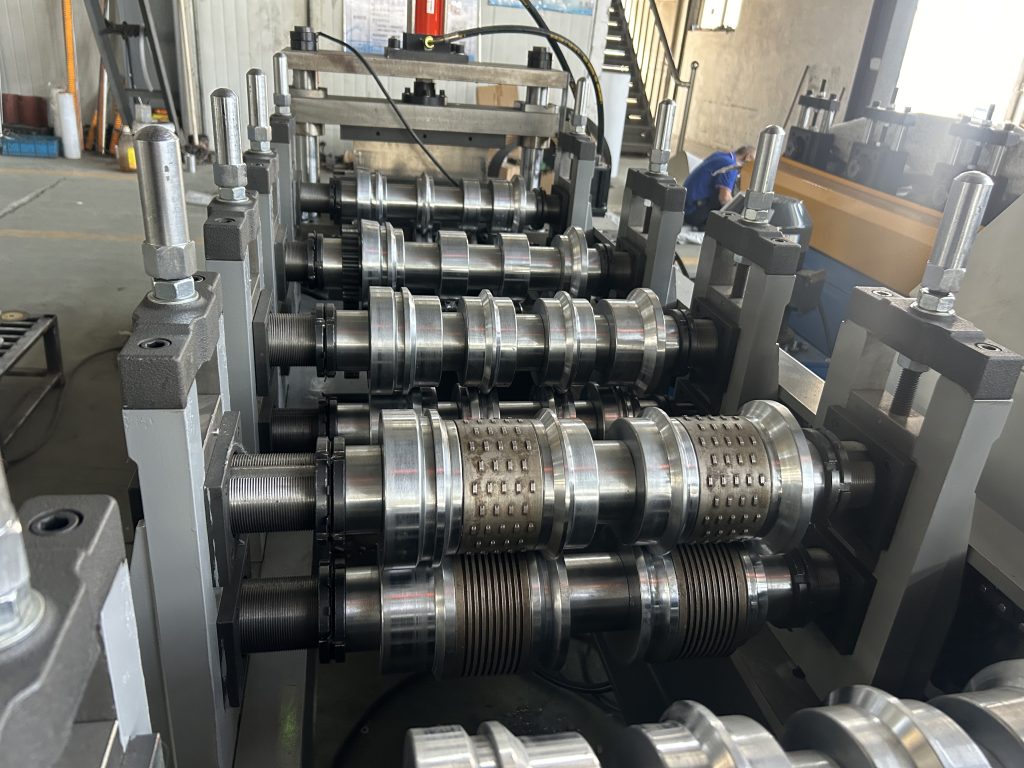

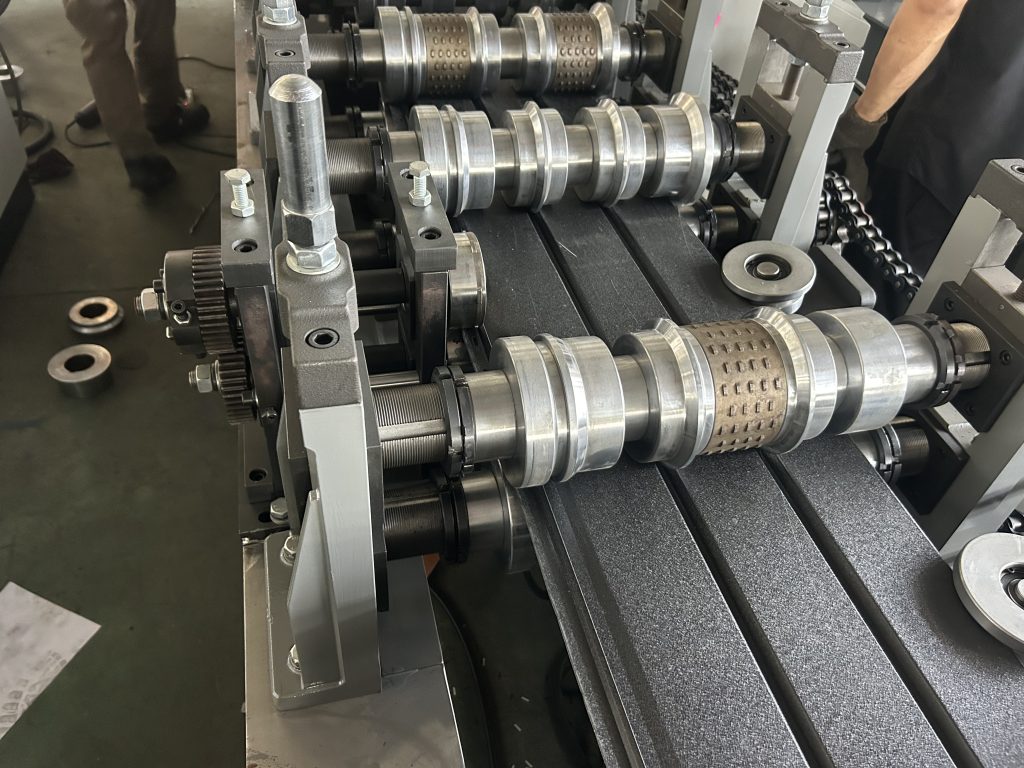

Material of rollers

|

High grade 45 high quality steel by CNC machining and hard chrome coating

|

|||

|

Forming stations

|

18 stations

|

|||

|

Diameter of shafts

|

Φ80mm solid(Guaranteed)

