In the modern warehousing and logistics system, shelves are like the skeleton that supports efficiency, while columns are the “spine” that runs through them, carrying the weight of goods, optimizing space, and ensuring operational safety. As the core load-bearing component of the shelving system, the quality of the shelving columns directly determines the stability, load-bearing capacity, and service life of the storage structure, and is a key equipment for enterprises to achieve efficient storage, cost reduction, and efficiency improvement.

Application Scenarios :

• E-commerce logistics and retail distribution field

Adjustable shelves constructed with medium-sized columns, suitable for classified storage of massive SKUs, with flexible adjustment of floor height to meet the diverse needs of clothing, 3C accessories, daily necessities, and other goods, helping to improve the efficiency of daily high order picking.

• In the food and pharmaceutical industries

Stainless steel columns and anti-corrosion treated columns can withstand humid and corrosive environments, meeting the strict requirements of clean workshops and cold chain warehouses, ensuring the safety of goods storage.

• In heavy industries such as electricity and energy

The high-level shelf supported by large cross-section heavy-duty columns can achieve three-dimensional storage of heavy components such as engines and transmissions, and can be operated mechanically with stacker cranes. The storage density is increased by more than 50% compared to traditional shelves.

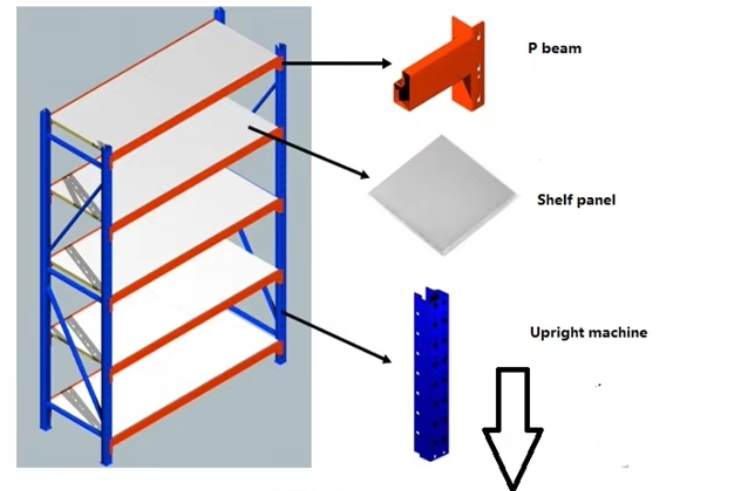

Finished product image:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-2.7mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

will give you as free

|

||

|

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

As your requirement

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

About 75T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

customized

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Key Features:

1.Graded load-bearing capacity, precise adaptation to diverse needs

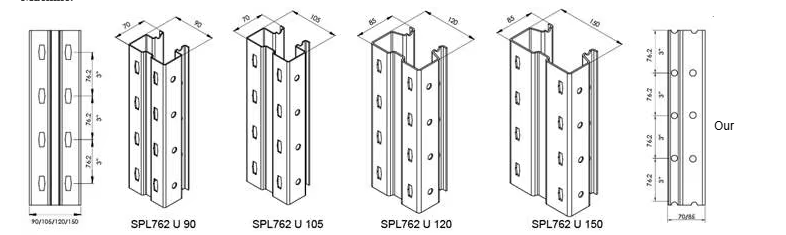

The cross-sectional size, wall thickness, and inertia distance of the column directly determine its load-bearing capacity, forming a product system that covers light, medium, and heavy scenarios. Lightweight column specifications can reach 38 × 38mm, with a single layer bearing capacity of 100-150kg, suitable for storing small and miscellaneous items; Medium sized columns are mainly available in specifications such as 50 × 30mm and 80 × 40mm, with a load-bearing range of 100-800kg, meeting the needs of industries such as electronics, food, and auto parts; The heavy-duty column adopts a large cross-sectional design ranging from 80 × 60mm to 120 × 95mm, with a single layer bearing capacity of up to 3 tons. The overall shelf bearing capacity exceeds 20 tons, making it easy to handle industrial heavy parts and bulk material storage.

2.Modular design, flexible adaptation to spatial changes

The surface of the column is pre-set with standard spacing holes, and the floor height can be freely adjusted with a step size of 75mm or 100mm. With multiple connection methods such as hook and bolt, it can be quickly assembled and disassembled, and the shelf structure can be dynamically adjusted according to the size and storage capacity of the goods. The modular component design supports later expansion and renovation. A single column can be connected in series into multiple systems through a pull rod, and the double-sided configuration can greatly improve the storage density per unit area, maximizing the use of vertical and horizontal space in the warehouse.

3.Strengthen protection and ensure long-term stable operation

The surface has undergone anti-corrosion treatment such as hot-dip galvanizing and electrostatic spraying, which combines wear resistance and rust resistance. It is suitable for harsh environments such as cold chain, outdoor, and chemical industries, significantly extending its service life. In response to practical risks, steel foot guards can be installed at the bottom of the column, combined with anti tipping devices and anti-collision guardrails, effectively resisting external forces such as forklift collisions and earthquake impacts. At the same time, strict adherence to safety factor standards of 1.5-1.8 times is required, with sufficient load redundancy reserved to eliminate structural instability hazards.