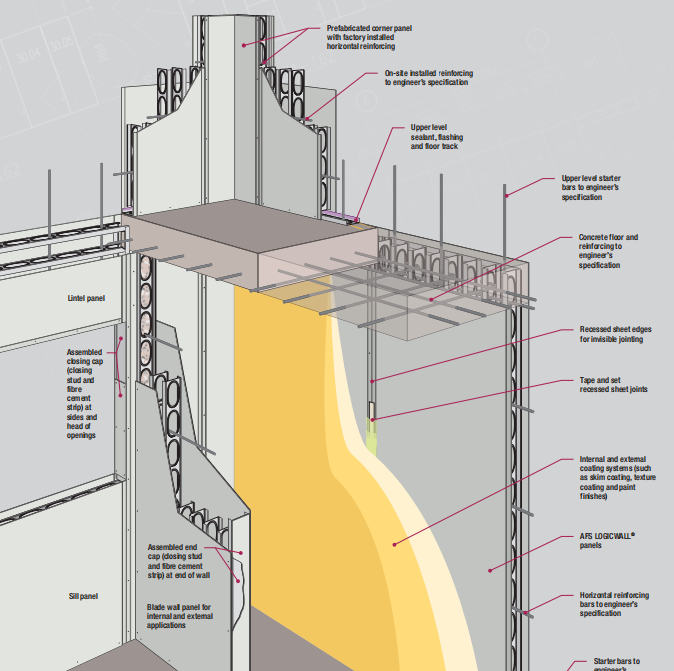

The Color Customize Metal Stud and Track C Light Keel Roll Forming Machine is a specialized equipment for producing C-section metal keels through cold rolling forming process, and its products are widely used in lightweight partition wall systems in the construction field. Based on the structural characteristics of the C-shaped keel produced by it (such as strong load-bearing capacity and flexible specifications), the main application scenarios of this equipment include:

• Indoor non load bearing partition wall:

This is the core application scenario of C-type keel machine. The C-shaped keel produced serves as the vertical main keel, which is combined with U-shaped top and ground keels to form the skeleton of light steel keel partition walls. It is widely used for indoor space separation in office buildings, hotels, factories, residential buildings, and other buildings.

• Ceiling keel frame:

Although U-shaped keels are more commonly used for ceilings, C-shaped keels can also be used as main keels or load-bearing keels in specific ceiling structures, especially suitable for additional load ceilings that require bearing additional weight (such as heavy lighting fixtures and equipment).

• Light steel villa and main structure construction:

In light steel structure buildings, C-shaped keel is a key material for constructing the wall main frame, and its strength and standardized production make it widely used in the construction of light steel villas.

Profile drawing as below:

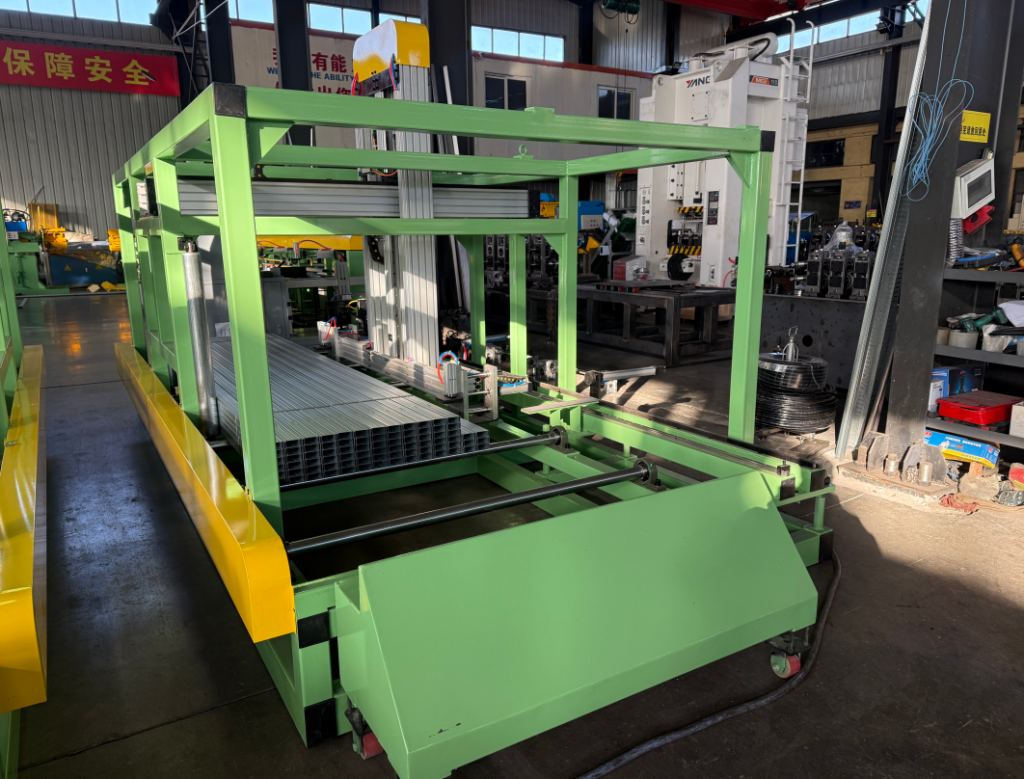

Core positioning: Cracking industry pain points and consolidating production foundation

Currently, traditional keel production equipment in the industry generally suffers from pain points such as large precision fluctuations, high energy consumption, tedious changeover, and low efficiency. Some equipment has a molding speed of only 15-20 meters per minute, a material loss rate of over 8%, and product straightness and size errors are difficult to meet high-end engineering needs. Color Customize Metal Stud and Track C Light Keel Roll Forming Machine focuses on the core pain points of the industry, with “high precision, high efficiency, high stability, and low energy consumption” as its core positioning. Through technological innovation and process optimization, it has achieved a full process upgrade from raw material processing to finished product molding, providing solid guarantees for enterprises to reduce operating costs and improve product competitiveness. It is a key equipment for the transformation of traditional production modes to modernization and intelligence.

Machine features:

1.High precision and stability

2.Efficient Production and Automation

3.Multi functionality and flexibility

4.Improve construction quality and efficiency

5.Industry adaptation and service guarantee

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.7-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gear transmission

|

|||

|

Dimension(L*W*H)

|

7800*800*1200(customize)

