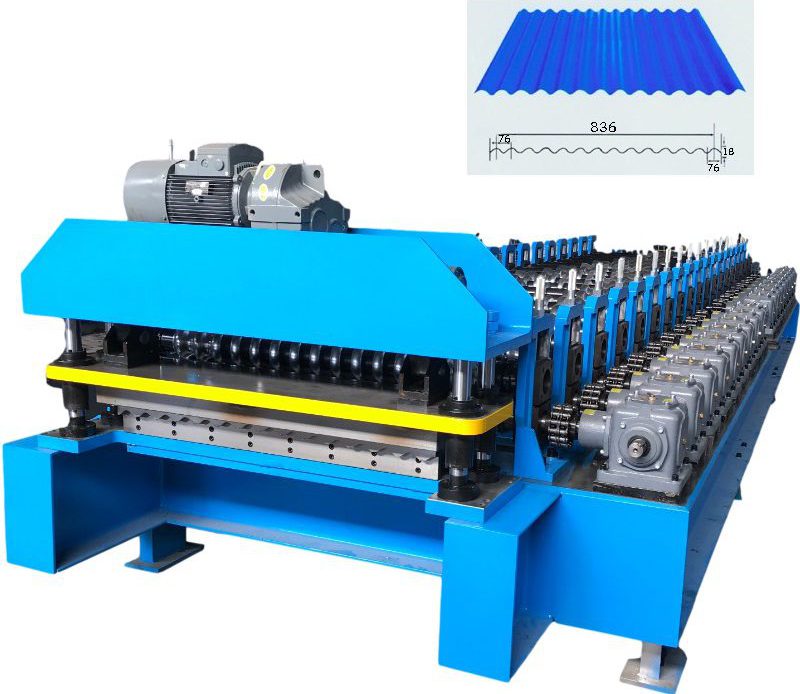

Work Flow Of Corrugated Metal Roof Sheet Roll Forming Machine

https://www.youtube.com/watch?v=PvzOKCCerZ0

Introduction to the Features and Advantages of ZhongTuo Metal Corrugated Roof Sheet Machine

In the field of construction engineering, roof sheet equipment is a key component in building roof systems, and the metal corrugated roof sheet machine, with its unique functions, holds an irreplaceable position in the processing of curved roof sheets.

Zhong Tuo’s metal corrugated roof sheet machine is a professional integrated processing and installation equipment designed specifically for arc-shaped roof sheets. Its core advantage lies in its precise cutting and forming capabilities.

It can process raw materials into various arc shapes according to the curved structural requirements of different roofs, perfectly meeting the construction standards of various curved roofs. Moreover, through an automated operation process, the equipment significantly improves the production efficiency of roof sheets, reduces manual operation links, and fundamentally ensures the structural quality and appearance uniformity of roof sheets.

As a fully automatic roof sheet forming equipment, Zhong Tuo’s metal corrugated roof sheet machine is particularly sophisticated in the selection and treatment of core components. To ensure the aesthetics and processing accuracy of products, the roller components of the forming machine are made of 45# steel and undergo a chrome plating process.

This process not only makes the surface of the rollers achieve a mirror-like smoothness but also significantly enhances the hardness and wear resistance of the rollers, effectively resisting corrosion, greatly extending the service life of the equipment. More importantly, the smooth roller surface can avoid scratches or wear on the surface of raw materials during processing, ensuring the integrity of the finished products.

In the product cutting process, the equipment is equipped with a PLC control system, which realizes the automatic control of fixed-length cutting through preset programs. This design not only simplifies the operation process, allowing workers to complete the work without complex debugging but also controls the cutting error within a very small range through digital control, further ensuring the dimensional consistency of each roof sheet and laying a solid foundation for the accurate alignment of subsequent roof installations.

Some main parameters of Metal Corrugated Roof Sheet Machine

|

parameter and

Performance |

Suitable material

|

PPGI, GI, Nano film coated plate, Aluminium etc

|

|

Material thickness

|

0.3-0.8mm

|

|

|

Main components

|

Decoiler, Roll forming machine, PLC control system, Hydraulic station, Receiving table

|

|

|

Production speed

|

0-20m/min( speed adjustable)

|

|

|

Feature

|

Main frame:350-500H beam Steel PLC: Delta or Siemens (or as your request)

Touch screen langauge: English/Chinese/as your request

Roller material: high grade 45# steel with hard chrome coated

Shaft material: 45# steel, solid

Cutting: Hydraulic cutting system

The unique feed inlet design can protect the coil paint surface and prolong the service life of roof tiles.

The cooling system on the hydraulic station can avoid overheat of hydraulic oil after long-time operate, ensure provide enough power.

|

Finished Product

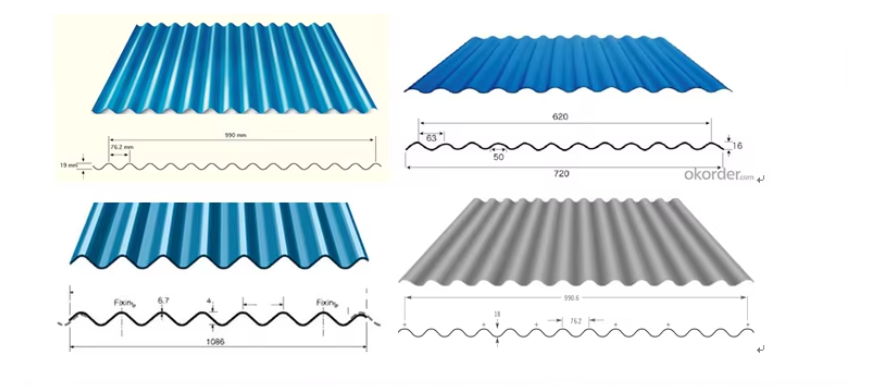

Other profile drawings

Recommended related machine