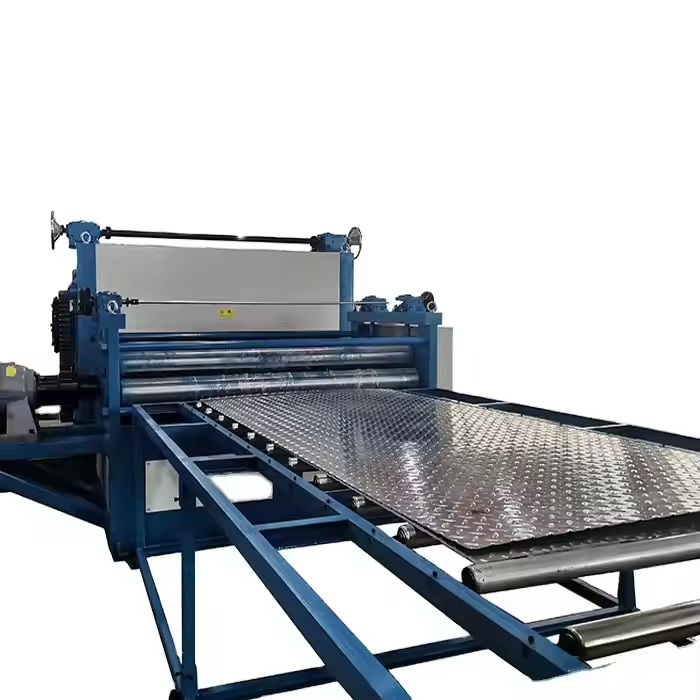

Working flow of embossing machine

Feeding table– Embossing Machine—Leveling Device- Run out table

https://www.youtube.com/watch?v=-uUnvMZVEWk

Introduction of Embossing Machine

The ZTRFM metal embossing machine deeply relies on the principles of physical deformation science, implementing controlled plastic deformation processing on metal materials through a precise mechanical force transmission system. Driven by preset parameters, its mechanical device accurately shapes metal sheets into high-value-added products with complex designed textures. The core technology relies on the high hardness and wear resistance of cemented carbide molds, combined with a micro-scale pressure feedback control module, ensuring that every embossing process achieves extreme detail reduction and guarantees the clarity and consistency of patterns.

Main parameters of embossing machine

| Embossing roller | ø440*1150 |

| Material of embossing roller: | 60CrMnMo |

| Hardness of embossing roller surface: | HRC 58~62 |

| Depth of hardness surface: | 5-10mm |

| Embossing thickness adjusted through the dial | |

| Bearing box: | 400*400*160mm . |

| Driving: | 11kw AC motor,reducer |

| Pressure mode: | hydraulic system, ø150 oil cylinder 2pcs Closed shields, safety devices. Emergency stop switch |

Structural Design and Performance Advantages

– Upgraded core components: The embossing rollers are made of alloy forged steel and treated with medium-frequency quenching (HRC55-58), significantly enhancing surface hardness and fatigue resistance, and effectively extending the service life of the equipment;

– Drive and frame innovation: Equipped with a variable frequency speed regulation system, which can dynamically adjust the processing rate according to material characteristics; the solid steel arch frame structural design, compared with traditional square tube welding technology, has stronger structural rigidity, maintaining extremely low deformation rate under high-pressure operations to ensure the stability and high precision of the embossing process.

Multi-scenario Applications and Technical Extensibility

This equipment breaks the boundaries of traditional metal processing, not only widely used in artistic processing for architectural decoration, furniture hardware, and other fields, but also realizes mass production of unique textures in automotive interior customization, balancing aesthetic value and tactile optimization; in the field of aerospace precision component manufacturing, its precision embossing technology can achieve processing of complex functional surface structures to meet strict engineering mechanics and durability standards. In addition, the equipment supports modular roller replacement—customers can either commission the customization of exclusive embossing rollers or achieve localized production based on provided engineering drawings, greatly enhancing processing flexibility.

Recommend related machine