|

|||

|

Weight

|

About 4.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW*2 sets

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

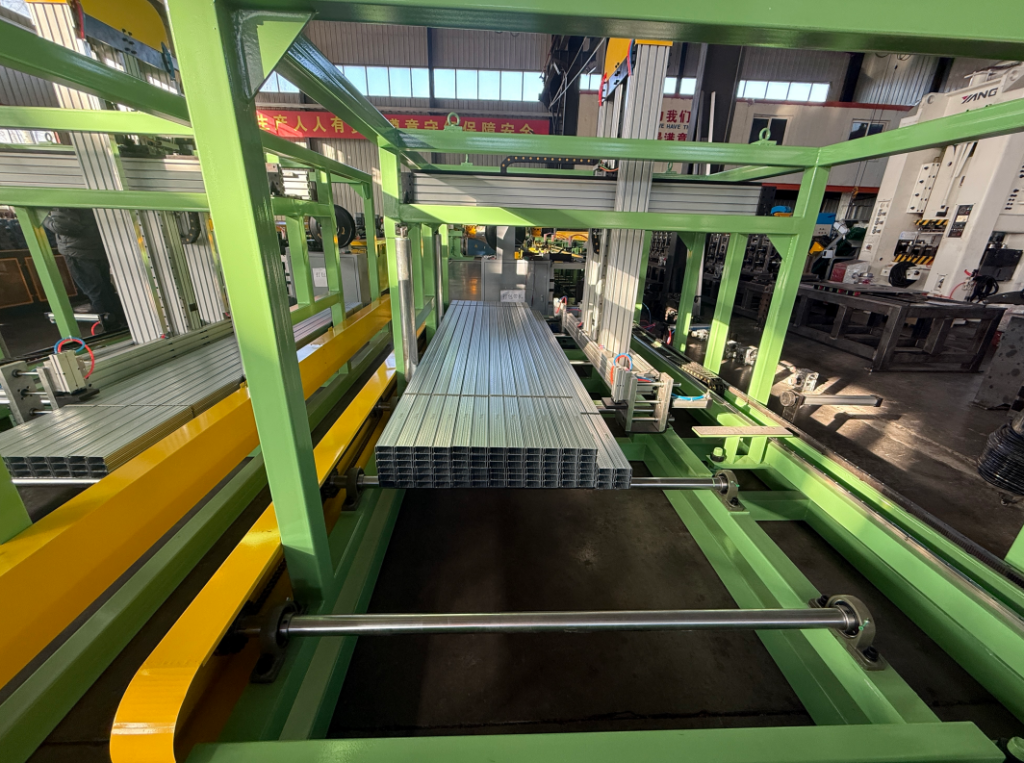

18.Forming Speed

|

40-100m/min(customized)

|

Different speed designs for options.

|

||

Core advantage: Multi dimensional technological breakthroughs, leading industry upgrading

The core competitiveness of the Color Customize Metal Stud and Track C Light Keel Roll Forming Machine in comprehensive technological innovation and detail polishing, with key advantages concentrated in the following four dimensions:

1. High precision molding ensures engineering quality

Adopting German servo drive system and high-precision laser correction technology, combined with multi pass continuous forming process, the product size error is strictly controlled within ± 0.1mm, and the straightness error is ≤± 0.2mm, which is more than 30% higher than the industry standard. The core component of the rolling mill is made of Cr12MoV alloy steel, which has a hardness of HRC58-62 after vacuum quenching treatment. It is wear-resistant and wear-resistant, ensuring the stability of forming accuracy under long-term continuous operation. The bending strength of the C-type keel produced reaches 345MPa, fully complying with the national standard GB/T 6725-2017. It can effectively avoid engineering hazards such as wall tilting and ceiling deformation, and is suitable for harsh scenarios such as super high-rise buildings and commercial complexes.

2. Efficient and energy-saving operation, improving production efficiency

By optimizing the transmission structure and intelligent speed control system, the forming speed of the equipment has been increased to 40 meters per minute, and some models can reach 120 meters per minute without punching, which is more than three times more efficient than traditional equipment. Integrating the full process automation functions of unwinding, leveling, forming, cutting, and stacking, reducing manual intervention by 70%, and reducing the number of single shift operators from 3 to 1, significantly reducing labor costs. At the same time, the energy consumption is reduced by 25% compared to traditional equipment, and the material utilization rate is increased to over 92%. A single ton of steel can produce an additional 12 meters of keel, saving over 300000 yuan in raw material costs annually, achieving a dual improvement in production capacity and efficiency.

3. Flexible adaptation to scenarios, reducing investment costs

Adopting a modular design concept and supporting rapid changeover of multiple specifications, mold replacement and parameter debugging can be completed within 15-30 minutes. It can produce various C-type keels with a thickness of 0.5-3.0mm and a width of 30-300mm, compatible with the production of more than 5 specifications of products, without the need to purchase additional equipment, greatly reducing the initial investment cost of enterprises. At the same time, it supports non-standard customization services and can develop irregular keels such as curved and wavy according to customer needs, with a minimum bending radius of 50mm. It is suitable for special decoration scenarios such as theaters, airports, subway stations, as well as new energy supporting scenarios such as photovoltaic brackets and charging pile columns.

4. Stable and durable design, reducing maintenance costs

The equipment framework is made of Q345B structural steel, which increases the overall deformation resistance by 20% and reduces the weight by 15% compared to the industry average, saving space occupied by the factory. Equipped with automatic lubrication system and remote fault warning module, real-time monitoring of equipment operation status, predicting potential faults in advance, reducing equipment failure rate from 0.8% to 0.3%, and reducing downtime by 60%. The maintenance cycle has been extended to 500 hours, and the service life of key components has reached three times the industry average. The annual maintenance cost has been reduced by 40%, providing a guarantee for the long-term stable production of enterprises.

Machine video: