Work flow of Double Layer Ag and R Panel Roll Forming Machine

https://www.youtube.com/watch?v=i94pUN77v9k

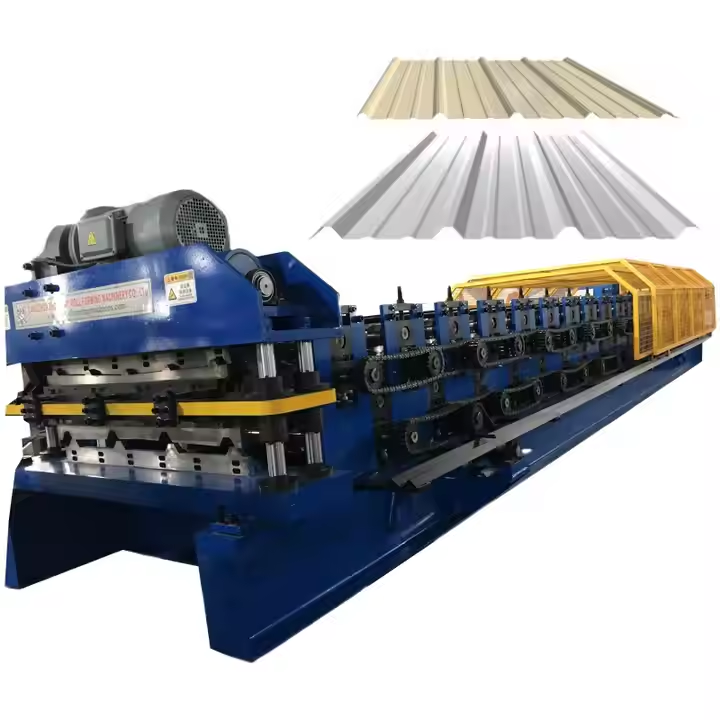

Introduction of Double Layer Ag and R Panel Roll Forming Machine Hot Sale in USA

The double layer roof sheet roll forming machine is engineered to produce two distinct profile roof sheets simultaneously on a single unit, and it has gained significant popularity in the American market. The upper layer of this advanced machine is specifically configured to manufacture AG panels, while the lower layer is designed for the production of R panels. Setting itself apart from other conventional double layer machines, this model incorporates motor shearing technology, replacing the traditional hydraulic shearing mechanism.

This machine boasts the following notable advantages:

Enhanced Speed Performance: With an adjustable speed range of 0-30 meters per minute, it operates at a rate that is twice as fast as standard design models. The utilization of a Servo motor for the main drive system plays a pivotal role in achieving this elevated speed. Additionally, the transition from hydraulic cutting to electric motor cutting further optimizes the overall production efficiency.

Superior Shearing Efficiency: When compared to hydraulic shearing, motor shearing offers a significant edge in terms of speed. Moreover, motor shearing remains unaffected by temperature fluctuations. In contrast, hydraulic shearing relies on hydraulic oil for power transmission. As a result, extreme cold or heat conditions can cause variations in the viscosity of the hydraulic oil, leading to a decrease in shearing force and inconsistent performance.

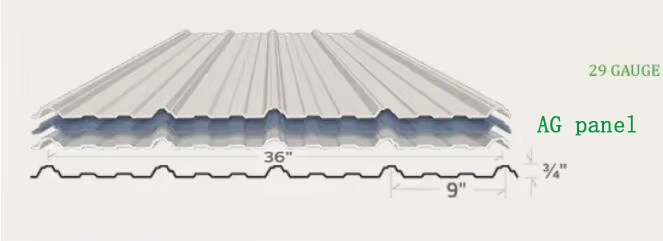

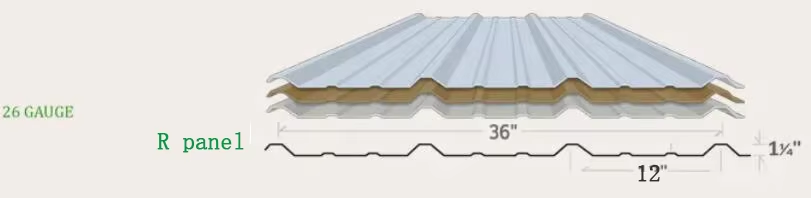

Two profile drawings of Ag and R Panel

Main parameter of Ag and R Panel Roll Forming Machine Hot Sale in USA

| Main frame | 350mm H beam structure | |||

| Material of rollers | High grade 45 high quality steel by CNC machining and hard chrome coating | |||

| Forming stations | 19 stations + 19 stations | |||

| Diameter of shafts | 80mm solid(Guaranteed) | |||

| Material of shafts | High grade 45#,with heat treatment | |||

| Forming speed | About 0-30m/min | |||

| Voltage | 220V/50HZ/3P | |||

| Transmission way | By double chains | |||

| Main motor | Servo motor 5.5kw,Yaskawa | |||

| Cutting blade material | Cr12Mov quenched treatment to improve hardness | |||

| Cutting type | Electric cutting | |||

| Driving method | By motor,5.5 kw | |||

| Cover | Whole cover for roll former,without cutter.2 parts can slide side to side easily. | |||

Recommend related machine