|

|||

|

Material of shafts

|

High grade 45#,with heat treatment

|

|||

|

Forming speed

|

About 0-30m/min

|

|||

|

Voltage

|

220V/50HZ/3P

|

|||

|

Transmission way

|

By gear box transmission

|

|||

|

Main motor

|

5.5kw

|

|||

|

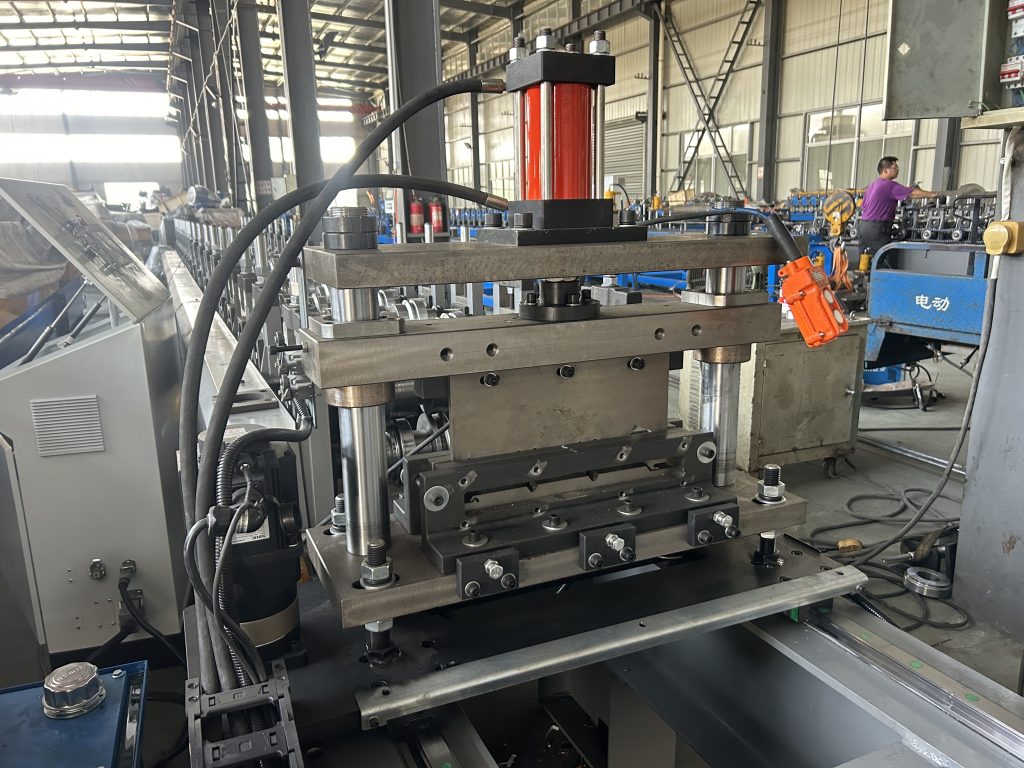

Cutting blade material

|

Cr12Mov quenched treatment to improve hardness

|

|||

|

Cutting type

|

Hydraulic cutting

|

|||

|

Driving method

|

By motor,5.5 kw

|

|||

|

Cover

|

Whole cover for roll former,without cutter.2 parts can slide side to side easily.

|

|||

1. Excellent dustproof performance:

The dust-proof hanging plate machine is equipped with a self-developed AI intelligent dust control system, which can produce various specifications of dust-proof hanging plates with an accuracy of ± 0.1mm through laser ranging and dynamic pressure sensing technology. These hanging boards have been treated with a nano level dust-proof coating on their surface, with a surface tension of 112mN/m, effectively isolating fine particles at the PM2.5 level. The unique embedded mortise and tenon structure design creates an interlocking seal between the hanging plates, coupled with EPDM rubber sealing strips, which can maintain a tight fit even in extreme temperature environments ranging from -40 ℃ to 120 ℃. Verified by third-party testing agencies, it can reduce dust concentration in the work area by more than 98.7%.

2. Efficient production capacity:

Our dust-proof hanging machine adopts a four axis linkage servo control system, which shortens the production cycle to 12 seconds per piece, and the daily production capacity of a single device can reach 3000 square meters. The intelligent scheduling system equipped on the equipment can automatically optimize the production path according to order requirements, reducing raw material loss by 30%. At the same time, the integrated visual inspection module monitors product quality in real-time, triggers automatic correction immediately upon discovering defects, and maintains a stable yield rate of over 99.2%. Through the PLC central control system, the equipment can achieve 7 × 24-hour unmanned production, which is 5 times more efficient than traditional manual production lines and reduces unit production costs by 45%.

3. Flexible customization options:

