Product Attributes :

Power:5.5KW+3.0KW

Size: 5.8m×1.2m×1.65m

Weight:3 tons

Materialof rollers: 45#CNC manufactures with

chrome quenching

Drive:Chain and gear

Steps of rollers: 9rows

Material of cutting blade:Cr12 1 Mov

ElectricalStandard:220V/60HZ/3PH

Forming Speed: 15m/min

Control System: PLC (Omron)

Uncoiler Capacity: 6 tons

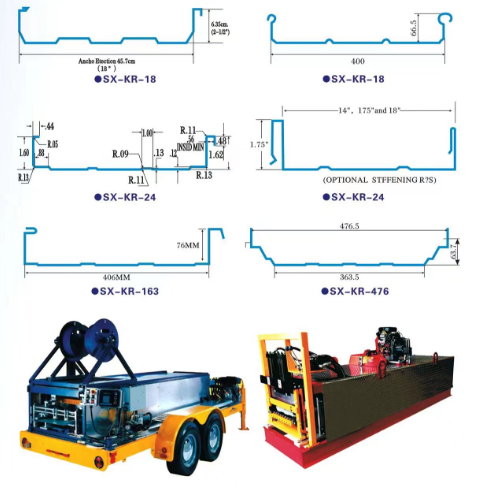

The advantage of this KR 18 Standing Seam Machine:

1.Efficient production:

Install wheels in the machine,so it can go to the construction site and produce onsite.Using on-site pressure plate equipment for production, the length of the board can be customized according to actual needs, simplifying on-site splicing work, improving construction efficiency, and helping to shorten the overall construction period.

2. Precision machining:

The equipment is equipped with a feeding positioning device to ensure the accuracy of sheet metal processing. The application of electric scissors enables the last sheet of board to be automatically cut without generating waste, which is both environmentally friendly and efficient.

3.Flexible adaptation:

The upright seam lock edge board can be flexibly bent into various shapes such as inner arc, outer arc, fan-shaped, etc., to meet the needs of various architectural styles, such as the production of spherical, S-shaped, ring-shaped and other irregular roofs.

Product Description:

KR 18 standing seam machine is a device that can be moved to the construction site for roof panel forming and edge locking treatment. By using roll forming technology, metal coils are directly processed into upright seam roof panels, supporting diversified panel customization such as trapezoidal and upright lock edge shapes. The equipment integrated with vehicle mounted design produced by Zhongtuo can be flexibly transferred to different construction sites, achieving a “mobile factory” operation mode and reducing material transportation costs.

Products Display: