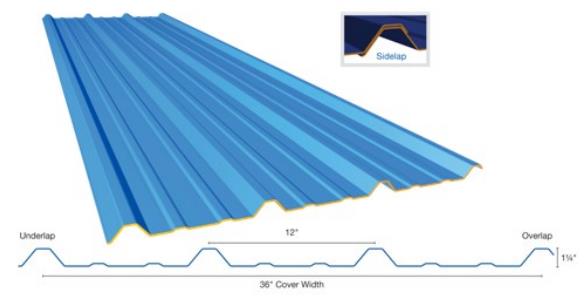

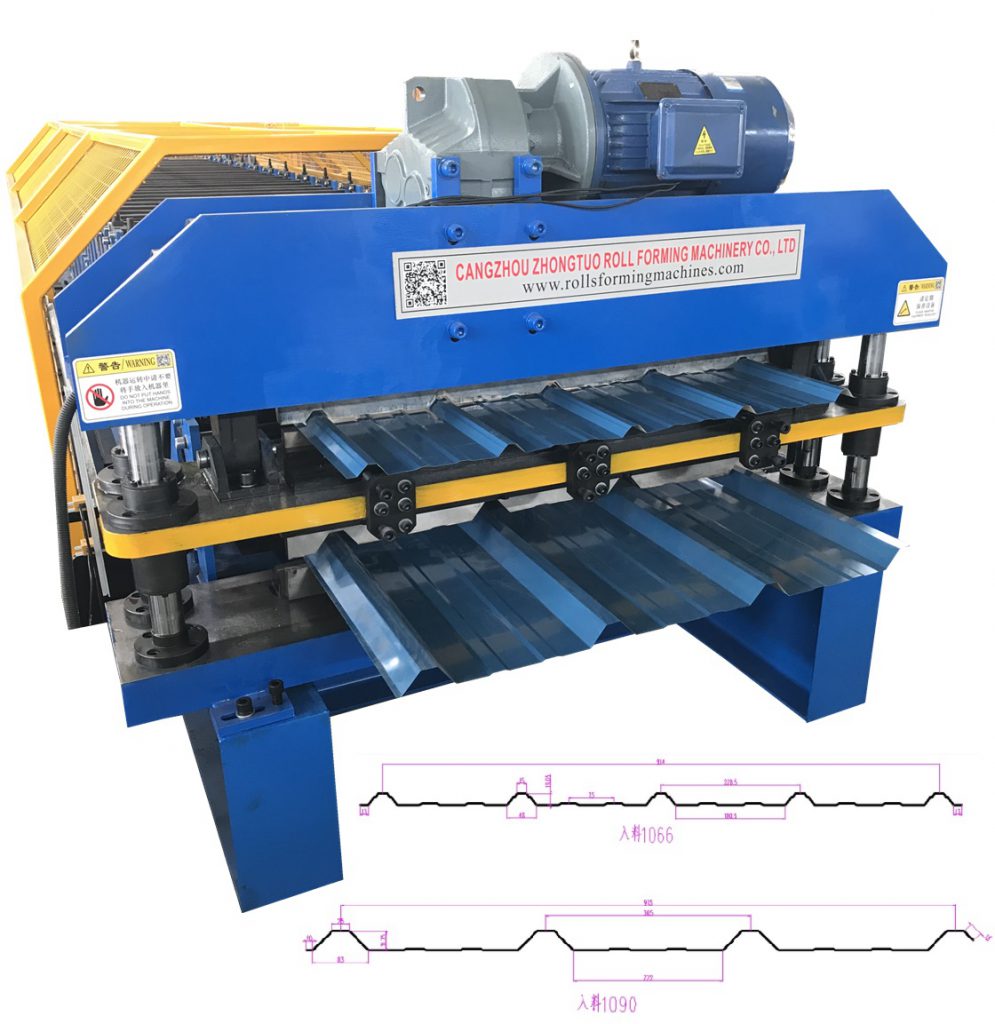

AG Panel Roll Forming Machine

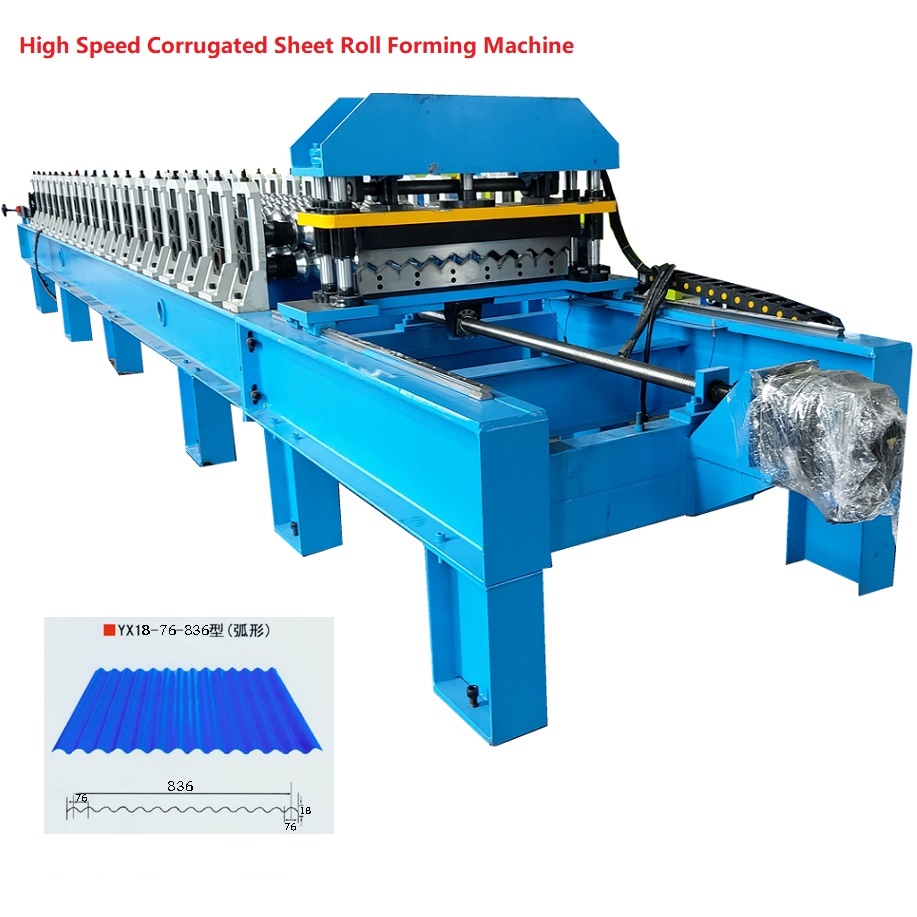

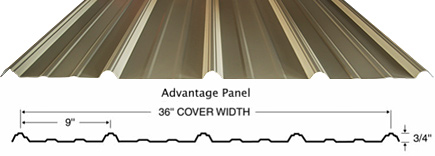

USA 3/4” AG panel roofing sheet high speed roll forming machine

This USA 3/4” AG panel roofing sheet high speed roll forming machine is produced for USA market which is a very popular roofing sheet.There are also some other popular roofing sheets such as R panel PBR panel,we can produce all these roll forming machines for roofing sheets,and we also support customization.

The features of our USA 3/4” AG panel roofing sheet high speed roll forming machine:

1.High speed:0-30m/min

2.Transmmission:by gearbox

3.Equip with Hydraulic pre-cutter which can reduce the waste material when customer change coils.

4.Equip with hydraulic decoiler and automatic stacker to improve the high automation of the machine working,no need workers to operate.

5.Support customization.

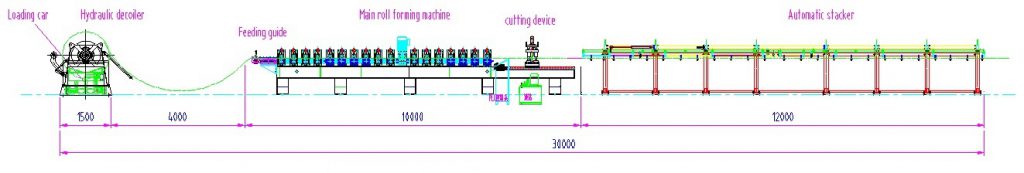

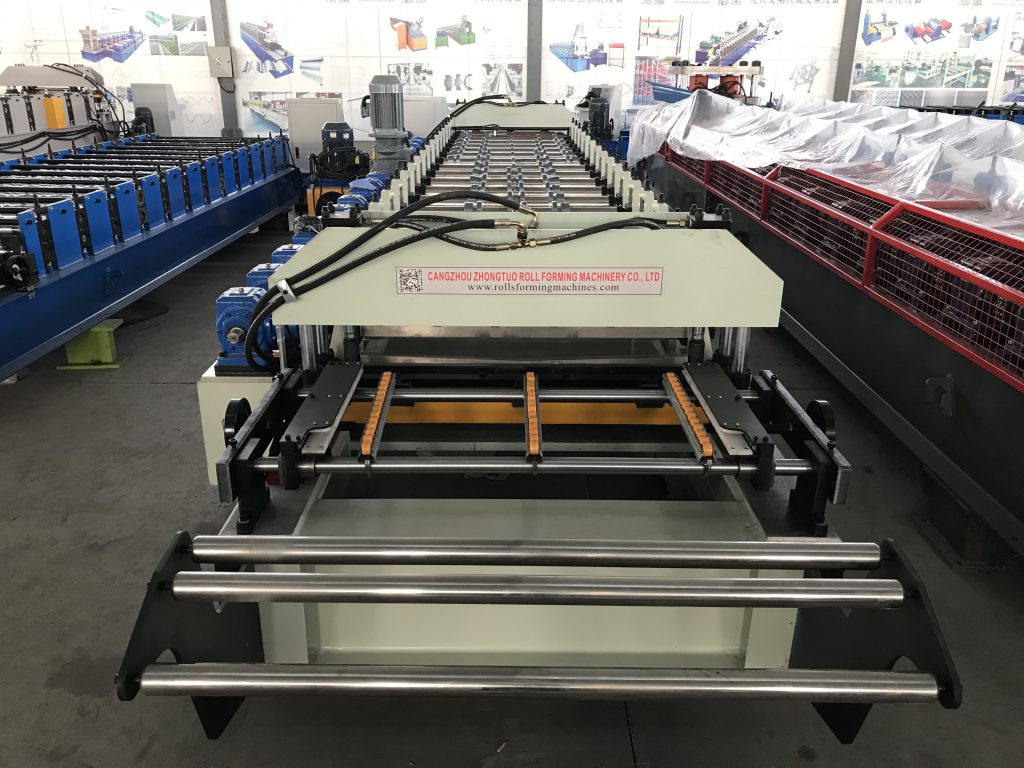

The layout of the

USA 3/4” AG panel roofing sheet high speed roll forming machine:

The technical specifications of the USA 3/4” AG panel roofing sheet high speed roll forming machine:

1.Uncoiler

- Capacity:5 tons/8 tons/10 tons,as customer’s request

- Coil width:max 1250mm,as customer’s request

- Working type:Full automatic move forward and backward,hydraulic coil core expansion.

- Motor power:3 kw+3kw

- Equip with pneumatic press arm to prevent the coil from loosing

- Equip with the braking system

- Equip with the remote control for easy operation

- Loading car for coil is optional

2.Roll forming

- Machine frame:350H steel welded,molding frame structure,diagonal bracing support

- Roller station:16 stations

- Roller material:45# steel with quenched treatment,surface chromed

- Shaft diameter:80mm,solid

- Shaft material:45# steel

- Transmission type:By gearbox

- Motor power:11kw

- Speed:0-30m/min

3.Hydraulic cutting system

- Cutting type:hydraulic pre-cutting and post cutting

- Cutting blade material:Cr 12 with quenched treatmtne

- Machine structure:4 guide posts supporter

- Power:7.5kw

- Hydraulic station equip with fan cooling system

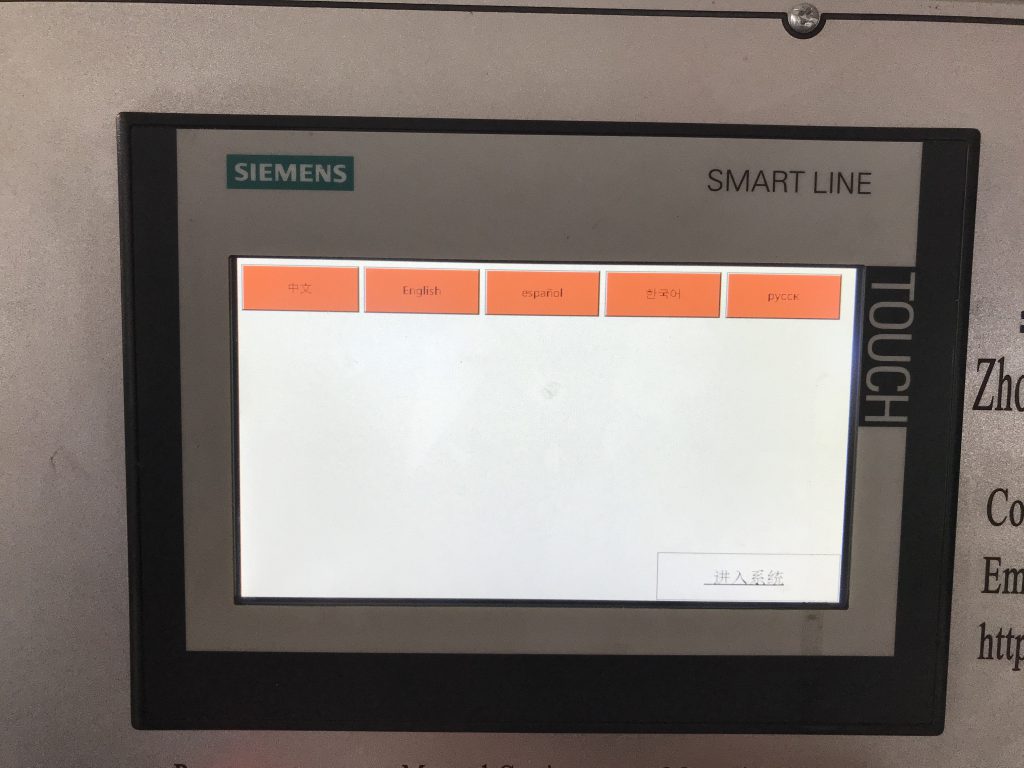

4.Control system

- Function:Control the cutting length,quantity and batch by PLC.

- PLC brand:Delta/Siemens/Schneider

- Touch screen:Delta/Siemens/Schneider

- Low pressure apparatus:Schneider

- Encoder brand:Omron

5.Auto stacker

- Function:To receive the finished product after cutting automatically

- Length:6 meters or 12 meters as customer’s request

- Working type:Pneumatic

AG panel roll forming machine Working video:

Related roll forming machine recommondation: