Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness: 0.4-0.7mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler (will give you as free)

|

||

|

3.Main body

|

Roller station

|

14 rows (As your requirement)

|

||

|

Diameter of shaft

|

65mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

about 5500*1600*1600(customize)

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW, servo motor

|

||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

10-15m/min

|

The speed can be adjusted as customer’s request

|

||

Product Description:

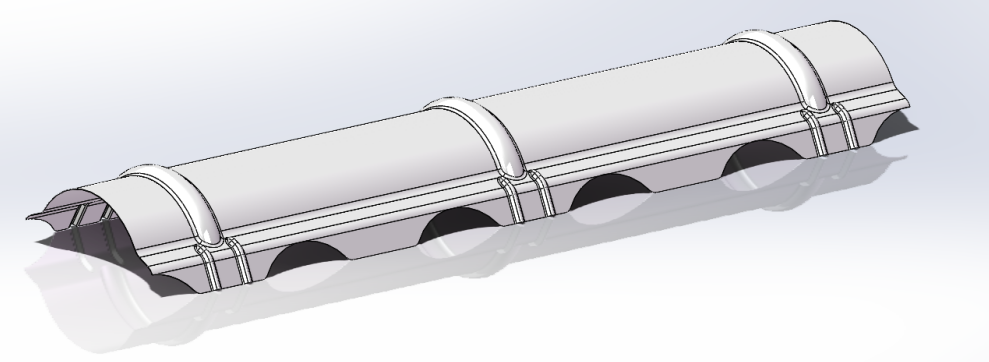

In the contemporary construction industry, ridge cap tiles are key components for roof waterproofing and decoration, and their production efficiency and quality directly affect project progress. The traditional handmade production methods are no longer able to meet the needs of large-scale construction, and the emergence of metal roof ridge cap roll forming machines is reshaping the industry’s production mode with the characteristics of automation, standardization, and efficiency. The equipment is usually controlled by PLC computer motherboard and frequency converter, with high production efficiency, easy maintenance and debugging, and replaceable molds. The equipment adopts cold bending forming technology, which is suitable for various building needs. Mainly used for urban buildings, such as warehouses, walls and protective structures of special buildings. Its characteristics are light weight, rich colors, classical elegance, easy installation and maintenance, and it also has waterproof and fireproof capabilities.

Scope of application:

- In the field of architecture:

ridge caps are used to match the spine tiles of production plants, warehouses, and sports venues, replacing the aging problem of traditional asphalt tiles. - Agricultural scenario:

Quickly customize curved roof components for agricultural greenhouses to enhance waterproof sealing. - Antique restoration:

Customized production compatible with antique decorative ridge cap tiles (such as glazed tiles).

Core advantages:

1.Efficiency improvement:

Continuous automated production replaces manual bending, saving 70% of labor costs.2.Flexible adaptation:

Supports Klip Lock style, curved and other styles of ridge tile manufacturing by changing molds.3.High yield rate:

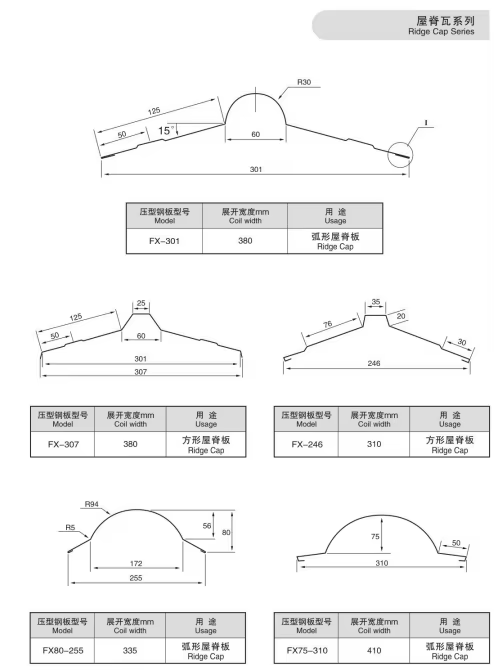

Chrome plated rollers ensure surface smoothness, with a yield rate of over 98% for finished products.Pattern diagram:

Products Display: