Below is a work flow video for you to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Main features:

1.Endless changeover:

The size automatically adjustment c z purlin roll forming machine adopts infinite changeover technology, which can be adjusted in millimeters within the specification range, supporting the production of standard and non-standard plate shapes without the need to replace molds or cutting heads, greatly improving production flexibility and efficiency.

2.Quick changeover:

The device can complete the changeover operation in a short period of time, usually only a few minutes to a few minutes, greatly saving time and labor costs.

3.High precision control:

Through PLC system control, ensure the precise size of the produced purlins to meet various building requirements.

4.High degree of automation:

The equipment is fully automated from loading to forming, shearing, punching, and other processes, with simple operation and suitable for large-scale production.

Product Description:

Zhongtuo roll forming equipment can replace outdated rollformers that hold your production with their lengthy changeover times. It can also be matched with your existing pierce and cut-off equipment to minimize cost.

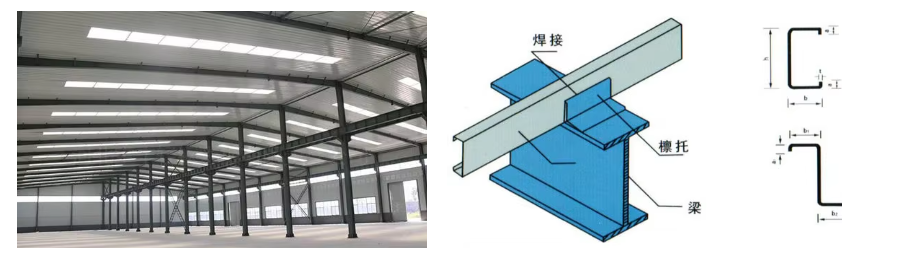

The size automatically adjustment c z purlin roll forming machine is an efficient and automated steel processing equipment, mainly used for producing C-shaped and Z-shaped steel purlins. This device integrates multiple functions, including automatic loading, leveling, punching, forming, and cutting, with easy operation and high production efficiency. Widely used in the main load-bearing structures of large and medium-sized industrial and civil buildings. Due to its efficient and precise production capacity, it is particularly suitable for construction projects that require a large number of C-shaped and Z-shaped steel purlins. In addition, the equipment is also suitable for various steel structure projects, such as factories, warehouses, bridges, etc.

Packing list:

|

No.

|

Name

|

Unit

|

Quantity

|

Remark

|

|

Part 1

|

3T decoiler

|

set

|

1

|

Manual

|

|

Part 2

|

Main roll forming machine

|

set

|

1

|

High speed

|

|

Part 3

|

PLC control station

|

set

|

1

|

Mitsubishi brand

|

|

Part 4

|

Cutting system

|

set

|

1

|

Hydraulic

|

|

Part 5

|

Hydraulic station

|

Set

|

1

|

45# oil

|

|

Part 6

|

Product table

|

set

|

1

|

Regular

|