Work flow of CZ purlin machine

https://www.youtube.com/watch?v=zTjb1qCgnrY

Introduction of our machine

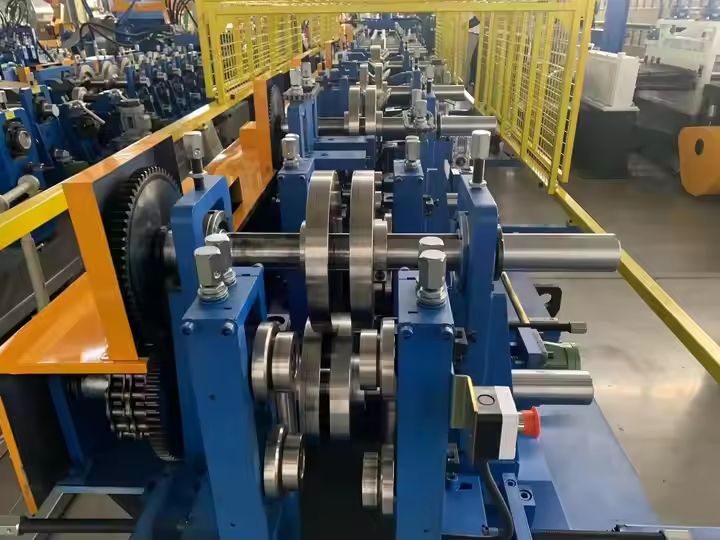

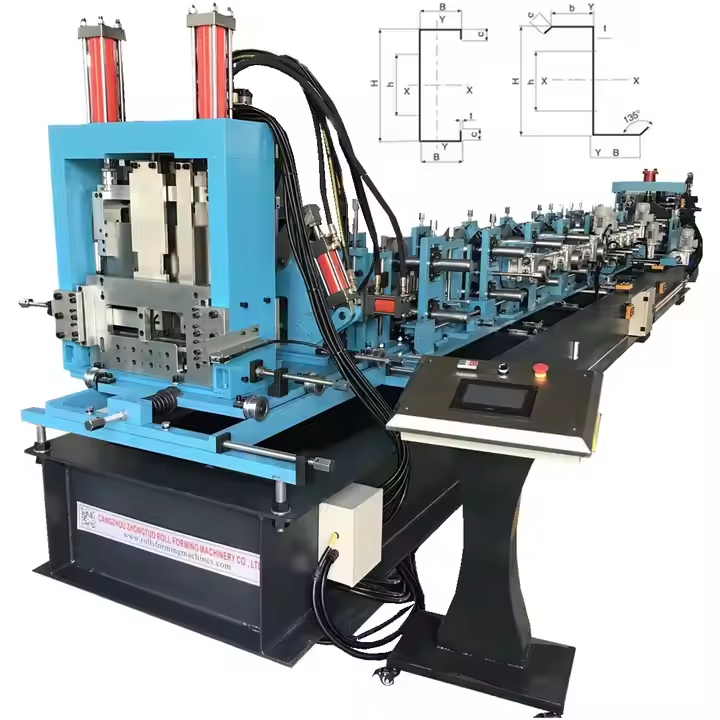

As industrialization advances at an unprecedented pace, the mechanical manufacturing sector’s demand for high – quality structural components continues to surge. In response, the CZ Purlin Machine has emerged as a revolutionary piece of equipment, expertly engineered to meet the exacting standards of modern manufacturing.

This state – of – the – art machine leverages cutting – edge technology and sophisticated design principles. Its advanced CNC control system ensures unparalleled accuracy in the production of CZ purlins, guaranteeing dimensional consistency within tight tolerances. The integration of a high – efficiency automated worktable and intelligent robotic arms not only streamlines the manufacturing process but also significantly reduces human – error, thereby enhancing overall productivity.

Built with high – strength materials and manufactured using advanced fabrication techniques, the CZ Purlin Machine boasts remarkable reliability and durability. It can endure extended periods of heavy – duty operation, maintaining peak performance whether engaged in large – scale production runs or specialized, small – batch customized of CZ purlins.

Safety is a paramount feature of the CZ Purlin Machine. Multiple layers of safety protocols, including emergency stop mechanisms, protective enclosures, and real – time safety sensors, safeguard operators. Moreover, its intelligent monitoring system constantly assesses the machine’s operational status, promptly identifying and resolving potential issues to ensure uninterrupted production.

In essence, the CZ Purlin Machine represents a stable and efficient mechanical manufacturing solution. It meets the contemporary industry’s demand for top – quality products, offering a reliable, safe, and productive means of producing CZ purlins that are essential for a wide range of construction and industrial applications.

The main parameters of the machine

|

Formed Material

|

Material yield strength: Just standard steel G350 or similar

|

Thickness:1 to 3.5 mm (standard)

|

||

|

profile

|

size

|

80-350mm (it can be adjusted automatically )

|

||

|

Changing sizes

|

Automatically by PLC

|

|||

|

Voltage

|

480V 60Hz 3Phase

|

As your requirement

|

||

|

Control system

|

Electric Cabinet

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.CAD drawing input

|

|||

|

Forming Speed

|

35 m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Advantages of CZP purlin machine

1. Tool-free Shearing Mechanism: The metal roll forming system eliminates the need for cutter replacement during shearing operations, enabling continuous production without downtime.

2. Rapid Model Transition: It supports specification switching within 3 minutes, optimizing production adaptability for diverse project requirements.

3. Precision Adjustment Capability: The web, flange, and flange edge dimensions can be fine-tuned in millimeter increments, ensuring customizable fabrication to strict tolerances.

4. Integrated CZ Cold-Forming System: As a three-step C/Z model conversion unit, this cold-rolling equipment enables efficient switching between CZ purlin production.

Also referred to as the CZ Conversion Roll Forming Machine or CZ Purlin machine, this system integrates C and Z purlin manufacturing into a unified platform. Driven by PLC computer control, it achieves high-automation purlin forming, allowing seamless switching between C/Z specifications without manual roller changes. This innovation fundamentally transforms the traditional practice of using separate machines for C and Z purlins, delivering substantial cost savings in equipment investment and factory floor space. The fully automated production process—from material feeding to final forming—eliminates the need for roller replacement, setting a new benchmark for efficiency in steel structure fabrication.

Recommend related machine