Below is a work flow video for you to watch:

Why choose us?

The keyway of the roller and the keyway of the shaft are tightly matched, and the roller will not slip. The shaft is processed twice by lathe, once by grinder, and twice by milling machine to ensure dimensional precision and roller fit accuracy.

Product Description:

The main function of the corrugated sheet making metal roof forming machine is to produce corrugated sheets. The machine can produce profiled sheets with smooth appearance, uniform ripples, high strength, and high utilization rate through rolling forming technology. These profiled plates are not only aesthetically pleasing and innovative, but also have low production costs and are suitable for various building needs. Zhongtuo provides customized production and can design and manufacture according to customer needs, providing one-stop services from production to installation and commissioning. The machine produced corrugated sheets are suitable for various buildings, such as factories, garages, sports venues, exhibition halls, cinemas, etc., both beautiful and practical.

The corrugated sheet making metal roof forming machine has the following characteristics:

- High production efficiency:

The corrugated sheet making metal roof forming machine can achieve automated continuous production, greatly improving production speed compared to traditional manual production. It can produce a large number of products in a short period of time, meeting the needs of large-scale engineering construction.

- High dimensional accuracy:

Through precise mold forming and process control, the dimensional accuracy and shape consistency of tiles can be ensured, and the product quality is stable and reliable, reducing differences and defects caused by manual production. The roller part of the forming machine is usually made of 45 # steel and chrome plated to make the roller surface smoother, improve the hardness of the roller, prevent wear and corrosion, and extend the service life of the machine.

- Save labor costs:

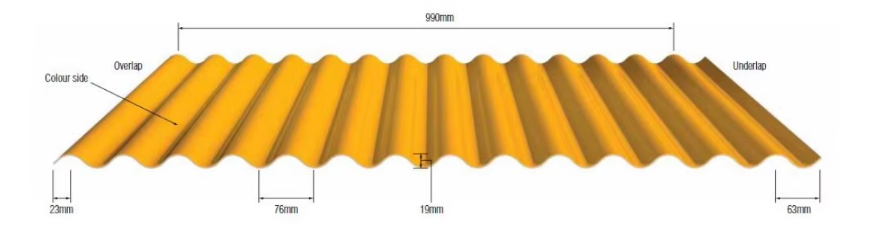

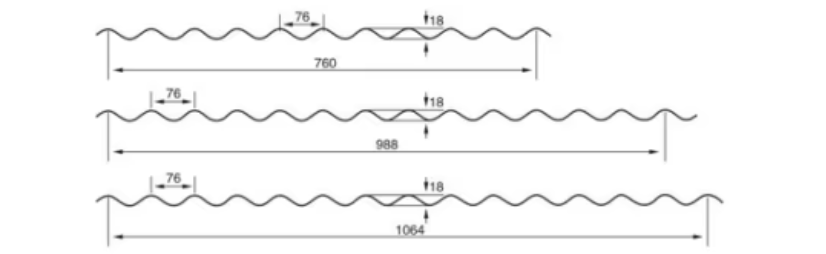

The equipment adopts industrial computer PLC control, electric operation, automatic material cutting, automatic counting, and simple operation. Only a few operators are needed to monitor and maintain the equipment, reducing labor costs.Theres some profile drawings for you reference:

Product Attributes :

Parameter and

PerformanceSuitable materialPPGI, GI, Nano film coated plate, Aluminium etcMaterial thickness0.3-0.8mmMain components5T decoiler, Roll forming machine, PLC control system, Hydraulic station, Receiving tableProduction speed0-20m/min( speed adjustable)FeatureMain frame:350-500H beam SteelPLC: Delta or Siemens (or as your request)Touch screen langauge: English/Chinese/as your requestRoller material: high grade 45# steel with hard chrome coatedShaft material: 45# steel, solidCutting: Hydraulic cutting systemThe unique feed inlet design can protect the coil paint surface and prolong the service life of roof tiles.

The cooling system on the hydraulic station can avoid overheat of hydraulic oil after long-time operate, ensure provide enough power.Advantage:

1.More than 15 years’ experience, our products has been exported to more than 150 countries all over the world.

2.We supply manufacturing, design, installation, after-sales and other services.

3.Our annual production capacity: only for cold roll forming equipment: 30-200sets / year.Products Display: