In the field of modern architecture, the reliability and design sense of drainage systems are increasingly becoming key factors for project success. As the core component of roof drainage systems, Hot Sale Round Downspout Roll Forming Machine Gutter Guard Machine is gradually becoming the preferred solution for residential, commercial, and industrial buildings due to its unique structural advantages and material characteristics.

Product features: Dual guarantee of scientific design and durability

The circular downspout adopts fluid dynamics optimization design, and its rounded pipe body can effectively reduce water flow resistance, ensuring that rainwater is quickly and smoothly discharged into the underground pipe network. Compared with square or semicircular pipes, circular sections have larger water carrying sections under the same diameter, significantly improving drainage efficiency, especially for construction projects in areas with frequent rainstorm.

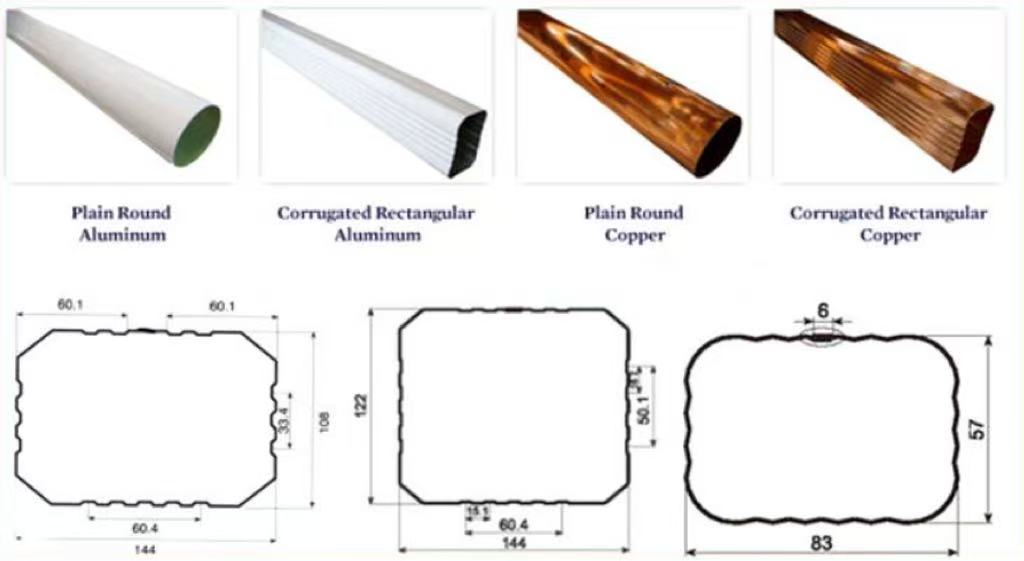

In terms of material, circular downspouts are mainly made of metal (cast iron, colored aluminum, copper) and plastic (PVC). Metal pipes, with their high strength and corrosion resistance, can withstand long-term wind and rain erosion and external pressure, making them suitable for industrial buildings or high-rise residential buildings with high safety requirements; Plastic pipes, with their advantages of being lightweight and easy to install, have become a popular choice for villas and commercial spaces, in line with the trend of modern building lightweighting.

In terms of detail processing, the circular downspout is supported in sections by fixed brackets to ensure installation stability. The plastic round tube adopts solvent bonding technology, and the joints are sealed with silicone to effectively prevent leakage; Metal pipes are reinforced with rivets and silicone, balancing strength and sealing. This refined design enables circular downspouts to maintain stable performance under complex climatic conditions, becoming the “invisible guardians” of building drainage systems.

Application scenario: Wide adaptation from residential to industrial

The multifunctionality of circular downspouts enables them to play a crucial role in various types of buildings. In the residential field, its rounded appearance and diverse material choices (such as colored aluminum, PVC) can perfectly match different architectural styles.

