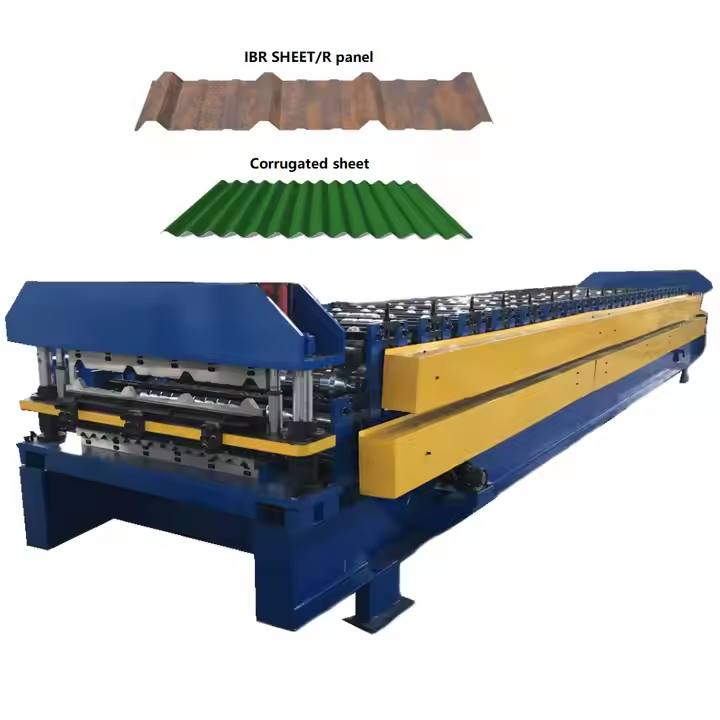

Aluminum metal double layer roof sheet machine

An aluminum metal double layer roof sheet machine is available in multiple variants, each engineered to collaborate seamlessly with corrugated sheets, IBR sheets, or glazed tile sheets. These machines leverage advanced manufacturing techniques to produce high – quality roofing tile sheets, meticulously crafted to meet the diverse demands of modern construction projects.

These roofing tile sheets find extensive application across a broad spectrum of structures. In industrial factories, they provide robust protection against harsh working conditions, offering excellent resistance to wear, tear, and environmental factors. For civilian buildings, including residential homes and commercial complexes, they combine functionality with aesthetic appeal, enhancing the visual charm of the structure while ensuring reliable weatherproofing. Additionally, they serve as essential roof boards for attached structures, providing stable and durable roofing solutions. With their attractive appearance, long – lasting durability, and superior performance, these sheets have become a preferred choice for architects, builders, and property owners seeking both functionality and style in their roofing systems.

Here is an aluminum metal double layer roof sheet machine exported to Italy.

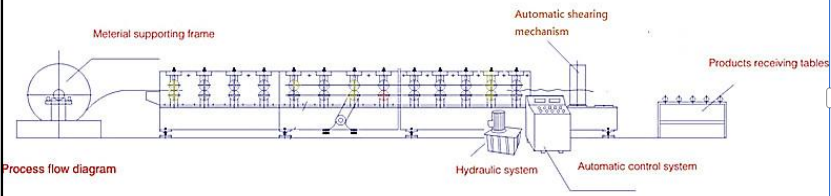

Working flow of double layer roof sheet machine

Uncoiling→Feeding material into machine→Roll forming machine→Auto cutting→Products receiving table

The main roll forming machine

Machine frame:350mm Hbeam structure,with 18mmwelded steel middle support plate.

Material of rollers: High grade 45# forged steel, surface hardchromium plating,avoid scratching paint of raw material andgetting rusty.

Forming stations:Upperlayer 16 rows

Lower layer 18 rowsDiameter of shafts:Ф80mm solid

Material of shafts:High grade 45#,with heat treatmentForming speed:upper layer 3-4m/min

Lower layer 0-12m/minvoltage:415V/50HZ/3P (as requested)eTransmission way: By 1 inch chain

Main motor:5.5kW(servo motor)

Cutting blade material:Gcr12 quenched treatment

Cutting type:hydraulic post cutting

cutting system

Recommended machine