Work flow of Ceiling Panel Roll Forming Machine

https://www.youtube.com/watch?v=7rTtlPS6JXc

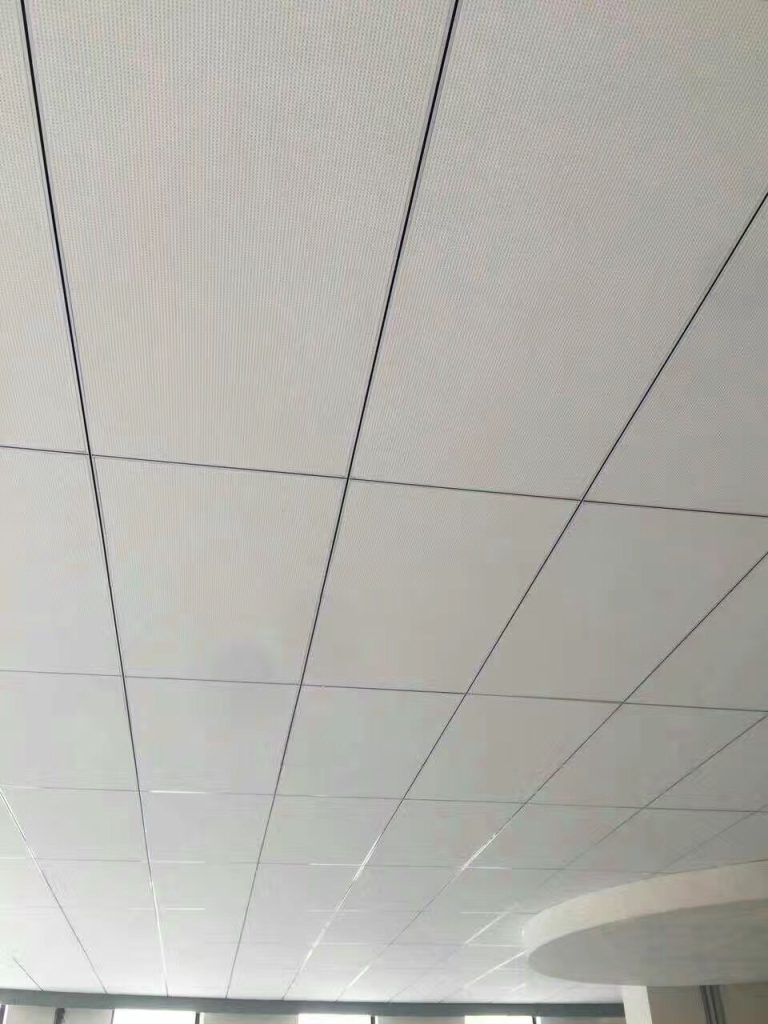

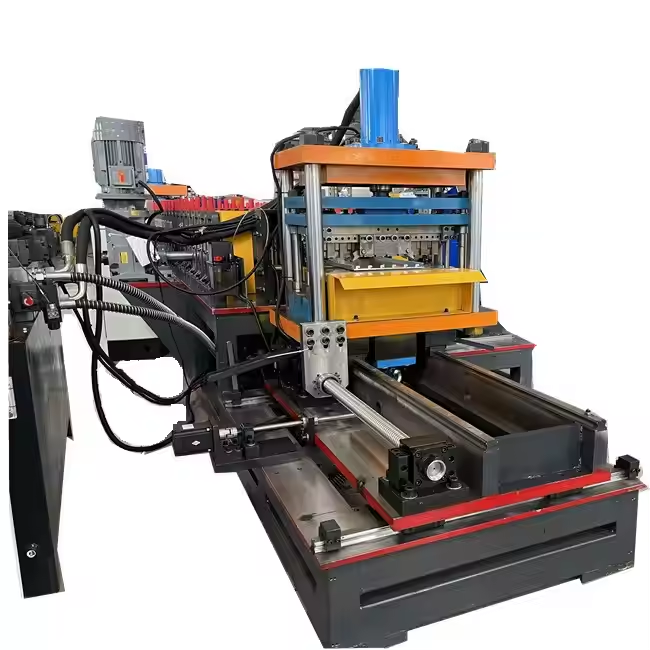

Metal ceiling panel forming machines are specialized equipment integrating mechanical design, automated control, and material processing technology. They are designed for efficient production of various metal ceiling panels and play a crucial role in the architectural decoration and building materials industry. Using metal coils (such as galvanized steel sheets, aluminum alloy sheets, stainless steel sheets, etc.) as raw materials, they transform flat coils into ceiling panels with specific structures, sizes, and decorative effects through a series of continuous, high-precision processing procedures, meeting the decoration needs of different scenarios.

I. Core Working Principles and Process Flow

The forming process of metal ceiling panels is an efficient transformation from “coil → continuous processing → finished panels”, relying on roll forming technology and coordinated by an automated control system to achieve a full-process synergy:

1. Raw material loading and leveling: Metal coils are smoothly released by the uncoiler and enter the leveling mechanism. The leveling roller group adjusts the pressure precisely to eliminate bending and wrinkles generated during the rolling and storage of the coils, ensuring the sheet surface is flat and the stress is uniform when entering the next process, laying the foundation for subsequent forming accuracy.

2. Roll forming: This is the “core process” of the equipment. According to the cross-sectional shape of the ceiling panel (such as U-shaped, V-shaped, square, special-shaped, etc.), multiple sets of upper and lower symmetric roller dies gradually roll the sheet in a preset order. Each set of rollers is responsible for a slight shape deformation. After the continuous action of dozens of sets of rollers, the sheet gradually forms the designed cross-sectional structure. During this process, both the shape accuracy is ensured and the material is prevented from cracking or wrinkling due to excessive instantaneous deformation.

3. Auxiliary processing (configured as needed):

– Punching/notching: Some ceiling panels need to reserve installation holes, ventilation holes, or decorative notches. The equipment can integrate a CNC punching mechanism, which drives the punch through a servo motor to accurately punch holes at specified positions. The hole diameter and pitch can be flexibly adjusted through programs.

– Embossing/texture processing: To enhance decorativeness, some equipment is equipped with embossing rollers, which can press wood grain, stone grain, geometric patterns, and other textures on the sheet surface to enhance the visual effect.

4. Fixed-length cutting: The formed continuous sheet enters the cutting mechanism. A flying saw or hydraulic cutting knife controlled by a servo motor performs precise cutting according to the preset length (such as 3 meters, 6 meters, etc.), ensuring that each finished sheet has a consistent length with an error controlled within ±1mm.

5. Finished product conveying and stacking: The cut sheets are conveyed to the stacker via a conveyor roller table and automatically stacked into neat piles, facilitating subsequent packaging, storage, and transportation.

Main parameters of the machine

|

1..Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive way

|

gear

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 8T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

30m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

II. Core Advantages and Technical Features of the Equipment

1. Ultra-high automation and intelligence

Modern metal ceiling panel forming machines generally carry a PLC control system (Programmable Logic Controller) with a touchscreen operation interface. Operators can intuitively set parameters such as sheet length, thickness, and forming speed, and the equipment automatically memorizes and executes the program. Some high-end models also support CAD drawing import to directly generate processing parameters, reducing manual debugging time. Meanwhile, the system has a real-time monitoring function, which can automatically detect problems such as material deviation, abnormal thickness, and mold wear, trigger an alarm and stop the machine, reducing the rejection rate.

2. Dual guarantee of precision and stability

– In terms of mechanical structure, the roller dies are made of high-strength alloy materials (such as Cr12MoV) and undergo precision grinding, with a surface roughness as low as Ra0.8μm, ensuring no scratches or indentations on the sheet surface;

– The transmission system adopts a combination of servo motor and ball screw to ensure precise control of roller speed and feed rate. The forming tolerance can be controlled within ±0.3mm, meeting the requirements of splicing tightness and flatness during ceiling installation;

– The equipment frame adopts an integral welding structure, which eliminates internal stress through aging treatment, resulting in low vibration during operation and avoiding the impact of machine body deformation on processing accuracy.

3. Strong flexibility and compatibility

One equipment can produce various specifications of ceiling panels by replacing roller dies and adjusting parameters:

– Size range: The width can cover 50mm-600mm, the thickness can adapt to 0.3mm-1.2mm (adjusted according to material strength), and the length can be set arbitrarily;

– Diverse shapes: It can produce not only conventional products such as flat panels, strip panels, and square buckle panels but also custom-shaped ceiling panels such as arc-shaped, wave-shaped, and three-dimensional relief panels, meeting personalized decoration designs.

4. High efficiency, energy saving, and low loss

– In continuous production mode, the equipment speed can reach 8-30 meters per minute, with a daily output of thousands of square meters, far exceeding the efficiency of traditional manual processing;

– High material utilization: Roll forming is a cold processing process with no material loss due to combustion or melting. With precise cutting technology, the proportion of leftover materials can be controlled within 3%;

– Energy-saving design: Some models adopt variable frequency motors, which can automatically adjust the speed according to the production load, reducing standby energy consumption; heating systems (such as auxiliary equipment for coating drying) use infrared heating, with thermal efficiency increased by more than 30% compared to traditional resistance heating.

Application Scenario of ceiling panel

Recommend related machine