The Full Automatic Steel Coil Inner And Outer Protective Ring Machine is a specialized equipment used for steel coil packaging. Its main function is to process steel strips into inner or outer protective rings to protect the steel coils from damage during transportation and storage. This equipment usually integrates processes such as unwinding, punching, bending, shearing, and forming to achieve automated production.

Application scenarios:

• Steel coil packaging:

Protective rings are used for the inner and outer packaging of steel coils to prevent damage during transportation and storage.

• Industrial applications:

widely used in industries such as steel and machinery manufacturing.

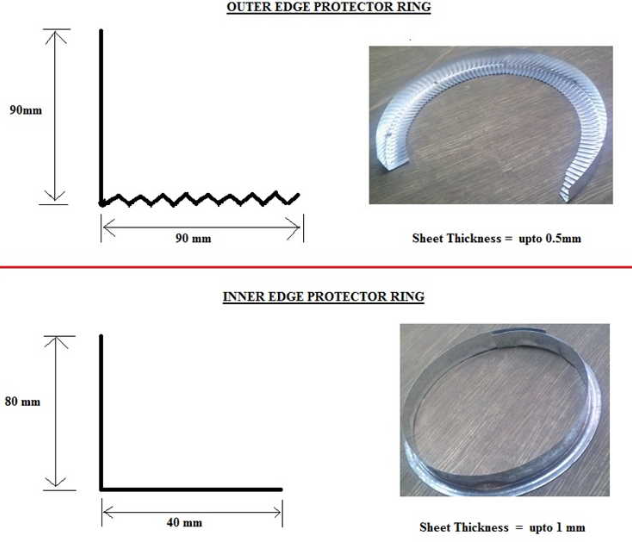

Pattern diagram:

Product Attributes :

| 1. | Manual Uncoiler | Load Capacity: 1 ton |

| 2. | Machine Frame | Integral structure, consisting of the roll forming section, coiling section, and integral 12# channel steel welded together, with a precision-finished worktable after welding. |