We have established a dust-proof solution database covering the entire industry, with over 1000 built-in application scenario solutions. The dust-proof hanging machine supports personalized customization, ranging from 100mm × 100mm micro experimental equipment protective plates to 20m × 3m ultra large industrial plant partition plates that can be produced. In terms of material selection, we offer 12 industrial grade materials including anti-static PVC, fire-resistant color steel plate, stainless steel, etc. The surface treatment process includes 7 processes such as frosted, mirror, and spray coating. For special needs, we can also provide functional customization such as explosion-proof and antibacterial types. We have successfully customized exclusive dust prevention solutions for high-end fields such as new energy battery workshops and semiconductor cleanrooms.

4. High quality product quality:

Each dust-proof hanging board undergoes 12 rigorous quality inspection processes, from raw material spectral analysis to salt spray testing, drop testing, and compression testing of finished products, to ensure that the products fully comply with national standards. We introduce aviation grade ultrasonic testing technology to perform non-destructive testing on the internal structure of the hanging board, ensuring zero defects before leaving the factory. All products come with a 5-year warranty. Under normal use, even in extreme environments with high dust and humidity for a long time, the dustproof performance of the hanging board will decay at a rate of no more than 0.3% per year, truly achieving long-term stability of dustproof effect.

5. Comprehensive after-sales service:

By choosing our dust-proof hanging machine, you can not only obtain high-quality equipment and products, but also enjoy comprehensive after-sales service. We have a professional technical team to provide you with comprehensive support such as equipment installation, debugging, training, and after-sales maintenance, so that you have no worries.

If you are troubled by industrial dust prevention issues, you may consider our dust-proof hanging machine. It will create a clean and safe working environment for you, helping your business achieve efficient and sustainable development. Please feel free to contact us at any time to learn more about our products and solutions.