In the field of steel manufacturing and logistics, the safe transportation and storage of steel coils have always been a focus of industry attention. During transportation, steel coils are prone to problems such as scattering and deformation at the edges due to collisions, bumps, or long-term storage. This not only affects the appearance of the product, but may also lead to safety hazards. In response to this pain point, we are pleased to launch the Full Automatic Steel Coil Inner And Outer Ring Forming machine – an advanced equipment that integrates efficiency, precision, and intelligence to safeguard the safety of steel coils.

Widely applicable scenarios: full chain protection from production to logistics

• Steel production workshop: ensuring product quality

On the steel production line, steel coils need to be immediately formed into protective rings after rolling to prevent deformation during subsequent processing or transportation. This device can be seamlessly integrated into the production process, ensuring that every step of the steel coil from output to packaging remains in optimal condition, thereby improving overall product quality.

• Logistics transportation link: Ensuring transportation safety

Steel coils face various challenges during long-distance transportation, such as bumpy roads, loading and unloading collisions, etc. By using a steel coil inner and outer ring forming machine, the edges of the steel coil are effectively protected, reducing the risk of damage during transportation, ensuring the safe arrival of the product at the destination, and reducing logistics costs.

• Warehouse management: Optimize storage space

Stable stacking of steel coils is crucial in a storage environment. This device helps steel coils maintain a neat shape, facilitates efficient use of storage space, reduces storage chaos caused by coil deformation, and improves warehouse management efficiency.

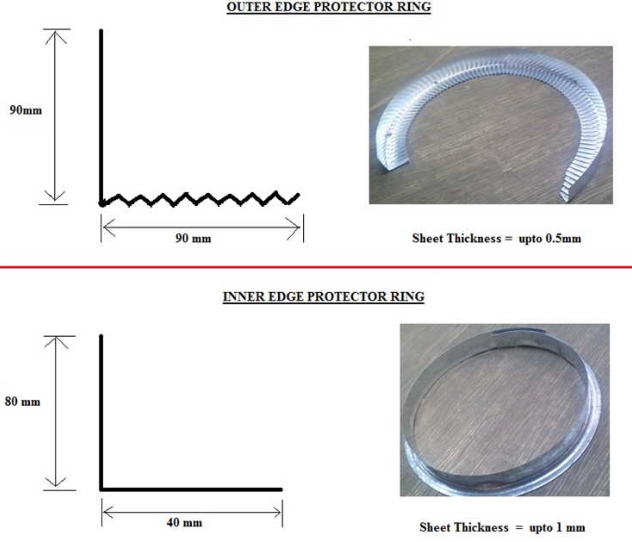

Profile drawing as below:

Product Attributes :

| 1. | Manual Uncoiler | Load Capacity: 1 ton |

| 2. | Machine Frame | Integral structure, consisting of the roll forming section, coiling section, and integral 12# channel steel welded together, with a precision-finished worktable after welding. |

| 3. | Rollers | 8 sets |

| 4. | Roller Material | Cr12MoV, hardened to HRC59-62 |

| 5. | Shaft Diameter | 55mm |

| 6. | Shaft Material | 40Cr, heat-treated |

| 7. | Wall Plate Thickness | 25mm |

| 8. | Transmission Method | Chain drive |

| 9. | Motor | 7.5kW motor |

| 10. | Drilling | Hydraulic punching, hole spacing 300-600mm ± 20mm.. |

| 11. | Rounding Device | The outer coiling rollers use a pair of roll forming rollers to create wave-like folds and round the coil. Hydraulic shears automatically cut the coil. The diameter is adjusted via a scale marking. The rollers are made of Cr12MoV wire-cut teeth. The main power is driven by a 7.5kW motor. |

| 12. | Cutting Method | Hydraulic cutting |

| 14. | Blade Material | Cr12 MOV |

| 15. | Hydraulic Power | 4kw |

| 16. | Control System | Touchscreen PLC |

| 17. | Speed | Approximately 2 pieces/minute |

Product core advantage: precise molding, safe and worry free

1. Precise size control to meet diverse needs

The Full Automatic Steel Coil Inner And Outer Ring Forming machine adopts advanced adjustable design, with the inner protective ring diameter range covering 450-600mm and the outer protective ring diameter range expanding to 980-2000mm, which can accurately adapt to different specifications of steel coils. Whether it is a small precision steel coil or a large industrial coil, perfect fit can be achieved through simple adjustment, ensuring that the steel coil maintains a stable shape during transportation and storage, effectively preventing edge scattering and deformation.

2. Efficient automation operation to improve production efficiency

The equipment adopts a fully automatic control system, which is easy to operate and greatly reduces manual intervention. The entire process from steel coil positioning to guard ring forming is smooth and efficient, significantly improving production efficiency. For example, in continuous operation scenarios, the equipment can quickly complete the formation of protective rings for multiple steel coils, reducing production downtime and creating more value for the enterprise.

3. Durable and sturdy design, suitable for harsh environments

The Full Automatic Steel Coil Inner And Outer Ring Forming machine is made of high-strength materials, with a stable structure that can withstand high temperatures, heavy loads, and vibrations in the steel production environment. Its durability design ensures that the equipment maintains stable performance even under long-term high-intensity use, reduces maintenance costs, and provides reliable production support for enterprises.