| 3. | Rollers | 8 sets |

| 4. | Roller Material | Cr12MoV, hardened to HRC59-62 |

| 5. | Shaft Diameter | 55mm |

| 6. | Shaft Material | 40Cr, heat-treated |

| 7. | Wall Plate Thickness | 25mm |

| 8. | Transmission Method | Chain drive |

| 9. | Motor | 7.5kW motor |

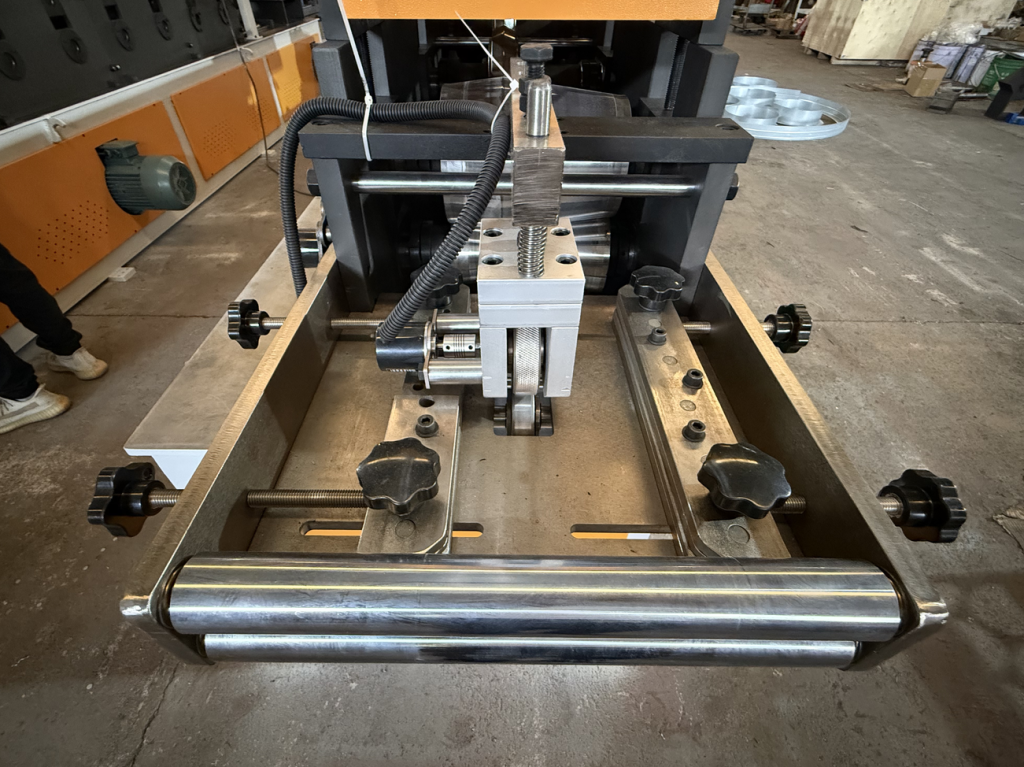

| 10. | Drilling | Hydraulic punching, hole spacing 300-600mm ± 20mm.. |

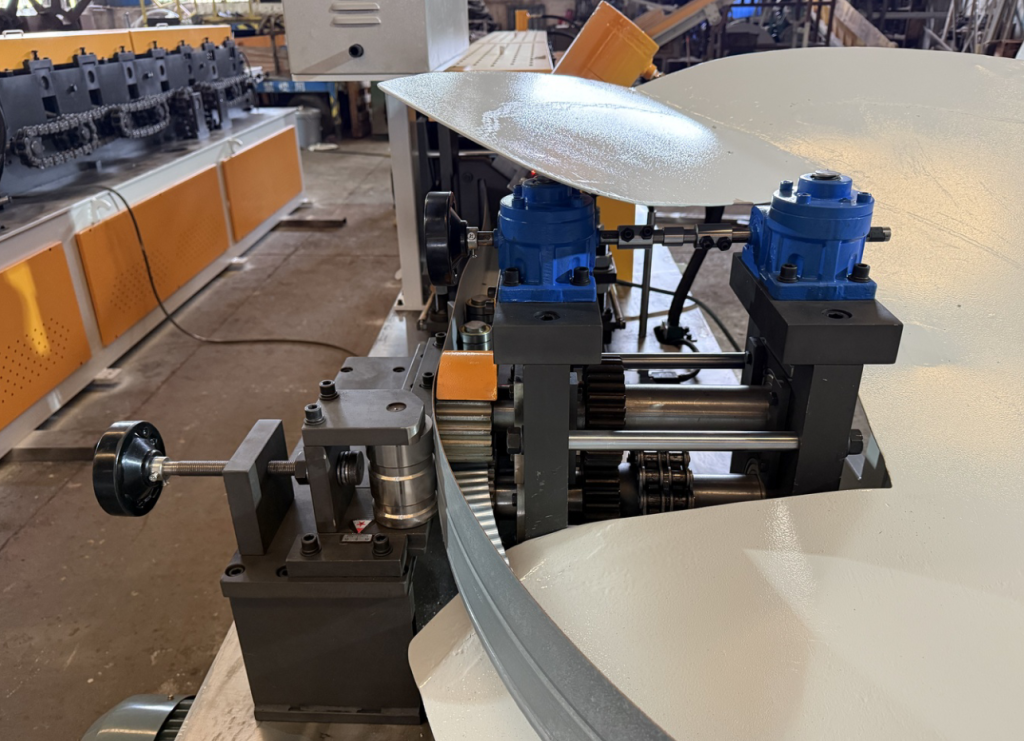

| 11. | Rounding Device | The outer coiling rollers use a pair of roll forming rollers to create wave-like folds and round the coil. Hydraulic shears automatically cut the coil. The diameter is adjusted via a scale marking. The rollers are made of Cr12MoV wire-cut teeth. The main power is driven by a 7.5kW motor. |

| 12. | Cutting Method | Hydraulic cutting |

| 14. | Blade Material | Cr12 MOV |

| 15. | Hydraulic Power | 4kw |

| 16. | Control System | Touchscreen PLC |

| 17. | Speed | Approximately 2 pieces/minute |

Key Features:

1.High level of automation and intelligence:

The equipment usually adopts PLC control system and frequency converter speed regulation to achieve fully automatic assembly line operation from unwinding, punching, bending, shearing to forming, reducing manual intervention and requiring only a small number of operators to pick up the parts at the exit; Parameter adjustments, such as cutting length and line speed, can be conveniently set through the touch screen to enhance operational flexibility.

2.Efficient production and stable performance:

The equipment design focuses on production efficiency and has a short molding cycle. For example, the molding speed of inner corner protectors can reach 3-4 pieces/minute, and the molding speed of outer corner protectors can reach 4-6 pieces/minute, which is suitable for mass production; Key components such as rollers are made of bearing steel material, with a profiled shaft diameter of 70mm, ensuring operational stability and durability, and reducing failure rates.

3.High precision molding and wide material adaptability:

The equipment can accurately control the contour range of the protective ring and adapt to the packaging requirements of different specifications of steel coils; Some models support processing of various materials, such as galvanized sheet, color coated coils, etc., to meet diverse industrial scenarios.

4.Reasonable structural design and convenient maintenance:

The equipment usually adopts a sprocket chain transmission method, with smooth transmission, reasonable power configuration (such as 7.5KW), moderate footprint (such as 8 × 2 × 1.4 meters), and easy factory layout; Standardized component design simplifies maintenance processes and reduces downtime.