Commercial buildings have stricter requirements for drainage efficiency. An 8-inch aluminum alloy round downspout is used in a shopping center, with a maximum daily drainage of 500 cubic meters. It successfully copes with rainstorm weather and avoids the damage of accumulated water to the interior decoration. Industrial buildings place greater emphasis on the chemical corrosion resistance of materials.

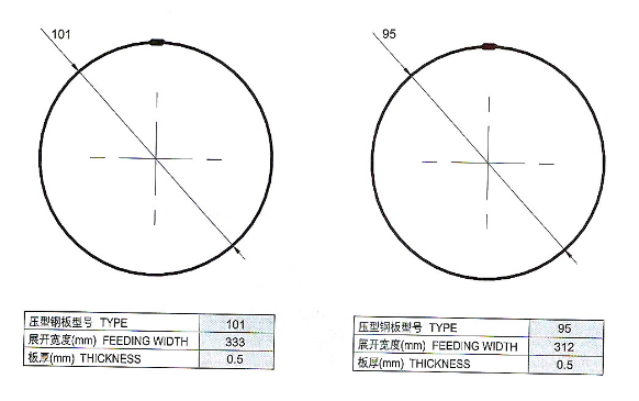

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.4-0.6mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

22 rows(As your requirement)

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

8500*1000*1200(customize)

|

|||

|

Weight

|

5.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

8-10m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

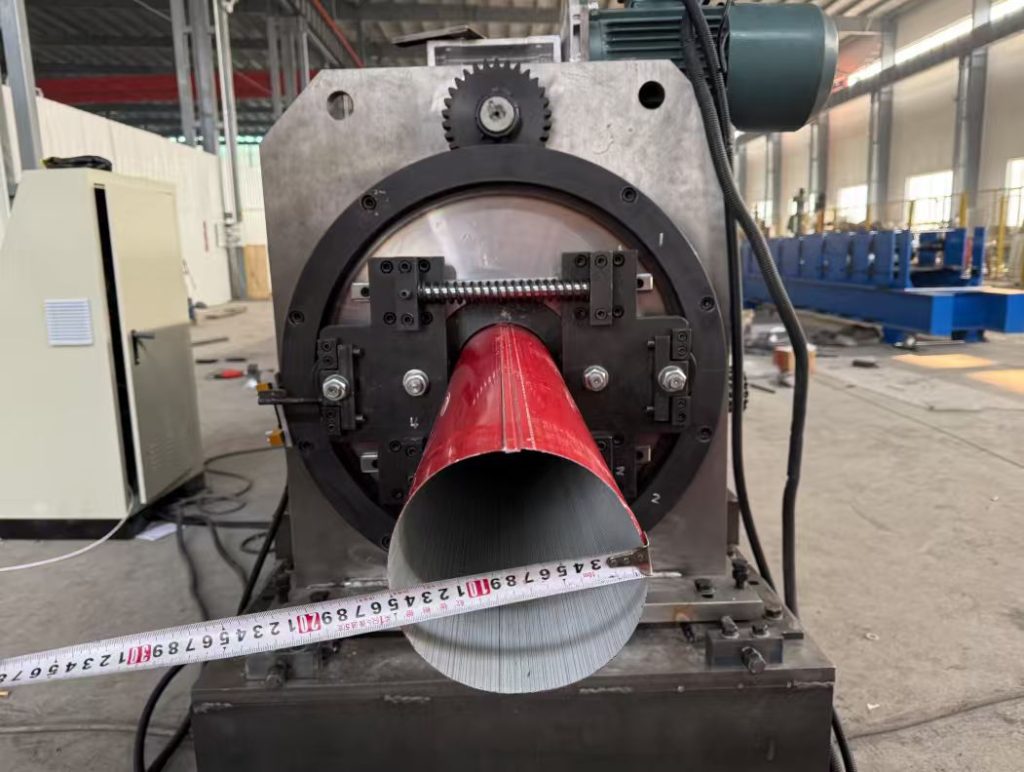

Product Display: