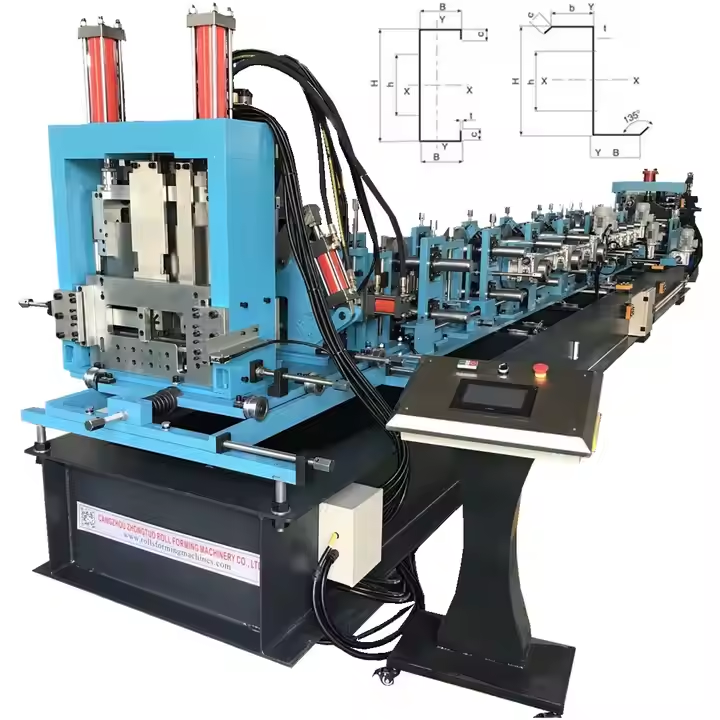

High speed CZ Purlin Roll forming Machine

The High speed CZ Purlin Roll forming Machine, a paragon of automated roll forming technology, is meticulously engineered for the rapid and efficient production of C and Z-shaped purlins crucial to steel structures and roofing applications. This state-of-the-art equipment integrates precision engineering with blazingly fast processing capabilities, utilizing advanced servo controls and high-precision rollers to deftly shape, cut, and punch metal sheets into exact profiles, all while minimizing material waste.

Fitted with an intuitive quick-change die system and sophisticated control software, it allows for smooth and swift shifts between C and Z profile production, eradicating time-intensive manual adjustments and enhancing production flexibility for a multitude of construction projects.

Advantages of High speed CZ Purlin Roll forming Machine

Beyond its remarkable operational flexibility, the High speed CZ Purlin Roll forming Machine is designed with reliability and efficiency at its core. Its sturdy build, composed of a durable frame and top-notch components, endures continuous operation, thereby reducing maintenance requirements and downtime. Automated quality control sensors embedded within the system ensure that each purlin adheres to stringent industry standards. Additionally, the automation of repetitive tasks significantly cuts down on labor costs and expedites production schedules.

Capable of processing a broad spectrum of steel thicknesses, from thin-gauge materials for residential roofing to heavy-duty sheets for industrial structures, this machine streamlines workflow, maximizes material usage, and reduces energy consumption, making it an indispensable and eco-friendly investment for construction and steel manufacturing enterprises looking to enhance productivity and maintain exceptional performance.

Main roll forming system

Main forming: 18 stations forming (inside 1 station for forming flange, 87-95 degree adjustable), 13 stations CZ change mould, turnover 180 degree to finish the change. Changing the Specification size by means of an electric button.

Rib forming: Straight rib.

Straighten: 10 rollers CZ special-use double axis straightening and 4 rollers

Double axis straightening, total 2 straightening units.

Guiding and sending: Driven by up and down gears.