In today’s rapidly rising prefabricated buildings and deeply rooted green construction concepts, as the core load-bearing component of steel structure buildings, the production efficiency and quality of floor slabs directly determine the project schedule, structural safety, and comprehensive cost. An efficient, precise, and stable Customized Manufacturer Steel Metal Floor Decking Roll Forming Machine has long been a core tool for building material manufacturers and steel structure engineering companies to seize market opportunities. We have been deeply involved in the field of cold bending equipment for many years, integrating cutting-edge technology and practical experience to create a full range of floor slab equipment. With intelligent control, high standard output, and square scene adaptation, we break through traditional production bottlenecks and inject strong impetus into the high-quality development of the construction industry.

Application scenario: Global coverage, empowering various types of construction projects

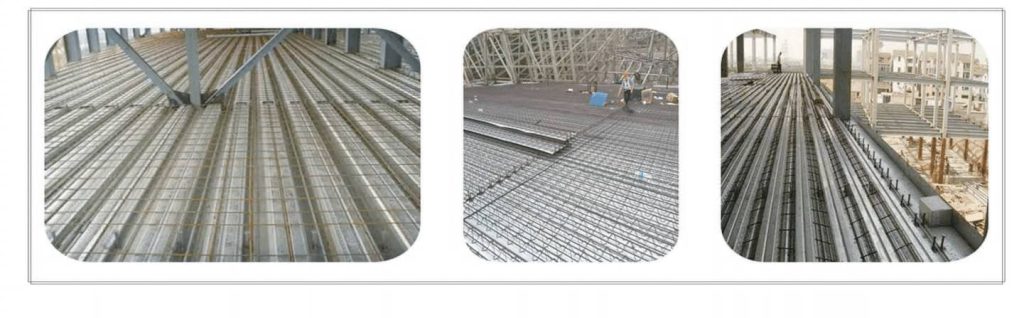

With diverse adaptability and stable and reliable performance, the products produced by our floor slab equipment are widely used in various steel structure construction projects, covering multiple fields such as industry, commerce, people’s livelihood, transportation, etc., becoming an important support for promoting the industrialization, efficiency, and green development of construction.

• Industrial plant and warehousing logistics center

Industrial plants and warehousing logistics centers have high requirements for floor load-bearing capacity and construction efficiency, and are mostly designed as large-span structures. Our company’s floor slab equipment produces floor slabs that are lightweight and have strong load-bearing capacity. They can effectively reduce the weight of buildings, lower the cost of the main structure, and meet the needs of large-span construction (with a maximum span of up to 12 meters). The high-efficiency and high-yield characteristics of the equipment can quickly meet the large-scale supply demand of floor slabs in factories and warehouses, without the need for on-site pouring, greatly shortening the construction period, especially suitable for projects such as industrial park construction and logistics park expansion with tight schedules.

• Commercial complexes and high-rise buildings

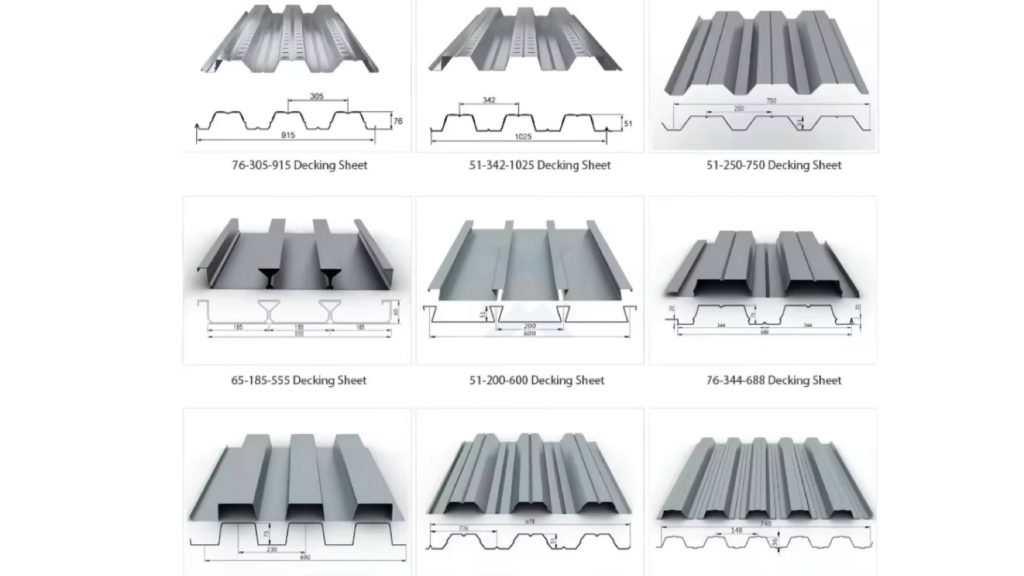

Commercial complexes, office buildings, high-rise residential buildings, and other buildings have strict requirements for the accuracy, flatness, and aesthetics of floor slabs, and the construction space is limited and the schedule is tight. Our equipment produces floor slabs with high precision and easy splicing, which can be directly laid and used, reducing on-site construction processes. At the same time, we can customize floor slabs with different waveforms and specifications according to building design requirements, adapting to the load-bearing requirements of different floors. The 750 type floor slab equipment produces slabs with a wave height of 75mm and a wave distance of 300mm, designed specifically for high-rise buildings with more than 20 floors.

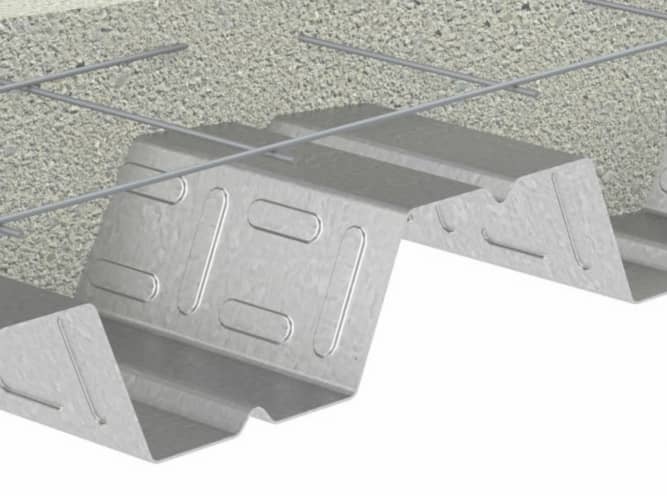

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

GI,Steel

|

Thickness:0.3-0.8mm Width:1220mm (as request)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

33 rows(As your requirement)

|

||

|

Diameter of shaft

|

90mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

13T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW*2 sets,Siemens brand

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Advantages and Characteristics:

1. Intelligent control, worry free, efficient, and labor-saving

2. Accurate molding, stable quality up to national standards

3. Efficient and high-yielding, significantly reducing production cycle

4. Energy saving and consumption reducing, green and environmentally friendly, more economical