C Stud Shelf Diagonal Brace Roll Forming Machine For Scaffolding

In today’s rapidly developing logistics and warehousing industry, shelves serve as the core structure supporting the entire warehousing system, and their quality and performance directly affect warehousing efficiency and safety. As the key component of the shelf, the slant support of the shelf undertakes the important mission of enhancing the stability of the shelf and improving the load-bearing capacity. For this reason, we have launched the C Stud Shelf Diagonal Brace Roll Forming Machine For Scaffolding, an advanced equipment integrating efficient production, stable load bearing and intelligent control, to inject strong power into your storage business.

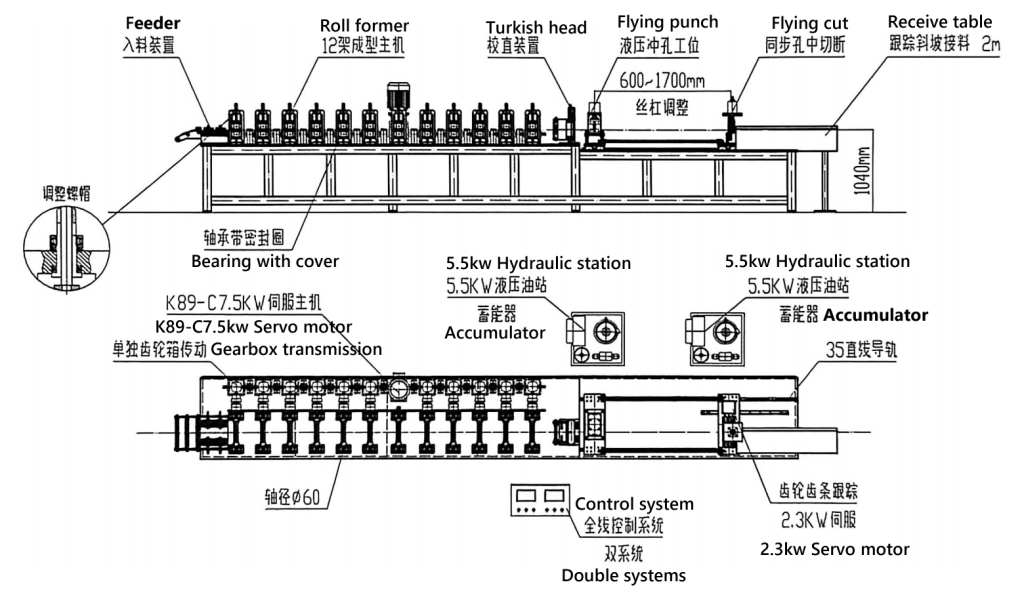

Process flow:

Application Scenarios :

• The warehousing and logistics industry: the core of supporting an efficient warehousing system

• Retail Industry: Customized Display and Space Optimization

• Manufacturing industry: Ensuring material management in production workshops

• Exhibition and Display Industry: Stable Display Shelves and Flexible Design

Finished product image:

Key Features:

1、 Efficient production, leap in production capacity

The advanced cold bending process is used to roll the metal plate continuously at room temperature to make it plastic deformation and accurately form the required slant support shape of the shelf. This process not only preserves the original strength of the metal material, but also greatly improves production efficiency. The equipment is equipped with high-performance PLC control cabinets and adopts Delta/Schneider high-precision PLC electrical control systems to achieve automation and intelligence in the production process. Operators only need to input production data through the touch screen, and the equipment can automatically complete the entire process from feeding, forming to cutting, significantly reducing manual intervention and lowering production costs.

2、 Stable load-bearing capacity, safe and worry free

The two ends of the produced slant support products are processed into rectangular connection surfaces, and are provided with fixed holes connected with the continuous holes on the rack columns. This design not only improves the stiffness of the end node, effectively solves the problem of the deformation of the traditional slant support of the shelf, but also ensures the overall stability of the shelf by locking and fixing the connecting bolts.

3、 Intelligent control, easy to operate

Equipped with advanced PLC control cabinet and touch screen operation interface, the equipment operation becomes simple and intuitive. Operators do not need to have deep mechanical knowledge, they only need to input production parameters through the touch screen, and the equipment can automatically complete production tasks. At the same time, the equipment also has a fault self diagnosis function, which can timely detect and prompt potential problems, reduce downtime, and improve production efficiency.

4. Remote monitoring and data management

By connecting to the enterprise management system, real-time collection and analysis of production data can be achieved, providing strong support for production decision-making. This intelligent operation method not only reduces the difficulty of operation, but also improves the flexibility and response speed of production.