Below is a work flow video for you to watch:

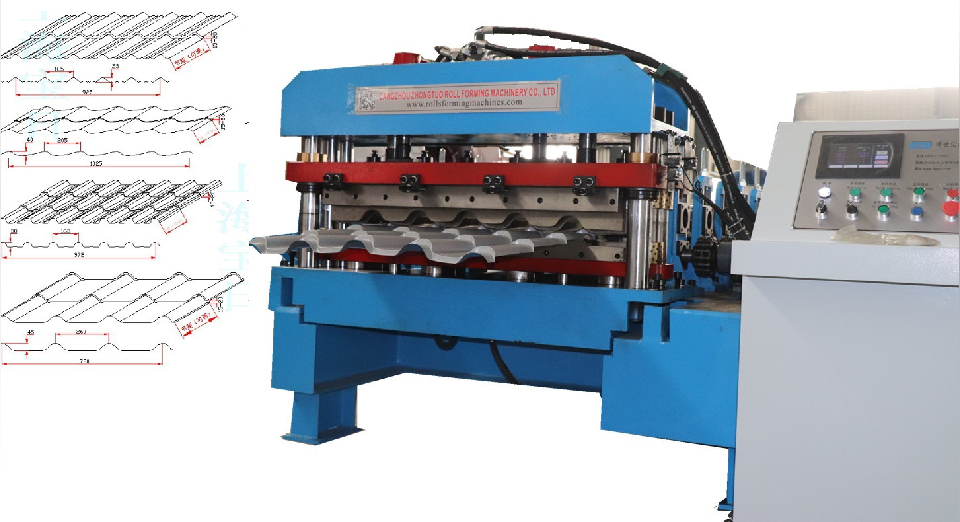

Gearbox Driven Glazed Tile Roll Forming Machine

Why choose us?

The keyway of the roller and the keyway of the shaft are tightly matched, and the roller will not slip. The shaft is processed twice by lathe, once by grinder, and twice by milling machine to ensure dimensional precision and roller fit accuracy.

The gearbox driven glazed tile roll forming machine is a device that uses gearbox transmission technology, mainly used for producing glazed tiles. This equipment mainly consists of three parts: roller forming, pressing, and cutting blades. The roller forming part is driven by chains and motors to rotate each roller, while the pressing part is driven by hydraulic cylinders to move the mold up and down, achieving the pressing and forming of tiles. The cutting blade part is used for fixed length cutting of tiles.

The glazed tiles produced by the gearbox driven glazed tile roll forming machine have various advantages, such as diverse colors, good surface gloss, corrosion resistance, acid and alkali resistance, aging resistance, good impact resistance, thermal insulation, sound insulation, etc. These tiles are widely used in various building scenarios, including roofs, walls, etc., and can meet different building needs.

The gearbox driven glazed tile roll forming machine has the following characteristics:

- Transmission method:

Gearbox transmission is adopted, and each molding frame is equipped with a gearbox to ensure that the equipment can maintain stable operation for a long time under high-intensity operation. - Control system:

usually controlled by PLC, with multiple safety protection functions to ensure safety during the production process. - Material selection:

The molding mold is made of high hardness materials, such as Cr12, which have undergone quenching treatment to ensure the durability and molding effect of the mold.

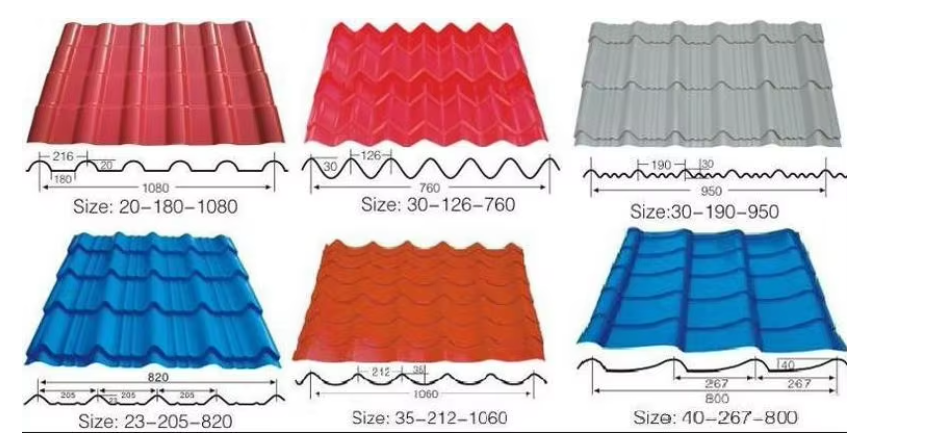

Theres some profile drawings for you reference:

Product Attributes :

|

1.Formed Material

|

PPGI,PPGL,AI,Etc.

|

Material Thickness:0.4-0.6mm

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

Due to your requirement profile

|

||

|

Diameter of shaft

|

Due to your requirement profile

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

Due to your requirement profile

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

Due to design

|

|||

|

Weight

|

Due to design

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW(normally)

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

As your requirement

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

Products Display: