Two Waves Road Barrier Guardrail Roll Forming System

The new generation of Two Waves Road Barrier Guardrail Roll Forming System, wielding technology as its blade and quality as its foundation, redefines traffic safety standards by erecting an “invisible shield” for vehicular flow, safeguarding lives and ensuring security.

Core advantages, forging irreplaceable protective strength

• Super strong impact resistance, buffering and loss reduction black technology

Using Q235/Q345 special steel, after hot-dip galvanizing and spray coating treatment, the impact strength is increased by 40%. The innovative waveform structure can absorb over 80% of the impact force, effectively avoiding rollover accidents and reducing casualties.

• Durable, corrosion-resistant, and adaptable to all scenarios

Hot dip galvanized layer ≥ 85 μ m, salt spray test for over 5000 hours, suitable for extreme environments, with a lifespan of 15-20 years;

Electrostatic spraying has strong weather resistance, long-lasting bright warning colors, and enhances nighttime recognition.

• Modular design and efficient installation and maintenance

Standardized component splicing installation, with an average installation distance of 800 meters per day for 3 people. Universal accessories, quick replacement for local damage, reducing maintenance costs by 30%.

• Multi dimensional adaptation and precise protection

Support customization of the entire road section, and upgrade components such as reflective signs and anti glare panels can be configured as needed for high-speed mainlines, overpasses, tunnels, and other scenarios, achieving integrated protection and warning.

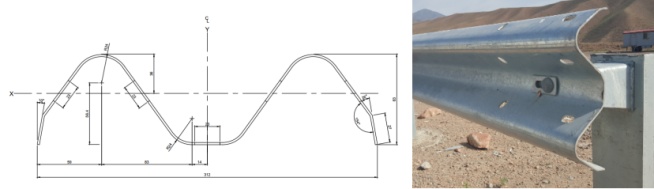

Profile drawing that Two Waves Road Barrier Guardrail Roll Forming System make

Product Attributes

| Suitable material | Q235 color steel coils;0.3-0.7mm;1220&1450mm coil width |

| Forming speed | About 20- 25m/min |

| Power Requirement | Main motor power: 55 Kw(Depend on final design) |

| Hydraulic station power: 5Kw(Depend on final design) | |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel, with heat treatment.Roller grinder milling. |

| Shaft diameter | 82mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 11500KGS |

| Machine’s size | About 18m×2.2m× 1.5m (Depend on final design) |

| Shipping | 1x40GP container can load one machine |