Product Description:

Metal Steel C Profile Stud and Track Drywall Profile Roll Forming Machine:

In traditional architecture, brick and concrete partition walls have long dominated, but their defects such as long construction period, high self weight, and easy cracking are becoming increasingly prominent. With the rise of prefabricated buildings, the light steel keel partition system has achieved a dual breakthrough in construction efficiency and environmental performance through the mode of “industrial production+on-site assembly”. And the core support of all of this is the metal steel c profile stud and track drywall profile roll forming machine – this precision equipment that transforms steel strips into building skeletons, quietly rewriting the construction logic of modern architecture. The metal steel c profile stud and track drywall profile roll forming machine adopts a PLC control system, which has the characteristics of high efficiency and high degree of automation, and can greatly improve production efficiency. The produced profiles are widely used in the construction industry, suitable for manufacturing non load bearing partition wall systems and ceiling keel frames, and suitable for various places such as offices, residences, and shopping malls.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.8-1.2 mm (As your requirement)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

will give you as free

|

||

|

3.Main body

|

Roller station

|

10-20rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

customized

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Application scenarios:

- Indoor partition wall:

used for separating indoor spaces in factories, office buildings, offices, shopping malls, supermarkets, and other places. - Ceiling system:

As the main material for the ceiling keel frame. - Light steel villa:

used for the main structure of low rise light steel villas and the partition walls of high-rise buildings.

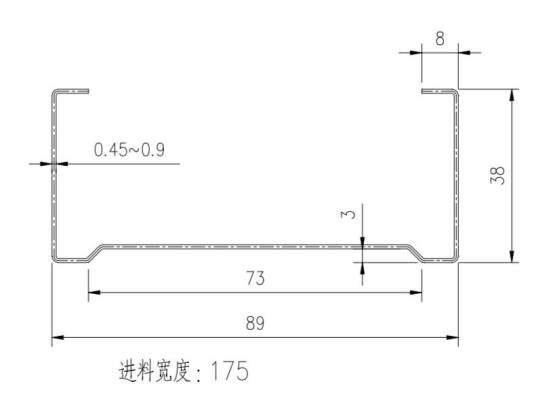

Pattern diagram:

Products Display:

Why Choose Us:

Company Profile:

Zhongtuo cold roll fonming machinery is one of the leading Chinese coil handling equipment brand founded in 2006.Our mission is to provide our customers with the very best quality metad rolling automalion solutions and afer-salesservice, Our machine offers a wide range of coil feeding equipment, ineluding Decoiler, Steel Straightener, Coil Feederas well as numerous rolling automation machines like color steel roofing sheet machines, purline machines, hotflming machine and others, Mletal eoll proeessing can be eanied out more eficiently and more accurately for betterneliability, less waste, and improved productivity.

Product packaging:

Packing method :Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),oaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.

Collaboration case:

Our machines have been exported to multiple countries and have established cooperation with multiple countries. At present, the product has successfully entered emerging markets such as Southeast Asia, the Middle East, Africa, and South America, and has established long-term stable cooperative relationships with well-known local construction companies. Through strict ISO and CE certification, our machines have won wide recognition from international customers for their excellent stability, efficient production efficiency, and intelligent operation interface. In the future, we will continue to deepen our global layout.