Standing Seam Roll Former

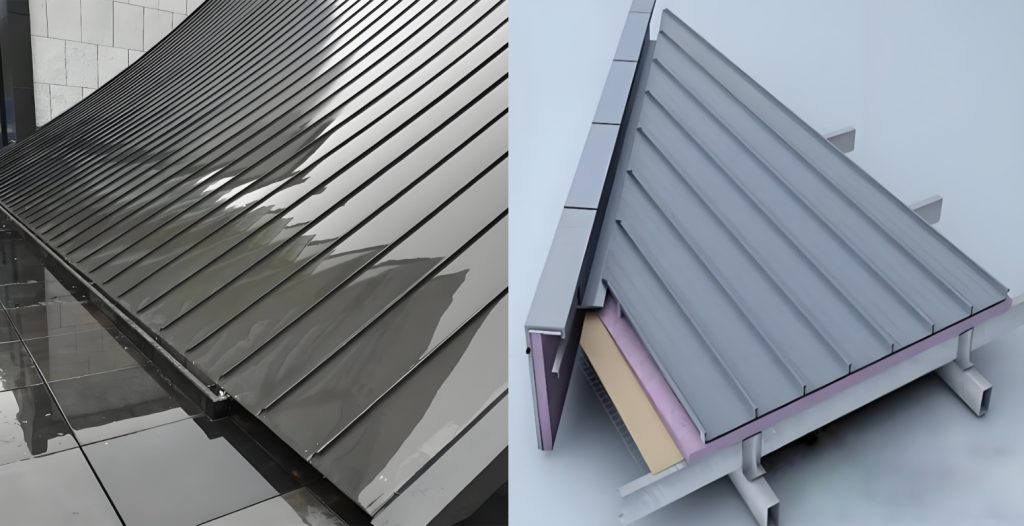

The Standing Seam Roll Former is an automated forming equipment dedicated to the production of metal vertical seam roof systems. Its core function is to roll raw materials such as aluminum magnesium manganese plate, galvanized steel plate, and color coated steel plate through multiple passes to form roof panels with vertical locking edges. With the use of specialized locking edge technology, it achieves 360 degree mechanical sealing. The finished product is waterproof, wind resistant, and has long span adaptability, becoming the core equipment for high-end building roofs.

Main application scenarios

1.Large public buildings

such as airport terminals, sports halls, exhibition halls, etc. require long span roofs and clean appearance (hidden fixed seats without exposed screws);

2.Industry and warehousing:

Steel structure factory buildings, logistics warehouses, suitable for large-span design to reduce the amount of purlins and lower costs;

3.Special environmental buildings:

coastal typhoon areas (wind resistant), low slope roofs (1 ° -2 ° compatible), chemical industrial parks (corrosion-resistant coated sheet compatible).

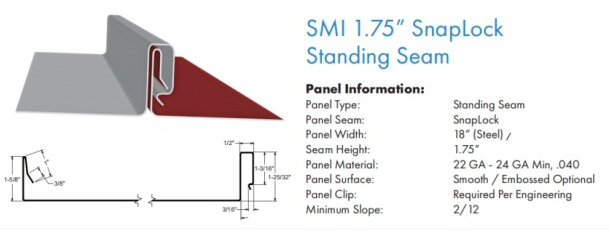

Profile drawing that Standing Seam Roll Former makes:

Product Attributes

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.4-0.8mm Width:as the profile drawing

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows (Design as the profile drawing)

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

5500*1600*1600(customize)

|

|||

|

Weight

|

3.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable as customer’s request

|

||

Core processing capability

1. Adapt raw materials and parameters

• Material range:

compatible with aluminum magnesium manganese plate (0.7-1.2mm), galvanized steel plate (0.5-1.0mm), color coated steel plate (0.5-0.8mm), etc. The yield strength of the substrate can reach 235-345MPa, and it is suitable for anti-corrosion substrates such as AZ150 aluminum zinc plating;

• Finished product specifications:

Customizable peak height (such as 51mm, 65mm), effective coverage width (300-500mm), and multi version switching (such as YX51-500, YX65-400) can be achieved by replacing the rolling mill to meet different roof load requirements.

2. Core characteristics of finished products

• Vertical seam structure:

The edges of the plates are rolled to form vertical ribs, and adjacent plates can be sealed with a 360 degree double bite to eliminate the risk of screw penetration and water leakage;

• Performance advantages:

The finished section modulus is high, and the spacing between purlins can reach more than 6 meters. It is suitable for low slope roofs of 1 ° -2 °, and its wind resistance meets the requirements of typhoon areas.