New Trends in Equipment Development

1. Intelligent upgrade

The equipment is deeply integrated with industrial Internet, Internet of Things and AI vision technology. The intelligent control system accurately monitors parameters such as raw material ratio (with an error of ± 1%) and molding pressure through sensors, and relies on the cloud to achieve remote operation and maintenance; AI visual inspection can automatically identify surface defects on wall panels with an accuracy rate of over 98%, significantly reducing quality inspection costs.

2. Low carbon transformation

In response to the “dual carbon” goal, equipment continues to make breakthroughs in energy conservation and environmental protection. Energy saving motors reduce energy consumption by 15% -20%, and waste heat recovery systems utilize 30% of maintenance heat; Innovatively applying solid waste materials such as construction waste and slag (with a maximum content of 40%) to produce recycled wall panels, achieving resource recycling.

3. Multi functional integration

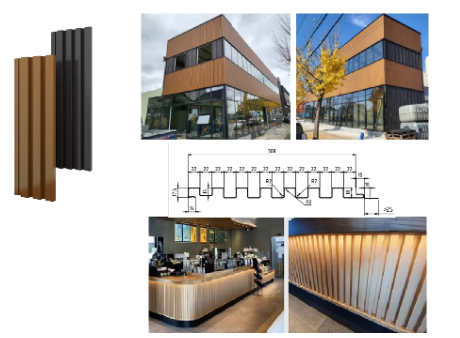

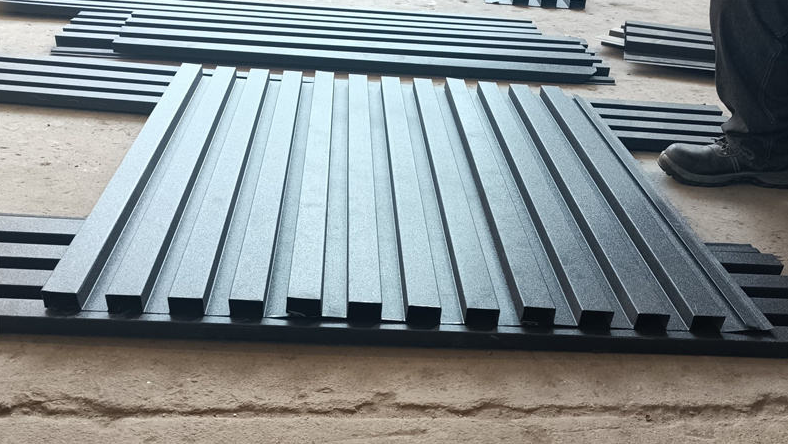

Integrated devices have become mainstream in the market. Some models support “the first mock examination for multiple purposes”, quickly switch molds within 30 minutes, and can produce hollow, heat preservation, decoration integration and other types of wallboards; Some devices are more integrated with texture suppression function, directly producing imitation stone and wood grain decorative wall panels to enhance product added value.

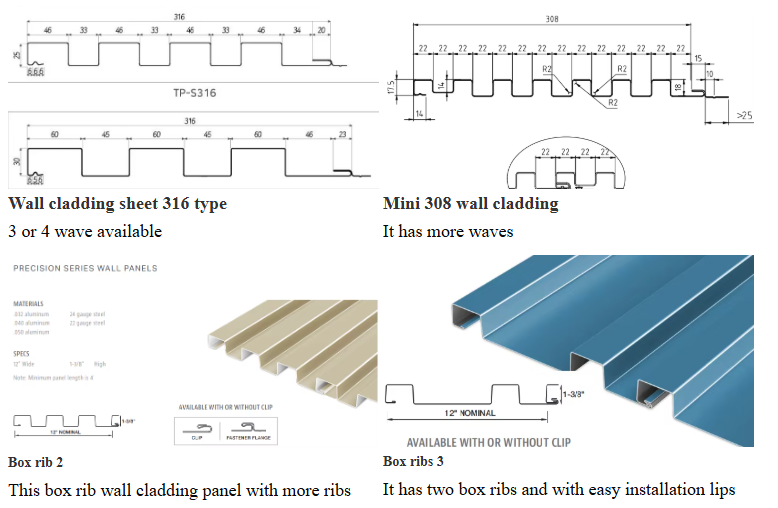

Pattern diagram:

Applicable Scenarios

• Residential buildings:

In residential buildings, wall panels can be used as interior and exterior wall materials to improve the insulation and sound insulation performance of the house.

• Commercial buildings:

In commercial buildings, wall panels can be used as ceiling and partition materials to improve space utilization and aesthetics.

• Industrial buildings:

In industrial buildings, wall panels can be used as wall materials for warehouses and factories, improving the durability and safety of the building.

• Prefabricated buildings:

The wall panels produced by the horizontal wall panel machine serve as important prefabricated components, providing strong support for the rapid development of prefabricated buildings.

• Rural housing construction and rural infrastructure:

With the deepening implementation of new urbanization and rural revitalization strategies, the application of horizontal wall panel machines in rural housing construction, rural infrastructure and other fields will continue to expand.

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-0.8mm

|

||

|

2.Decoiler

|

Hydraulic decoiler

|

Manual decoiler(will give you as free)

|

||

|

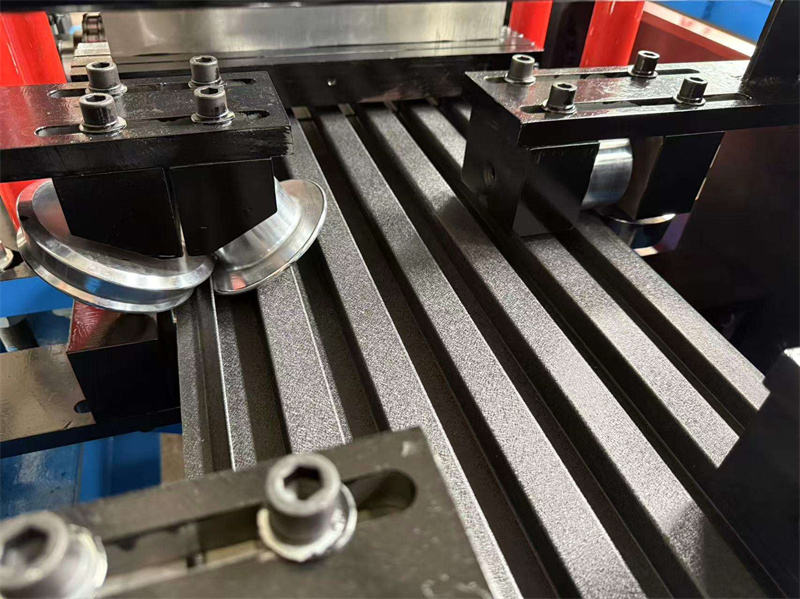

3.Main body

|

Roller station

|

28 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600mm

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||