In today’s rapidly developing warehousing and logistics industry, shelves serve as the core storage carrier, and their “heart components” – the production efficiency, load-bearing strength, and specification adaptability of shelf columns – directly determine your order taking ability and market competitiveness!

Are you still troubled by these issues?

1. Traditional manual welding has low efficiency, and it takes half a day to process a single column?

2. Is it troublesome to switch specifications and dare not accept multiple batches of small orders?

3. Poor precision of columns, inadequate load-bearing capacity, and continuous customer complaints?

Don’t let production shortcomings slow down warehousing business! Shelf System Upright Roll Forming Making Machine, based on “efficient mass production and precise quality as the core”, reconstructs the shelf column production process, helping you easily win various warehousing orders!

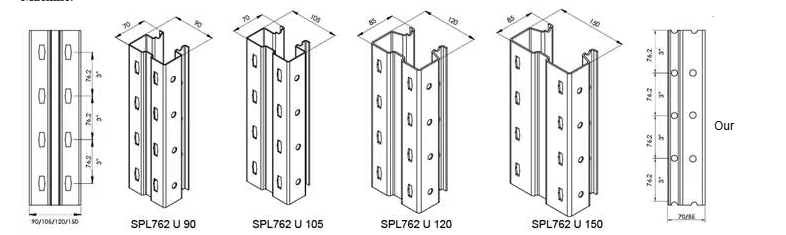

Pattern diagram

Application Fields

- Storage and logistics industry:

In the warehousing and logistics industry, shelf pillar equipment is essential. Warehousing and logistics companies typically require a large number of shelves for storing and distributing goods. Shelf column equipment can efficiently produce shelves of various specifications and models to meet the different storage needs of enterprises. - Retail industry:

In the retail industry, shelf pillar equipment also occupies an important position. Various retail enterprises such as supermarkets, convenience stores, and department stores require a large number of shelves to display goods in order to meet consumers’ choices and purchasing needs. Efficient shelf pillar equipment can produce shelves of consistent specifications and stable structure, helping retail enterprises effectively organize and display goods. - manufacturing

In the manufacturing industry, shelf pillar equipment is widely used in production workshops and warehouses. Manufacturing companies need to use various shelves to store and organize materials and parts, providing the materials and tools needed for production. Shelf column equipment can quickly produce shelves of consistent specifications, durability, and stability, improving production efficiency and quality.

Seize the storage track, start with this equipment!

The current annual growth rate of the warehousing and logistics industry exceeds 15%, and the demand for shelves continues to explode! Choosing Shelf System Upright Roll Forming Making Machine not only solves the problems of production capacity and quality, but also allows you to seize the opportunity in order bidding. Currently, the equipment has served more than 1800 warehousing equipment enterprises nationwide, helping customers increase their average annual order amount by more than 6 million!

Product Attributes

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-2.0mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

14 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 12 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 8T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

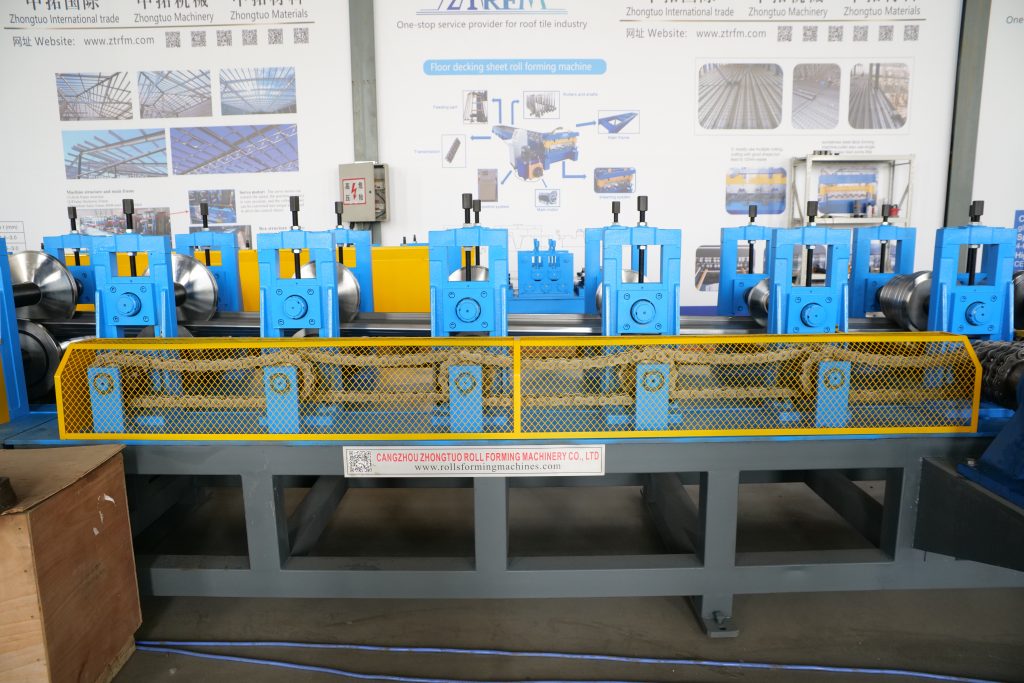

Efficient mass production ‘skyrockets’, with daily production capacity exceeding a thousand units

The equipment innovates the production mode with a fully automated assembly line, and the entire process from metal coil input to finished column output is fully automated. A single production line can process 80-120 standard columns per hour, with a maximum output of over 1000 columns in 8 hours. Under 24-hour continuous production, the capacity utilization rate reaches over 96%. Compared to the traditional production of only 50 pieces per day for 5 people, the delivery cycle has been reduced by 70%.

Precision molding+super strong load-bearing capacity, quality can withstand the “ton level test”

Multiple sets of precision rollers ensure that the column hole position error is ≤ ± 0.2mm, the straightness error is ≤ 1mm/m, and it is compatible with various materials ranging from 1.5mm to 5mm. The load-bearing strength is increased by 25%, and the material utilization rate is as high as 98%. Customer feedback shows that 100000 orders can be delivered within 20 days, resulting in a 40% increase in repurchase rate.

Flexible adaptation to full specifications, with one device supporting up to N devices

15 minute quick mold change covers column production with a width of 50mm-200mm and a length of 1.2m-6m. It is compatible with various materials such as cold-rolled steel and supports customized module expansion, reducing production cycle by another 30%.

After sales+guarantee, ensuring worry free production for you

Provide free on-site survey, installation and debugging, 24-hour technical response to ensure worry free use.